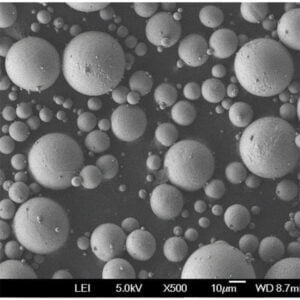

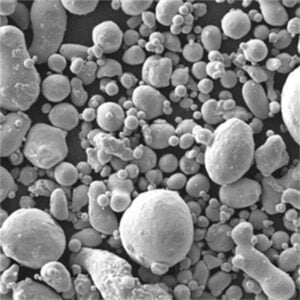

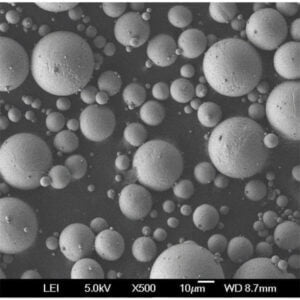

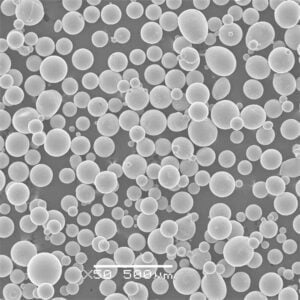

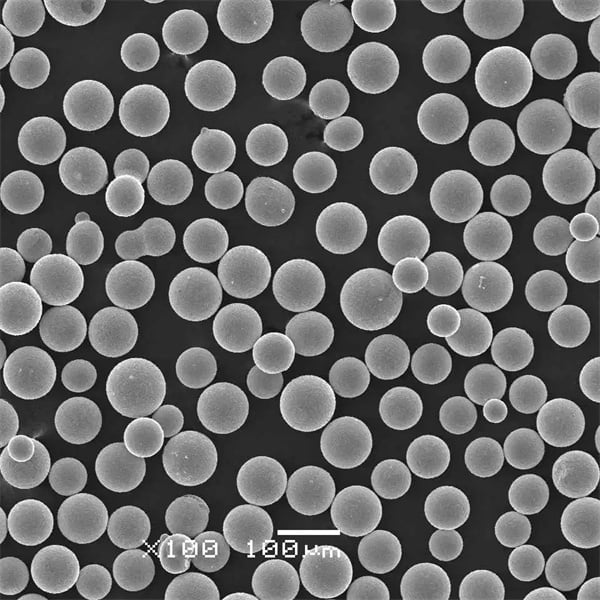

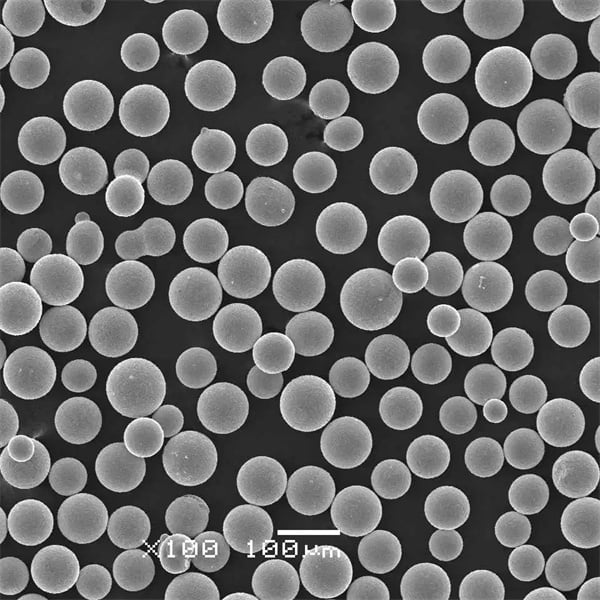

Nickel spherical powders are a specialized type of metal powder used in various industrial applications. These powders consist of tiny, spherical particles made from pure nickel or nickel alloys. Their unique shape and composition make them highly desirable for processes that require precise control over particle size, flowability, and packing density.

Imagine a collection of microscopic ball bearings, each one a perfectly round nickel sphere. These powders are engineered to meet stringent specifications, ensuring consistent performance and quality in the products they’re used to manufacture.

Production Methods of Nickel Spherical Powders

| Method | Description | Pros | Cons | Applications |

|---|---|---|---|---|

| Gas Atomization | Melted nickel, blasted by high-pressure gas, disintegrates into droplets that solidify as they cool, forming spheres. | – Excellent sphericity & size distribution – High purity & tap density | – High cost & complex process | Powder metallurgy, thermal spraying, 3D printing |

| Chemical Vapor Deposition (CVD) | Nickel precursor vaporizes and reacts on a substrate, building spherical layers. | – High purity & controlled morphology | – Expensive & intricate process | Electronic devices, catalysts |

| Electrodeposition | Electric current draws nickel ions from a solution, depositing them as spheres on a cathode. | – Cost-effective & simple operation | – Lower sphericity & wider size variation | Batteries, magnetic materials |

| Solvothermal Method | Controlled heating & pressure convert dissolved nickel precursors into spheres within a solvent. | – Tailorable morphology & size | – Limited production scale & high cost | Biomedical applications, advanced materials |

| Ultrasonic Atomization | High-frequency sound waves break down liquid nickel into droplets, solidifying into spheres. | – Simple & versatile | – Lower sphericity & broader size range | Coatings, fuel additives |

| Microemulsion Method | Nickel precursor dispersed in oil & water mixture forms spheres stabilized by surfactants. | – Uniform particle size & narrow distribution | – High equipment cost & complex setup | Functional materials, drug delivery systems |

Composition and Properties of Nickel Spherical Powders

| Property | Description |

|---|---|

| Composition | Pure nickel or nickel alloys (e.g., Ni-Cu, Ni-Sn, Ni-P) |

| Particle Size | Typically ranging from 5 to 200 microns |

| Particle Shape | Highly spherical with a smooth surface |

| Density | Higher density compared to irregular powders |

| Flowability | Excellent flowability due to the spherical shape |

| Packing Density | High packing density for optimal material utilization |

| Electrical Conductivity | Excellent electrical conductivity, depending on alloy composition |

| Corrosion Resistance | Good corrosion resistance, especially in nickel-rich alloys |

These spherical powders are produced using advanced manufacturing techniques, such as gas atomization or plasma rotating electrode process (PREP), which ensure precise control over particle size, shape, and composition.

Industrial Applications of Nickel Spherical Powders

| Application | Description |

|---|---|

| Metal Injection Molding (MIM) | Used as feedstock for MIM processes to produce complex, high-precision metal components |

| Additive Manufacturing (3D Printing) | Employed in powder bed fusion processes (e.g., selective laser sintering) for additive manufacturing |

| Thermal Spray Coatings | Used in thermal spray processes for applying wear-resistant, corrosion-resistant coatings |

| Electrical and Electronic Applications | Used in conductive coatings, electrodes, and other electrical components |

| Battery Materials | Utilized as active materials or conductive additives in battery manufacturing |

| Catalysts and Catalytic Converters | Employed as catalysts or catalyst supports in various chemical processes |

The unique properties of nickel spherical powders, such as their high packing density and excellent flowability, make them ideal for processes that require precise material handling and uniform distribution of particles.

Specifications and Standards for Nickel Spherical Powders

| Parameter | Specification |

|---|---|

| Particle Size Distribution | Customizable based on application requirements |

| Sphericity | Typically > 0.9 (where 1.0 is a perfect sphere) |

| Apparent Density | Ranging from 2.5 to 5.0 g/cm³ |

| Chemical Composition | Tailored to meet specific alloy requirements |

| Impurities | Stringent limits on impurities like carbon, oxygen, and sulfur |

Reputable manufacturers adhere to industry standards, such as ASTM, ISO, and SAE, to ensure consistent quality and performance of their nickel spherical powders.

Suppliers and Pricing of Nickel Spherical Powders

| Supplier | Location | Price Range (USD/kg) |

|---|---|---|

| Carpenter Powder Products | United States | $25 – $60 |

| Sandvik Materials Technology | Sweden | $30 – $70 |

| Höganäs AB | Sweden | $28 – $65 |

| Rio Tinto | Canada | $35 – $75 |

| Kulzer GmbH | Germany | $40 – $80 |

Pricing for nickel spherical powders can vary significantly based on factors such as purity, alloy composition, particle size distribution, and order quantity. It’s essential to work with reputable suppliers to ensure consistent quality and reliable supply.

Pros and Cons of Nickel Spherical Powders

| Pros | Cons |

|---|---|

| Excellent flowability | Higher cost compared to irregular powders |

| High packing density | Potential health and environmental concerns |

| Consistent particle size and shape | Limited availability of certain alloy compositions |

| Good electrical and thermal conductivity | Specific handling and safety requirements |

| Corrosion resistance (nickel-rich alloys) | Potential for agglomeration or oxidation |

While nickel spherical powders offer numerous advantages in terms of performance and processability, their higher cost and potential health and environmental concerns should be carefully considered.

FAQs

| Question | Answer |

|---|---|

| What is the typical particle size range for nickel spherical powders? | Nickel spherical powders typically range from 5 to 200 microns in particle size, but can be customized based on application requirements. |

| How are nickel spherical powders produced? | They are produced using advanced manufacturing techniques such as gas atomization or plasma rotating electrode process (PREP), which ensure precise control over particle size, shape, and composition. |

| What are the main advantages of using nickel spherical powders? | The main advantages include excellent flowability, high packing density, consistent particle size and shape, good electrical and thermal conductivity, and corrosion resistance (for nickel-rich alloys). |

| Are there any health or environmental concerns associated with nickel spherical powders? | Yes, there are potential health and environmental concerns related to the handling and disposal of nickel-containing materials. Proper safety measures and responsible waste management practices should be followed. |

| How do nickel spherical powders compare to irregular powders in terms of cost? | Nickel spherical powders are generally more expensive than irregular powders due to the specialized manufacturing processes involved and their enhanced performance characteristics. |