Pure tungsten powder offers the highest density, strength, and thermal properties among metals. This guide provides a detailed overview of unalloyed tungsten powder for industrial applications.

Saf Tungsten Tozuna Giriş

Pure tungsten powder contains >99.9% tungsten with minimal impurities. Key properties:

- Extremely high density of 19.3 g/cc

- Highest melting point of all metals – 3422°C

- Yüksek sıcaklık dayanımı

- Mükemmel ısı iletkenliği

- Düşük termal genleşme katsayısı

- İyi korozyon ve oksidasyon direnci

Benefits over alloyed powders:

- Superior thermal properties

- Improved electrical conductivity

- Higher density and purity

- Better sintered strength

- Avoidance of alloying elements

With its unsurpassed density and temperature resistance, pure tungsten enables high performance applications across industries.

Türleri Saf Tungsten Tozu

Various grades of pure tungsten powder:

Types of Pure Tungsten Powder

| Tip | Saflık | Parçacık Boyutu | Morfoloji |

|---|---|---|---|

| Saf | 99.9% W | 1-150 μm | Düzensiz, köşeli |

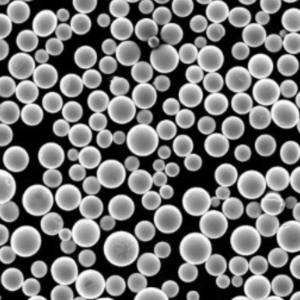

| Ultrafine | 99.9% W | <10 μm | Küresel |

| Nanopowder | >99.9% W | <100 nm | Küresel |

| Yüksek saflık | 99.95-99.99% W | 1-45 μm | Sponge-like |

Purity levels range from 99.9% to 99.999% tungsten content. Particle size, shape, and production method can be varied based on application.

Composition of Pure Tungsten Powder

Typical composition of pure tungsten powder:

- Tungsten (W) – 99.9% to 99.999%

- Oxygen (O) – 500-1000 ppm

- Carbon (C) – 100-300 ppm

- Nitrogen (N) – 20-100 ppm

- Hydrogen (H) – 20-100 ppm

- Potassium (K) – 20-50 ppm

- Sodium (Na) – 10-50 ppm

Higher purity grades minimize oxygen and other interstitials for better ductility and corrosion resistance.

Properties of Pure Tungsten Powder

Properties of Pure Tungsten Powder

| Mülkiyet | Değer |

|---|---|

| Yoğunluk | 19,3 g/cc |

| Erime noktası | 3422°C |

| Termal iletkenlik | 173 W/mK |

| Elektriksel direnç | 5.6 μΩ-cm |

| Çekme mukavemeti | 550-620 MPa |

| Elastik modül | 400 GPa |

| Termal genleşme katsayısı | 4.5 x 10-6/K |

The extreme density, thermal properties, strength, and temperature resistance make pure tungsten suitable for high performance applications.

Characteristics of Pure Tungsten Powder

Characteristics of Pure Tungsten Powder

| Parametre | Detaylar | Önem |

|---|---|---|

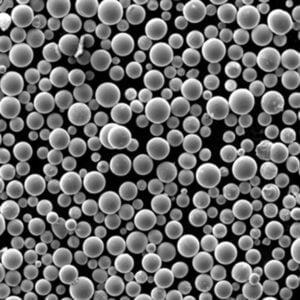

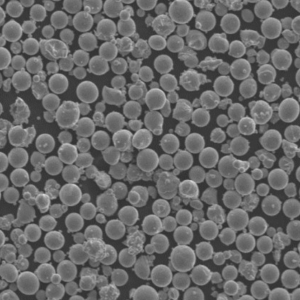

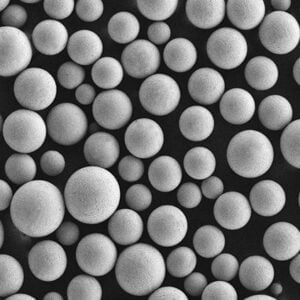

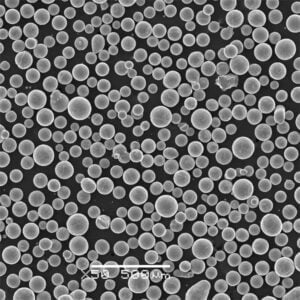

| Parçacık boyutu | 1-150 μm | Smaller sizes improve sintering |

| Parçacık şekli | Varied – angular, spherical | Impacts density and flow |

| Görünür yoğunluk | 3-4 g/cc | Indicates compaction properties |

| Musluk yoğunluğu | 9-11 g/cc | Yüksek paketleme yoğunluğu |

| Akış hızı | 20-25 s/50g | Measure of powder flowability |

| Oksijen içeriği | <1000 ppm | Affects ductility and strength |

Controlling size distribution, shape, surface area, density, and oxygen content is crucial for pure tungsten powder functionality.

Specifications of Pure Tungsten Powder

Pure Tungsten Powder Specifications

| Parametre | Değerler | Standart |

|---|---|---|

| Tungsten content | >99,9% | ASTM B763 |

| Parçacık boyutu | 1-10 μm | ASTM B213 |

| Görünür yoğunluk | >3 g/cc | ASTM B212 |

| Musluk yoğunluğu | >9 g/cc | MPIF 04 |

| Akış hızı | <25 s/50g | ASTM B213 |

| Oksijen içeriği | <1000 ppm | ASTM B939 |

Compliance with standardized specifications ensures batch-to-batch consistency and suitability for industrial applications.

Particle Sizes of Pure Tungsten Powder

Common particle size ranges:

Pure Tungsten Powder Particle Sizes

| Boyut | Açıklama | Tipik Kullanımlar |

|---|---|---|

| 1-10 μm | Ultrafine grade | Katmanlı üretim |

| 10-25 μm | İnce kalite | Powder injection molding |

| 25-45 μm | Orta sınıf | Kesici aletler |

| 45-150 μm | Kaba kalite | Tungsten ağır alaşımları |

Smaller particles sizes improve sintering and material properties but reduce flowability. Larger particles offer better packing density.

Sınıflar Saf Tungsten Tozu

Grades of Pure Tungsten Powder

| Sınıf | Purity (%W) | Oksijen (ppm) | Parçacık Boyutu (μm) |

|---|---|---|---|

| CP | 99.9 | 700-1200 | 1-150 |

| RMP | 99.95 | 400-800 | 1-45 |

| SP | 99.98 | 100-300 | 1-25 |

| EL-Grade | 99.99 | 50-150 | 1-10 |

CP – Crude powder, RMP – Reactor melt powder, SP – Sodium-reduced powder, EL-Grade – High purity

Higher purity reduces impurities and contamination for improved performance.

Global Standards for Pure Tungsten Powder

Key standards for pure tungsten powder:

- ASTM B763 – Standard specification for pure tungsten powder

- ISO 18274 – Chemical analysis of pure tungsten powders

- MPIF Standard 55 – Material standards for tungsten powder

- ASTM B939 – Guide to characterization of tungsten powder

- GB/T 4408 – Chinese standard for tungsten powders

These help ensure quality for different applications worldwide. Customized powders can also be produced as per requirements.

Applications of Pure Tungsten Powder

Applications of Pure Tungsten Powder

| Endüstri | Uygulama |

|---|---|

| Havacılık ve Uzay | Radyasyon kalkanı, karşı ağırlıklar |

| Otomotiv | Vibration damping in vehicles |

| Elektronik | Heat sinks, contacts, electrodes |

| Askeri | Kinetic energy penetrators, ordnance |

| Üretim | Cutting tools, dies, tooling |

| Petrol ve gaz | High density drilling mud additive |

Pure tungsten’s extreme density and temperature resistance make it ideal for high-performance parts and components across sectors.

Suppliers of Pure Tungsten Powder

Leading Suppliers of Pure Tungsten Powder

| Şirket | Konum |

|---|---|

| HC Starck | Germany, USA |

| Buffalo Tungsten | ABD |

| Ortabatı Tungsten | ABD |

| Plansee | Avusturya |

| Zhuzhou Cemented Carbide | Çin |

These established manufacturers offer various pure tungsten powder types and can customize grades based on purity, particle size, and property requirements.

Cost Analysis of Pure Tungsten Powder

Pure Tungsten Powder Pricing

| Sınıf | Kg başına fiyat |

|---|---|

| CP (99.9% W) | $100-150 |

| RMP (99.95% W) | $150-200 |

| SP (99.98% W) | $200-300 |

| EL-Grade (99.99% W) | $300-500 |

Pricing depends on purity, particle characteristics, supplier, and order volume. Prices are higher for finer particle sizes and higher purity.

Pros and Cons of Pure Tungsten Powder

Advantages of Pure Tungsten Powder

- Superior thermal conductivity and temperature resistance

- Improved strength and ductility over alloyed grades

- Highest density of all metallic powders

- Environmentally stable and inert

- Better finishing and surface roughness

- Can be recycled from scrap and waste

Limitations of Pure Tungsten Powder

- Very expensive compared to other powders

- Challenging to process due to high melting point

- Lower fracture toughness than alloyed tungsten

- Limited global supply and availability

- Requires handling precautions due to dust explosion risks

- Difficult to machine finished parts

For critical applications where performance outweighs cost, unalloyed tungsten is the material of choice. Proper precautions are necessary during handling and processing.

Comparison of Pure Tungsten Powder with Other Metals

Comparison With Alternative Metal Powders

| Parametre | Tungsten | Molibden | Tantal |

|---|---|---|---|

| Yoğunluk (g/cc) | 19.3 | 10.3 | 16.6 |

| Melting point (°C) | 3422 | 2617 | 2996 |

| Termal iletkenlik (W/mK) | 173 | 138 | 57 |

| Electrical resistivity (μΩ-cm) | 5.6 | 5.7 | 13 |

| Kg başına fiyat | $100-$500 | $30-$100 | $250-$500 |

Tungsten outperforms other refractory metals on key thermal and mechanical characteristics but with higher cost.

SSS

Q: How is pure tungsten powder produced?

A: Pure tungsten is mainly produced by reduction of tungsten oxide using hydrogen. Additional steps of crushing, milling, annealing, and blending achieve the desired powder characteristics.

Q: What is pure tungsten powder used for?

A: Key applications include radiation shielding, counterweights, tooling, cutting tools, grinding media, tungsten heavy alloys, electrical contacts, and heating elements.

Q: What precautions are needed when working with tungsten powder?

A: Tungsten powder poses explosion and inhalation risks requiring protective gear, ventilation, and inert gas glove boxes for storage and handling. Appropriate fire safety measures are essential.

Q: What are the different particle sizes available for pure tungsten powder?

A: Particle sizes range from 1-10 microns for ultrafine, 10-25 microns for fine, 25-45 microns for medium, and 45-150 microns for coarse fractions based on application requirements.

Q: Is pure tungsten powder more expensive than tungsten carbide?

A: Yes, pure tungsten powder costs 2-4 times higher than tungsten carbide powders. However, properties like higher density and electrical/thermal conductivity justify the added cost.

Q: What purity levels are commercially available?

A: Common purity levels are 99.9% (CP grade), 99.95% (RMP grade), 99.98% (SP grade), and 99.99% (EL grade) tungsten content. Higher purity further increases cost.

Q: Can pure tungsten powder be 3D printed?

A: Yes, high purity tungsten powders in the 10-45 micron range can be used for laser powder bed fusion and binder jetting additive manufacturing with proper parameter optimization.

Q: What post-processing steps are used for pure tungsten parts?

A: Sintered tungsten components are finished by grinding, lapping, polishing, and other methods to achieve tight dimensional and surface tolerance requirements.