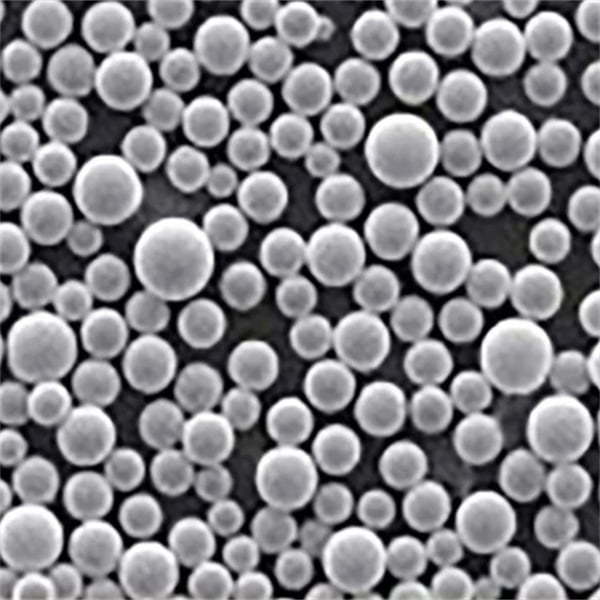

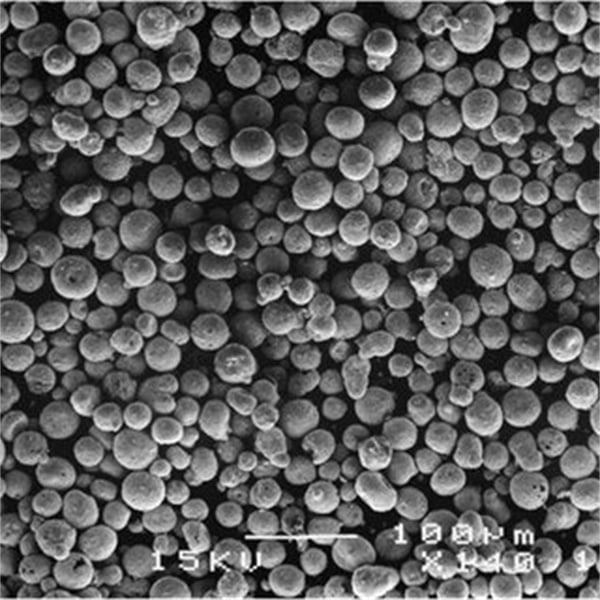

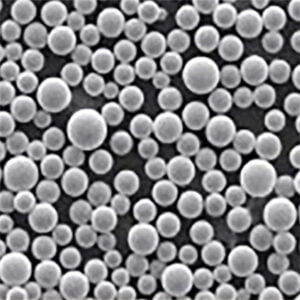

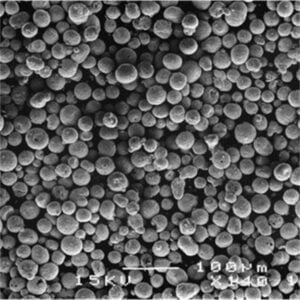

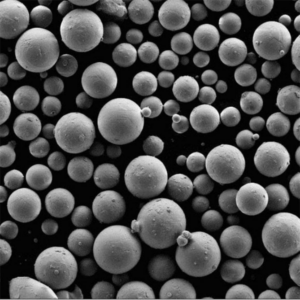

Alüminyum Bakır 3D Metal Tozunun Özel Uygulamaları

The world of 3D printing continues to evolve at a breakneck pace, constantly pushing the boundaries of what’s possible. Imagine a material that combines the lightweight sturdiness of aluminum with the exceptional electrical conductivity of copper. That’s the magic of aluminum copper 3D metal powder, a revolutionary material unlocking a