Nickel carbonate powder is an important industrial chemical with a wide range of uses. This article provides an overview of nickel carbonate powder and its key properties, applications, specifications, pricing, and more.

Overview of Nickel Carbonate Powder

Nickel carbonate, chemical formula NiCO3, is an inorganic salt that forms a pale green powder under standard conditions. Some key details about nickel carbonate powder include:

Composition

- Primarily composed of nickel, carbon, and oxygen

- Typically contains 57-59% nickel

- Available in technical and pure grades

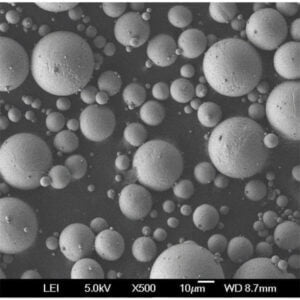

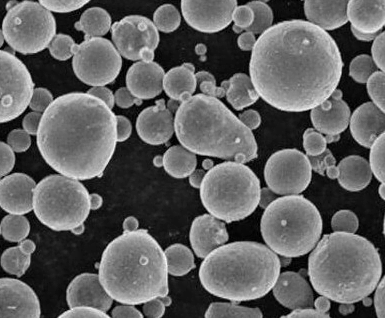

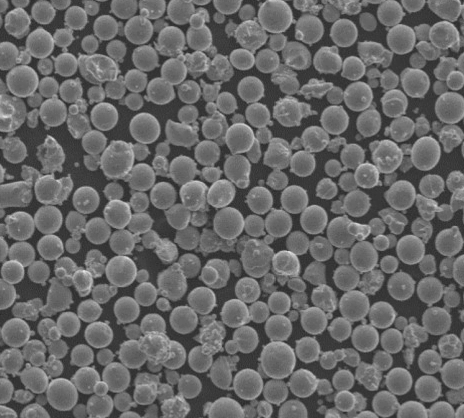

Key Characteristics

- Fine green crystalline powder

- Density around 3.7-3.9 g/cm3

- Melting point decomposes at 240°C before melting

- Soluble in acids, ammonia; insoluble in water

- Non-combustible with no flash point

Typical Impurities

- Iron, sulfur, chloride, silica

- 1-3% for technical, less than 1% for pure grades

Hazards

- Low acute toxicity

- Chronic exposure may cause skin sensitization, respiratory irritation

Applications

- Electroplating – dull nickel deposits

- Ceramics – pigments, glazes

- Catalyst precursor

- Batteries – nickel electrodes

- Other uses

Nickel carbonate’s versatility as a chemical intermediate makes it useful across industries like electroplating, ceramics, catalysis, and batteries.

Types of Nickel Carbonate Powder

Nickel carbonate powder is available in different grades for technical and high purity uses:

| Types | Nickel Content | Impurities | Particle Size | Typical Uses |

|---|---|---|---|---|

| Technical | 57-59% | Higher | Powder to granules | Electroplating, ceramics |

| Pure / Refined | Min 59% | Lower (<1%) | Very fine powder | Catalyst, batteries |

There are also different forms of nickel carbonate powder regarding composition:

| Forms | Composition | Properties | Uses |

|---|---|---|---|

| Basic nickel carbonate | 2NiCO3.3Ni(OH)2.xH2O | Greenish tint, higher nickel content | Preferred for plating |

| Neutral nickel carbonate | NiCO3 | Gray-green, lower nickel | Some technical uses |

This table compares some properties between the basic and neutral forms:

| Property | Basic Nickel Carbonate | Neutral Nickel Carbonate |

|---|---|---|

| Solubility in ammonia | Soluble | Insoluble |

| Nickel content | Higher (~58%) | Lower (~50%) |

| Stability | Less stable | More stable |

| Price | Higher | Lower |

So in summary, there are technical and high purity grades, basic and neutral compositional forms, and differences in powder characterstics to suit end applications.

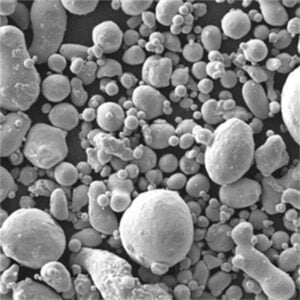

Production Methods

The main production routes for nickel carbonate powder include:

- Direct carbonation – Reaction of nickel oxide with carbon dioxide gas

- Indirect carbonation – Ammonia process with nickel matte

- Substitution method – Ion exchange reaction starting from nickel chloride or sulfate

The table below shows a comparison between methods:

| Production Route | Raw Materials | Typical Nickel Content | Impurities | Scalability |

|---|---|---|---|---|

| Direct carbonation | Nickel oxide | 57-59% | Medium | Smaller batches |

| Indirect carbonation | Nickel matte | 57-59% | Low | Large scale |

| Substitution method | Nickel salts | 57-60% | Very low | Flexible |

The direct carbonation approach is a straightforward process but can introduce impurities from lower grade nickel oxide. The indirect ammonia process utilizes very pure nickel matte feedstock. The substitution method offers great purity and flexibility but requires additional nickel salt raw materials.

Specifications

Nickel carbonate powder is available under various international specifications and standards:

| Standards | Minimum Nickel (%) | Maximum Impurities | Particle Size (Mesh) |

|---|---|---|---|

| ASTM B154 | 57 | 3% Fe,1% S,1% insol | >100 mesh |

| GB/T 3562 | 58 | 1.7% Fe,1% Cl,1% S | – |

| QC/T 783-2008 | – | 0.005% Co;0.01% Cu;1% insol | – |

Nickel carbonate specifications list requirements on chemical composition, minimum nickel content, limits on iron, sulfur and other impurities present, as well as powder particle size distribution.

Grades

Nickel carbonate grades by nickel content (%):

- Low: 50-56%

- Standard: 57-59%

- High purity: Min 59%+

Finer distinctions may be made between technical, industrial, pure etc. grades based on impurity levels and use requirements.

Packaging

Common packaging options:

- Small bags / containers – 1kg, 5kg, 25kg

- Drums – Typically 50kg, 100kg

- Super sacks – 500kg to 1500kg

Packaging material is usually plastic or plastic-lined bags/containers. Larger quantities are shipped in secured drums or super sacks. Custom packaging may be possible for bulk users.

Pricing

Pricing estimate for nickel carbonate powder (USD per metric ton):

| Grade | Purity | Price Range |

|---|---|---|

| Technical | 57-58% Ni | $14,000 – $16,000 |

| Refined | Min. 59% Ni | $17,000 – $19,000 |

| High Purity | >99% | $21,000 – $25,000 |

Key factors influencing nickel carbonate pricing:

- Nickel prices – Directly linked to LME nickel index prices

- Purity – Higher purity commands premium pricing

- Quantity – Large volume purchases usually get discounted rates

- Geographic location – Regional supply and demand dynamics

Up-to-date pricing is best obtained from nickel carbonate suppliers and distributors directly based on grade, volume, etc.

Applications and Uses

Major industrial applications and uses of nickel carbonate powder include:

Electroplating

- Used to deposit dull or semi-bright nickel coatings

- Less expensive than nickel sulfate and chloride

- Basic nickel carbonate preferred to avoid impurities affecting plating quality

Ceramics

- Source of nickel for coloring glazes and ceramic pigmentation

- Provides unique greens, browns, yellows, and metallic effects

Catalyst Precursor

- Converted to nickel metal or nickel oxide used in catalysts

- Hydrogenation, dehydrogenation, and desulfurization catalysts

Batteries

- Cathode material in nickel electrodes for rechargeable nickel batteries

- Requires very high purity refined basic nickel carbonate

Other Uses

- Manufacture Nickel Salts – nickel sulfate, acetate, chloride etc.

- Alloys and metal products

- Glass coloring and polishing

- Magnetic materials

- Portland cement additive

This table summarizes some application-specific technical specifications:

| Application | Grade Needed | Typical Nickel Content | Impurity Limits | Particle Size |

|---|---|---|---|---|

| Electroplating | Basic | 57-58% | Lower iron | Granules, powder |

| Ceramics | Either | 57-59% | Relaxed | – |

| Catalyst | High purity | Min 99% | Very low | – |

| Batteries | High purity, basic | 99.9-99.99% | Extremely low | Ultrafine <1 micron |

So in different areas, nickel carbonate powder is processed into end products for industries from metal plating to high performance batteries.

Suppliers and Manufacturers

Some leading global suppliers and manufacturers of nickel carbonate powder include:

| Company | Locations | Production Capacity | Typical Products |

|---|---|---|---|

| Jilin Jien Nickel Industry Co., Ltd. | China | 20,000 mt | Technical, pure grades |

| INCO Limited | Canada | 10,000 mt | Battery, catalyst grades |

| Chengtun Group | China | 10,000 mt | Low/high grade |

| Umicore | Europe, Asia | NA | High purity |

| American Elements | USA | NA | High purity |

Distributors and Resellers

- Alpha Chemicals

- American Elements

- Glentham Life Sciences

- Hefei TNJ Chemical

- Loba Chemie

- Strem Chemicals

- Shanghai Ruizheng Chemical

- BeanTown Chemical

- Career Henan Chemical

Advantages of Nickel Carbonate

Some of the main benefits and advantages of using nickel carbonate powder vs other nickel compounds:

| Advantages | Details |

|---|---|

| Lower cost | Less expensive than nickel sulfate or nickel chloride |

| Easier handling | Less hygroscopic than nickel chloride which absorbs moisture rapidly |

| Fewer impurities | Contains less problematic elements like sodium, calcium, magnesium than other nickel salts |

| Stable composition | Basic form nickel carbonate maintains uniform Ni:CO3 ratio during processing |

| Uniform deposits | Basic nickel carbonates provide smooth, matte nickel coatings from plating baths without pitting |

| Easy dispersion | No caking issues – disperses well in aqueous plating solutions |

Key reasons why nickel carbonate is preferred in some applications come down to economics, handling, consistency, and performance factors.

Versus Nickel Sulfate

Comparing nickel carbonate to sulfate:

- Lower price point

- Less soluble but easier to filter residues

- Produces darker nickel plate

- Can introduce sulfur-based defects in deposits impacting ductility

Versus Nickel Chloride

Comparing nickel carbonate to chloride:

- Much lower cost

- No hydroscopic moisture absorption issues during storage

- Less corrosive to equipment like plating tanks

- Produces plate with poorer ductility than chloride solutions

Summary

While nickel sulfate and chloride have areas where their plating performance shines, carbonate offers the best all-round combination of affordability, handling, and deposit quality making it a versatile plating chemical.

Limitations of Nickel Carbonate

| Drawbacks | Elaboration |

|---|---|

| Insolubility | Has relatively low solubility which can require agitation, heating or ammonia to fully dissolve in plating solutions |

| Slow dissolution | Dissolution rate weaker than other soluble nickel salts – needs process adjustments |

| Impurities | Technical grades may contain impurities affecting quality |

| Toxicity | Inhalation risks if powders are not controlled |

Plating Challenges

Some specific limitations when using nickel carbonate powder for electroplating vs alternatives:

- Requires higher pH bath chemistry for dissolution

- Can introduce foreign elements like iron affecting deposits

- Larger filtration requirements to capture undissolved particles

- Longer dissolution times which reduce plating production throughput

- Surface quality lower than sulfate or chloride-based plating

- Final plate ductility not as high as sulfate or chloride

However, these limitations are mitigated by correct bath preparation, filtration, and process controls.

Mitigation Measures

- Start with higher purity basic nickel carbonate powder where possible

- Use ammonia, heating, agitation to improve dissolution

- Employ magnetic separators or efficient filtration to remove particulate contamination

- Pre-dissolve powder in nickel plating solution before adding to plating bath

- Adjust operating parameters – pH, temperature, current density to improve quality

- Consider using nickel carbonate along with sulfate or chloride salts to balance cost and performance

Safety and Toxicity

Nickel carbonate powder requires safe handling practices:

- Dust inhalation – Use respiratory protection; avoid dust generation

- Skin contact – Wear gloves; wash affected areas

- Eye contact – Wear safety goggles; rinse eyes if exposed

- Ingestion – Do not consume; wash mouth out if consumed

Exposure Guidelines

- OSHA PEL 1 mg/m3 (Nickel)

- ACGIH TLV 0.1 mg/m3 (Nickel)

Toxicity Data

- Low acute oral/dermal toxicity

- May trigger skin sensitization with repeated contact

- Higher chronic toxicity risks the purer the grade

Always check Safety Data Sheets (SDS) from suppliers for up to date, detailed safety information before handling or processing nickel carbonate powder.

FAQs

Q: Is nickel carbonate natural or synthetic?

A: Commercially available nickel carbonate is produced synthetically by chemical conversion of nickel containing ores. Natural nickel carbonate mineral is very rare.

Q: What is basic vs neutral nickel carbonate?

A: Basic nickel carbonate contains nickel hydroxide while neutral form is pure NiCO3. Basic types have higher nickel content and better plating properties.

Q: What is nickel carbonate used for?

A: Major uses are electroplating to deposit nickel layers, ceramics for coloration and glazes, catalyst precursor material, and nickel metal batteries.

Q: Is nickel carbonate hazardous?

A: It has low acute toxicity but long term exposure carries higher chronic toxicity risks from nickel accumulation and inhalation. Proper PPE should be used when handling.

Q: What are common nickel carbonate industry standards?

A: Key nickel carbonate powder specs are governed by standards like ASTM B154, GB/T 3562, and QC/T 783-2008 covering composition, purity, and nickel levels.

Q: What does nickel carbonate react with?

A: It reacts with mineral acids to form nickel salts. Turns brown-black slowly in moist air from surface nickel hydroxide formation. Decomposes before melting at high temperatures. Use care with alkalis.

Q: Is nickel carbonate soluble in water?

A: No, nickel carbonate has a very low solubility in water. It requires heated acidic plating solutions or ammonia to fully dissolve for applications like electroplating.

Q: What are some alternatives to using nickel carbonate?

A: Depending on application, alternatives include – nickel sulfate, nickel chloride for plating; nickel oxide, nickel hydroxide for batteries; other nickel compounds for catalysts.