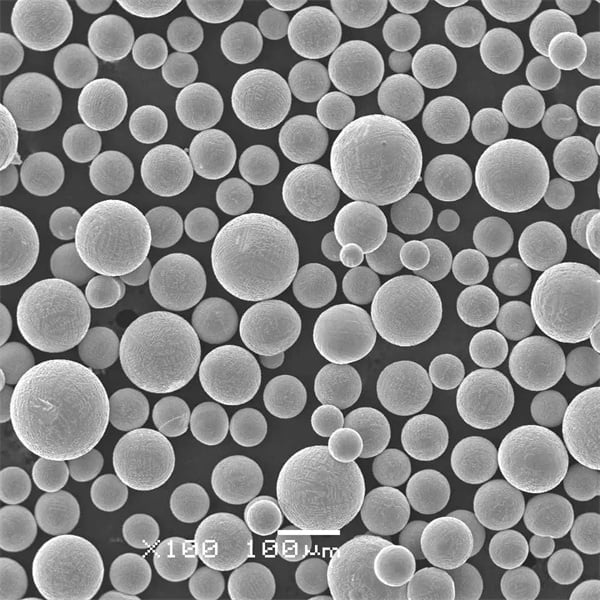

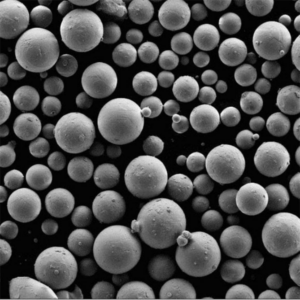

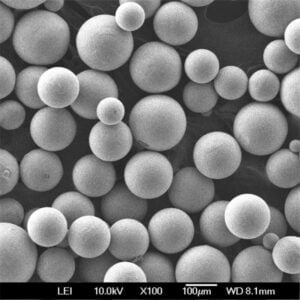

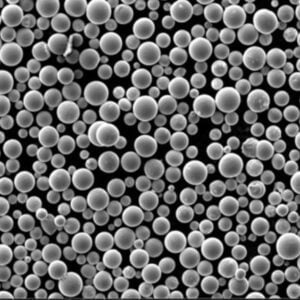

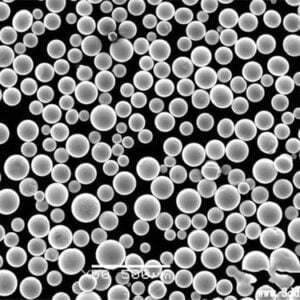

GH5188 Powder

GH5188 is a W-strengthened diamond-based high-temperature alloy. GH5188 has good mechanical properties and excellent high temperature oxidation resistance. It is suitable for aviation parts that require tensile strength below 980°C and oxidation resistance below 1100°C.

Low MOQ

Provide low minimum order quantity to meet different needs.

OEM & ODM

Provide customized products and design services to meet unique customer needs.

Adequate Stock

Ensure fast order processing and provide reliable and efficient service.

Customer Satisfaction

Provide high quality products with customer satisfaction at the core.

share this product

Table of Contents

GH5188 is a W-strengthened diamond-based high-temperature alloy. GH5188 has good mechanical properties and excellent high temperature oxidation resistance. It is suitable for aviation parts that require tensile strength below 980°C and oxidation resistance below 1100°C.

Physical Properties

|

Size range

|

Size distribution |

Hall flow rate

|

Bulk density

|

Tap density

|

||

| D10(μm) | D50(μm) | D90(μm) | ||||

| 15-53μm | 17-22 | 32-38 | 52-58 | ≤18s/50g | ≥4.80g/cm³ | ≥5.40g/cm³ |

Heat Treatment Recommendations

Solid solution treatment:1180±20°C/1h/AC

Mechanical Behavior

| Test temperature | Tensile strength (σb/Mpa) | Yield strength (σp0.2/Mpa) |

Elongation (δ5/%)

|

| 25℃ | 900 | 400 | ≥45 |

| 650℃ | 650 | 280 | ≥50 |

| 900℃ | 300 | 240 | ≥50 |

| 950℃ | 200 | 170 | ≥50 |

| 1000℃ | 160 | 130 | ≥50 |

Chemical Composition Range (Wt,-%)

| Element | C | Cr | Ni | Co | W | Fe |

| wt% | 0.05-0.15 | 20.00-24.00 | 20.00-24.00 | Bal | 13.00-16.00 | ≤3.00 |

| Element | B | La | Mn | Si | P | S |

| wt% | ≤0.015 | 0.03-0.12 | ≤1.25 | 0.20-0.50 | ≤0.02 | ≤0.015 |

| Element | Cu | O | N | – | – | – |

| wt% | ≤0.07 | ≤0.025 | ≤0.015 | – | – | – |

Get Latest Price

About Met3DP

Product Category

HOT SALE

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.