Overview

Nickel aluminium alloy powder is a material composed of nickel, aluminium, and other alloying elements processed into a fine powder form. It offers properties like high strength, corrosion resistance, and thermal stability making it suitable for applications such as additive manufacturing, surface coating, welding, and more.

Some key details about nickel aluminium alloy powder:

- Composition – Primarily nickel and aluminium along with elements like titanium, iron, chromium etc.

- Production Process – Gas or water atomization of melted alloy

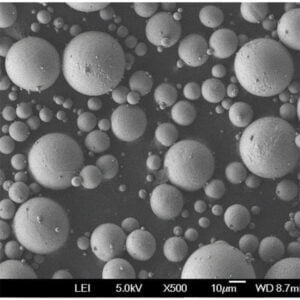

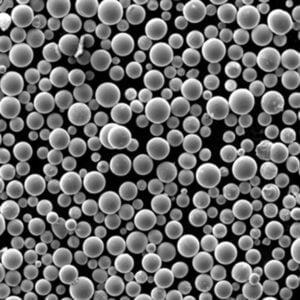

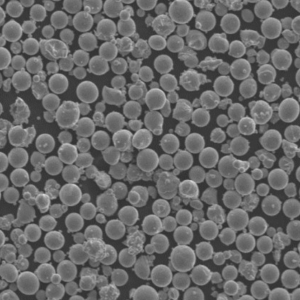

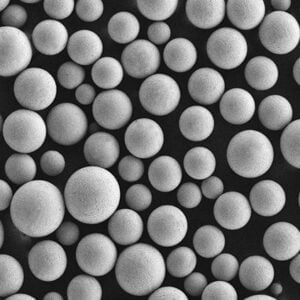

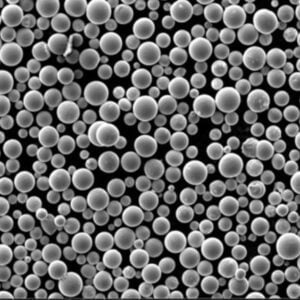

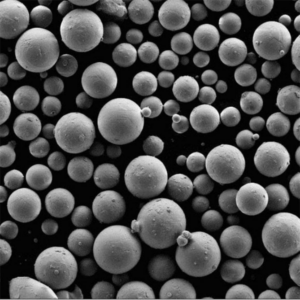

- Particle Shape – Spherical or irregular morphology

- Size Range – From 10 microns to 150 microns

- Common Trade Names – NiAl, Nichrome, Inconel, Hastelloy

Composition of Nickel Aluminium Alloy Powder

| Element | Weight % |

|---|---|

| Nickel (Ni) | 30-80% |

| Aluminium (Al) | 10-50% |

| Chromium (Cr) | 5-25% |

| Iron (Fe) | 0-20% |

| Titanium (Ti) | 0-10% |

| Cobalt (Co) | 0-5% |

| Tungsten (W) | 0-5% |

| Carbon (C) | 0-2% |

The nickel content provides corrosion resistance and thermal/structural stability at high temperatures. The aluminium improves strength and weldability. Other elements enhance specific characteristics like hardness, tensile strength etc.

Properties of Nickel Aluminium Alloy Powder

| Property | Characteristic |

|---|---|

| Density | Around 3 – 8 g/cm3 |

| Melting Point | 1000 – 1400°C |

| Thermal Conductivity | 10 – 30 W/mK |

| Electrical Resistivity | 500 – 1000 nΩ.m |

| Coefficient of Thermal Expansion | 10 – 20 μm/mK |

| Oxidation Resistance | Good, up to 1100°C |

| Corrosion Resistance | Excellent in various mediums |

| Magnetic Permeability | Very Low |

The key properties making nickel aluminium alloys useful include high strength at elevated temperatures, good corrosion and oxidation resistance, excellent thermal conductivity and low expansion, and non-magnetic behavior.

Characteristics of Nickel Aluminium Alloy Powder

Particle Morphology

- Spherical, irregular and dendritic particles

- Satellite particles may be present

- Porous surface structure

Particle Size Distribution

- Available from 10 microns to 150 microns

- Common size grades -15-45 μm, 45-106 μm etc.

- Narrow distribution ensures uniform properties

Flow Properties

- Generally free flowing powders

- Some variations between spherical and irregular particles

- Carr’s index between 15-25%

Packaging

- Containers – plastic jars/bottles, foil pouches

- Packed under argon or nitrogen atmosphere

- Moisture content <0.5%

Controlling particle shape, size distribution, flow properties and minimizing porosity/satellites allows reliable processing and performance. Proper packaging maintains powder quality during handling and storage.

Applications of Nickel Aluminium Alloy Powder

| Industry | Applications |

|---|---|

| Additive Manufacturing | Laser sintering, binder jetting |

| Welding | Hardfacing, repair, wear protection |

| Surface Coating | Thermal spray, laser cladding |

| Metal Injection Molding | Aerospace, automotive components |

| Brazing | High temperature joints |

| Investment Casting | Turbine blades, marine components |

The excellent temperature resistance and processability as powder makes nickel aluminium alloys suitable for producing strong and durable parts/coatings in extreme environments across industries.

Nickel Aluminium Alloy Powder Specifications

| Specification | Details |

|---|---|

| Available Grades | IN718, IN625, HX, Haynes 214, Haynes 242 |

| Particle Size Distribution | -325 mesh, -100 mesh +325 mesh etc |

| Particle Morphology | Predominantly spherical |

| Loose Apparent Density | Around 2-5 g/cm3 |

| Tap Density | Around 4-7 g/cm3 |

| True Density | Around 7-9 g/cm3 |

| Custom Alloy Powders | On request |

Nickel alloy powder can be customized in composition, particle characteristics, size distribution as per application requirements. Standard grades are readily available.

Suppliers and Pricing

| Supplier | Pricing Estimate |

|---|---|

| Sandvik | $50-150 per kg |

| Carpenter Powder Products | $40-250 per kg |

| Hoganas | $60-220 per kg |

| Rio Tinto Metal Powders | $80-350 per kg |

| CNPC Powder Group | $35-125 per kg |

Pricing varies based on alloy grade, particle size distribution, order quantity and purity. Customization also impacts costs. Large multinational corporations and Chinese manufacturers offer standard & custom nickel alloy powders.

Pros and Cons of Nickel Aluminium Alloy Powder

| Advantages | Disadvantages |

|---|---|

| Excellent high temperature strength | High material costs |

| Good corrosion resistance | Limited formability in some alloys |

| High hardness and wear resistance | Requires controlled atmosphere processing |

| Lightweight compared to alternatives | Susceptible to precipitation hardening |

| Customizable with alloying additions | Difficult recycling and reuse |

Nickel aluminium powders enable lightweight and durable metallic parts but require expertise in specialized powder processing methods. Composition can be tailored for an application.

Comparison of Nickel Aluminium Powder with Alternatives

| Property | Nickel Aluminium Alloy | Stainless Steel | Titanium Alloy |

|---|---|---|---|

| Density | Low | Higher | Medium |

| Cost | Medium | Low | High |

| Maximum Use Temperature | 1100°C | 850°C | 600°C |

| Corrosion Resistance | Excellent | Good | Excellent |

| Thermal Conductivity | High | Medium | Low |

| Lead Time | Medium | Low | High |

Nickel aluminium powders provide the best balance of temperature capability, corrosion resistance and cost for most applications. Stainless steel powders are cheaper but cannot operate at extreme temperatures. Titanium alloy powders are costlier but offer lower working temperatures.

FAQ

Q: What is nickel aluminium alloy powder used for?

A: Nickel aluminium alloy powder has applications in additive manufacturing, thermal spraying, welding, surface coating, investment casting etc to produce components with excellent high temperature strength, hardness and corrosion resistance.

Q: Is nickel aluminium alloy powder magnetic?

A: No, nickel aluminium alloys have very low magnetic permeability and are considered non-magnetic, unlike ferritic alloys. This provides advantages for certain applications.

Q: What is the composition of nickel aluminium alloy powder?

A: These powders contain 30-80% nickel balanced with 10-50% aluminium and alloyed with elements like chromium, iron, titanium etc based on the required properties.

Q: What particle sizes are available for this powder?

A: Nickel aluminium alloy powders range from around 10 microns to 150 microns. Some common size cuts are -325 mesh (<45 microns), -100/+325 mesh (45-150 microns) etc.

Q: Is nickel aluminium alloy environmentally friendly?

A: While nickel itself is toxic if ingested, aluminium and its alloys are considered environment-friendly materials compared to alternatives, with no hazards in their solid form. Reuse and recycling can minimize environmental impact.