Nickel based powders refer to powders made from nickel or nickel alloys that are used in various applications such as additive manufacturing, surface coating, welding, and more. This article provides an overview of nickel based powders, their composition and properties, applications, specifications, pricing, comparisons, and FAQs.

Overview of nickel based powders

Nickel based powders are metallic powders composed primarily of nickel along with alloying elements like chromium, molybdenum, tungsten, and others. Key properties that make these powders suitable for high performance applications are:

- High strength and hardness at elevated temperatures

- Excellent corrosion and oxidation resistance

- Good wear resistance

- High thermal and electrical conductivity

- Low coefficient of thermal expansion

These powders can be produced through processes like gas or water atomization, electrolysis, carbonyl decomposition etc. in various sizes and morphologies. Common nickel alloys used are Inconel, Monel, Hastelloy, Nichrome etc.

nickel based powders Composition

Nickel based powders contain nickel as the main element along with other alloying elements. Typical compositions are:

| Alloy | Nickel (%) | Other Elements |

|---|---|---|

| Nickel | 99%+ | – |

| Inconel | 72% Ni, 14-17% Cr | Iron, niobium, copper, aluminum |

| Monel | 63-70% Ni, 27-34% Cu | Iron, manganese, silicon, carbon |

| Nichrome | 80% Ni, 20% Cr | Iron |

| Hastelloy | 42-62% Ni | Chromium, molybdenum, tungsten |

The ratio of nickel and alloys determines the key characteristics like strength, corrosion resistance, oxidation resistance, etc.

nickel based powders Properties

Nickel alloy powders offer exceptional properties compared to nickel which makes them suitable for harsh environments:

| Property | Characteristics |

|---|---|

| High temperature strength | Retain strength and resist creep deformation at over 1000°C |

| Corrosion resistance | Form protective oxide layer, resistant to acids, alkalis etc. |

| Oxidation resistance | Slow rate of oxidation in air up to ~1100°C |

| Wear resistance | Resist erosion, abrasion, galling better than steel |

| Thermal conductivity | Higher than stainless steels, ~20 W/m.K for Inconel 625 |

| Electrical resistivity | Range of alloys have high resistivity for heating elements |

| Coefficient of thermal expansion | Low CTE provides thermal shock resistance |

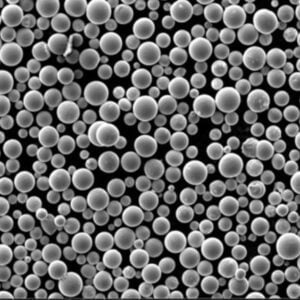

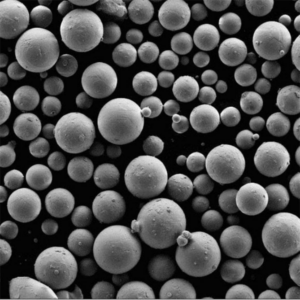

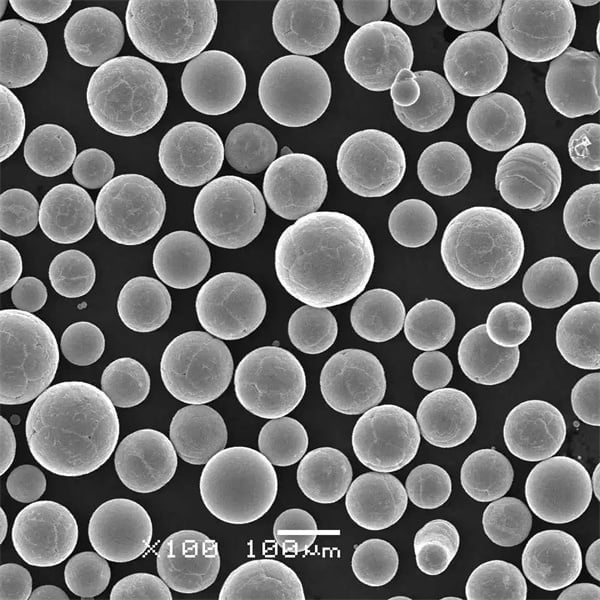

Types of nickel based powders

Nickel powders are available in different types suitable for various methods of deposition:

| Type | Common Alloys | Size Range | ** Morphology** |

|---|---|---|---|

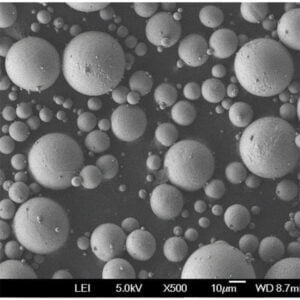

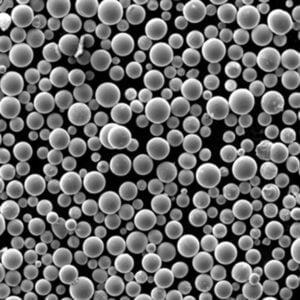

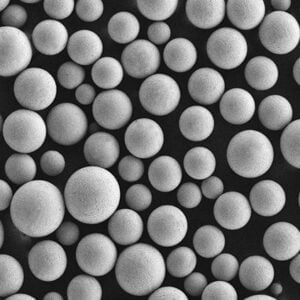

| Gas Atomized | Inconel 625, 718; Monel, Hastelloy | 5 – 150 μm | Rounded, spherical |

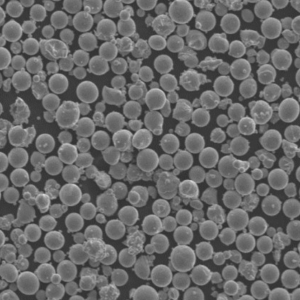

| Water Atomized | Inconel 625, 718; 316L, 304L | 10 – 300 μm | Jagged, irregular |

| Electrolytic | Nickel, Monel, Nichrome | 1 – 150 μm | Dendritic, crystalline |

| Carbonyl | Nickel | 0.5 – 12 μm | Flakes, chips |

- Gas and water atomized allow better packing density and flowability

- Electrolytic have higher oxygen content which causes porosity

- Carbonyl nickel powder has high purity (>99% Ni)

nickel based powders Applications

Major application areas of nickel alloy powders include:

| Industry | Applications |

|---|---|

| Additive Manufacturing | Aerospace components, turbine blades, rocket engines |

| Welding | Repair of turbines, tools, molds; joining inconel, hastelloy |

| Surface Coating | Corrosion protection, wear resistance, overlay coatings |

| Electronics | Resistors, heating elements, conductors |

| Diamond tools | Bonding diamond grits for cutting, drilling, grinding |

| Magnets | Improving magnetic properties |

| Batteries | Nickel electrodes in Ni-Cd, Ni-MH batteries |

Unique properties like high strength and corrosion resistance allow nickel powders to enable critical applications.

nickel based powders Specifications

Nickel alloy powders are available in various sizes, morphologies and must meet composition, purity and consistency specifications for reliable performance.

| Parameter | Range/Grades |

|---|---|

| Particle size | 5 μm to 300 μm |

| Particle shape | Spherical, irregular, flakes |

| Apparent density | 2 – 5 g/cc |

| Tap density | 4 – 7 g/cc |

| Flow rate | 15 – 25 s/50g |

| Purity | 98.5% to 99.9% |

| Oxygen content | <0.5% |

| Hydrogen loss | <0.1% |

Standards organizations like ASTM International provide specifications on testing methods and thresholds for nickel powders:

- ASTM B162: Standard for Nickel Plate, Sheet, Strip and Rolled Bar

- ASTM B283: Gas Atomized Nickel Powder and Powder Metallurgy Products

- ISO 4499-4: Metallic powders – Determination of oxygen and nitrogen contents by hot extraction

nickel based powders Suppliers and Pricing

Some leading global suppliers of nickel and nickel alloy powders are:

| Company | Brands | Alloys | Price Range |

|---|---|---|---|

| Hoganas | Nicopowder® | Nickel, carbonyl nickel | $50 – $100 per kg |

| Sandvik Osprey | Nifco® | Nickel, copper nickel, nickel iron | $75 – $250 per kg |

| Carpenter Technology | Cartech® | 625, 718, 690,Monel, Hastelloy | $100 – $500 per kg |

| AMETEK | Ultrafine nickel | Carbonyl nickel | $80 – $120 per kg |

Pricing varies based on:

- Alloy grade: Inconel 718 > Inconel 625 > Nickel > Monel

- Particle size: Nano powder > Micro powder

- Purity levels: 99.9% Nickel > 98% Nickel

- Quantity and bulk discounts

Comparisons

| Parameters | Gas Atomized | Water Atomized | Electrolytic |

|---|---|---|---|

| Cost | High | Low | Medium |

| Purity | High – 99%+ | Medium – 98-99% | Low – 90-98% |

| Oxygen Pickup | Low | High | High |

| Particle Shape | Rounded | Jagged | Dendritic |

| Flowability | Excellent | Moderate | Poor |

| Apparent Density | High | Medium | Low |

| Applications | AM, coatings | Welding, surface coatings | Heating elements, electronics |

Key differences in production process lead to tradeoffs in cost, quality and performance.

Advantages of nickel based powders

Nickel alloy powders provide unique benefits over other materials:

- Withstand high temperatures exceeding 1000°C

- Resist corrosion in acidic or alkaline environments

- Enable additive manufacturing of complex geometries

- Provide excellent bonding strength for diamond tools

- Are biocompatible for medical implants

- Have controlled expansion characteristics

- Can be recycled and reused in powder metallurgy

Limitations

Some drawbacks associated with these powders are:

- Expensive compared to iron or copper powders

- Sensitive to oxygen contamination during handling

- Prone to developing surface cracks if overheated

- Difficult to process by cold compaction and sintering

- Require controlled atmospheres during thermal spraying

- Lower electrical and thermal conductivity versus copper

Proper powder handling, storage and processing methods must be used to minimize limitations.

FAQs

Q: Are nickel powders hazardous?

A: Inhalation over long periods may cause respiratory sensitization. Proper PPE like masks and gloves should be worn while handling.

Q: What is the shelf life of nickel powders?

A: If stored under inert atmosphere in sealed containers, the shelf life can exceed 5 years. Oxygen and moisture absorption degrades quality over time.

Q: What particle size is best for thermal spraying?

A: 20-45 μm offers better density and bond strength. Finer powders have lower deposition efficiency.

Q: Are these magnetic or non-magnetic?

A: Pure nickel is slightly magnetic. Most nickel alloys are non-magnetic except Nichrome and MuMetal containing iron and nickel.

Q: Can nickel alloys be 3D printed?

A: Yes, Inconel and Hastelloy grades offer excellent properties but require optimized parameters for laser melting/sintering.