Обзор Metal Atomization

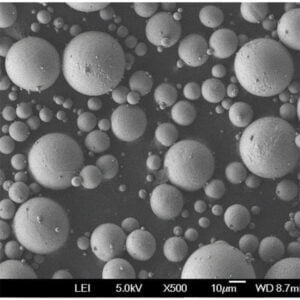

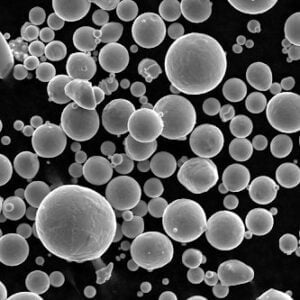

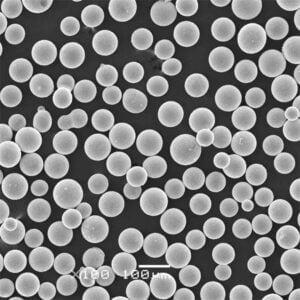

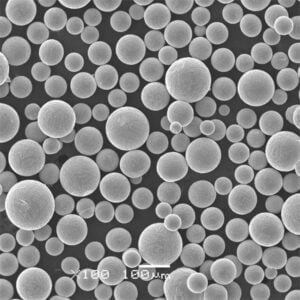

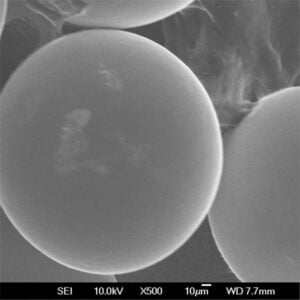

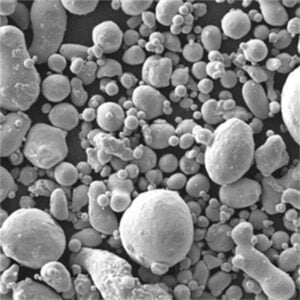

Metal atomization is a process where molten metal is broken into fine droplets using gas or liquid that is forced at high velocity. The droplets rapidly solidify into powder with a spherical or round morphology ideal for additive manufacturing or metal injection molding.

Atomization produces consistent powder sizes ranging from 10 microns to 200+ microns based on the nozzle design and operating pressures. Nitrogen, argon or air is typically used for gas atomization while water is common in liquid atomization.

Виды Metal Atomization Процессы

| Процесс | Средний | Размер частиц | Металлы |

|---|---|---|---|

| Газовая атомизация | Азот, аргон | 10-100 мкм | Титан, алюминий, нержавеющая сталь |

| Вакуумное распыление | Азот, аргон | 10-63 мкм | Nickel superalloys, titanium aluminide |

| Распыление воды | Вода | 100-350 μm | Low alloy steel, stainless steel |

Технические характеристики

| Параметр | Подробности |

|---|---|

| Уровень производства | 1-20 metric tons per hour |

| Давление газа | Up to 35 bar |

| Перегрев расплава | 100-250°C above liquidus |

| Powder yield | 60-95% depends on metal |

| Скорость охлаждения | 10^3 to 10^6 °C/s |

Применение Распыляемые металлические порошки

Some uses of atomized powders include:

- 3D Printing powders for SLM and DMLS

- Metal Injection Molding (MIM) feedstock

- Термические напыляемые покрытия

- Production of sintered parts

- Brazing pastes or joining applications

- Chemical/petroleum catalytic converters

Global metal atomizer manufacturer

| Компания | Расположение |

|---|---|

| AP&C | Канада |

| Praxair | США |

| Sandvik | Швеция |

| Mattersmith | Китай |

| Phoenix Scientific Industries | Индия |

Leading Manufacturers of Atomized Metal Powders

| Компания | Материалы |

|---|---|

| Sandvik | Nickel, titanium, stainless steel alloys |

| Столярная присадка | Titanium alloys, cobalt chrome, stainless steels |

| Технология LPW | Aluminum, titanium, copper alloys |

| EOS | Tool steel, cobalt chrome, inconel, titanium alloys |

| AP&C | Reactive metals like titanium, aluminum grades |

Соображения по поводу стоимости

A gas atomization system with capacity of 500-1000 kg/hour costs around $2-4 million depending on complexity, metal type, level of automation and additional powder handling equipment. Payback period can vary from less than 2 years to 5+ years depending on scale of production.

Atomized powder pricing depends on composition, quality level, lot quantity, reuse status and prevailing raw material costs. For instance, virgin titanium Ti64 grade 5 powder of size 45-100 microns suitable for 3D printing sells for $200-500 per kg.

Advantages of Atomization

- Consistent spherical powder morphology beneficial for AM and MIM applications

- Cost-effective high volume powder production with minimal scrap losses

- Custom alloys and powder characteristics achievable

- Powder fully recyclable for reuse in most applications

- Rapid cooling gives fine microstructures and controlled powder sizes

Ограничения

- High capital investment for turnkey atomization production systems

- Additional powder sieving, blending or modification required

- Limited size range and high reactivity restricts some alloys

- Safety issues like dust explosivity must be addressed

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

Q: What is the difference between gas and water atomized powders?

A: Gas atomized powders are finer (<100 μm), more spherical and smoother than irregular, coarser water atomized powders but gas atomization systems have higher setup costs.

Q: Which industries consume the major share of atomized metal powders?

A: Over 60% of fine atomized powders are estimated to be used in metal additive manufacturing processes like selective laser sintering, laser melting and binder jetting.

Q: What is vacuum induction melting used for prior to atomization?

A: Vacuum induction melting allows melting reactive alloys like titanium or stainless steel under inert conditions preventing contamination which is critical for producing clean high purity atomized powders.

Q: Does post-processing further modify properties of atomized powders?

A: Yes, additional steps like thermal annealing, hot isostatic pressing, plasma spheroidization, sieving or mixing are performed to tailor particle size distribution, flowability, density or composition characteristics as needed for downstream processes.

Q: How is powder reuse economical for atomization process?

A: Atomized powders can cost anywhere from $20 per kg for steel to $500 per kg for exotic alloys. Capturing and reusing overflows and used build powders from AM machines using screening, thermal vacuuming, etc. lowers overall operating costs.