ニッケル合金C276粉末

ニッケル合金C276粉末は、ハステロイC276粉末としても知られ、高耐食性を有するニッケル-モリブデン-クロム合金粉末です。幅広い腐食環境、特に酸化や塩化物イオン応力腐食割れに対して優れた耐性を有しています。

低いMOQ

さまざまなニーズに対応するため、最低注文数量を少なくしています。

OEM & ODM

顧客独自のニーズに応えるため、カスタマイズされた製品とデザインサービスを提供する。

十分な在庫

迅速な注文処理と、信頼できる効率的なサービスの提供。

顧客満足度

顧客満足を核とした高品質の製品を提供する。

この商品を共有する

目次

概要

ニッケル合金C276粉末は、ハステロイC276粉末としても知られ、高耐食性を有するニッケル-モリブデン-クロム合金粉末です。幅広い腐食環境、特に酸化や塩化物イオン応力腐食割れに対して優れた耐性を有しています。

Some key properties and characteristics of Nickel Alloy C276 powder include:

Nickel Alloy C276 Powder Key Properties

| 構成 | Nickel (Balance), Molybdenum (15-17%), Chromium (14.5-16.5%), Iron (4-7%), Tungsten (3-4.5%) |

| 密度 | 8.89 g/cm3 |

| 融点 | 1390°C (2530°F) |

| 熱伝導率 | 11 W/m-K |

| 電気抵抗率 | 1.24 microhm-cm |

| 耐酸化性 | Excellent up to 1095°C |

| 耐食性 | Extremely high in wide range of environments |

| Key Attributes | High strength, good fabricability, outstanding corrosion resistance |

Nickel Alloy C276 powder can be used to manufacture parts using additive manufacturing techniques like selective laser sintering (SLS), direct metal laser sintering (DMLS), laser powder bed fusion (L-PBF) and binder jetting. This allows complex geometries to be created with very good mechanical properties.

Some of the key applications and uses of Nickel Alloy C276 powder include:

Applications of Nickel Alloy C276 Powder

| Oil & Gas Industry | Wellhead valves, Christmas trees, flowlines, subsea components |

| 化学工業 | Pumps, valves, reaction vessels, heat exchangers |

| 公害防止 | Scrubbers, precipitators, stacks, ducts, fans |

| Pharmaceutical Industry | Reactor vessels, containers, valves, pipework |

| 食品加工業 | Tanks, valves, pipework, conveyors, nuts and bolts |

| マリンアプリケーション | Propeller shafts, corrosion-resistant fasteners, water-cooled exhaust manifolds |

| 航空宇宙産業 | Engine mounts, exhaust nozzle guides, thrust reverser systems, nacelle components |

構成

The typical composition of Nickel Alloy C276 powder is:

Typical Composition of Nickel Alloy C276 Powder

| エレメント | 重量 % |

|---|---|

| ニッケル(Ni) | バランス |

| モリブデン (Mo) | 15-17% |

| クロム(Cr) | 14.5-16.5% |

| 鉄(Fe) | 4-7% |

| タングステン(W) | 3-4.5% |

| マンガン (Mn) | 最大1% |

| ケイ素 (Si) | 最大0.5% |

| リン (P) | 0.02%最大 |

| 硫黄(S) | 0.03%最大 |

| カーボン(C) | 0.01%以下 |

The high nickel and molybdenum content gives Nickel Alloy C276 excellent corrosion resistance. The chromium helps provide oxidation resistance. Trace elements like manganese, silicon, phosphorus and sulfur are minimized as they can negatively impact corrosion resistance if present in higher amounts. The low carbon content minimizes carbide precipitation.

特性と特徴

Nickel Alloy C276 powder has the following key properties and characteristics:

Properties of Nickel Alloy C276 Powder

| 密度 | 8.89 g/cm3 |

| 溶解範囲 | 1315-1390°C (2400-2530°F) |

| 熱伝導率 | 11 W/m-K (~64 Btu-in/ft2-h-°F) |

| 電気抵抗率 | 1.24 microhm-cm at 20°C |

| 弾性係数 | 205 GPa |

| ポアソン比 | 0.29 |

| 引張強度 | 515-750 MPa (75-110 ksi) |

| 降伏強さ(0.2%オフセット) | 205-515 MPa (30-75 ksi) |

| 伸び | 25-45% |

| 硬度 | 25-35 HRC |

| 耐酸化性 | Resistant up to 1095°C |

| 熱膨張係数 | 13 μm/m-°C |

| 熱処理 | Solution treated and rapid quenched |

Some key features and advantages of Nickel Alloy C276 powder include:

- Extremely high corrosion resistance especially to pitting and crevice corrosion

- Excellent resistance to oxidation and other high temperature effects up to ~1100°C

- High strength from ambient up to elevated temperatures

- 従来の溶接方法による良好な溶接性

- Good formability allowing a range of fabrication options

- Higher strength compared to other nickel alloys

- Lower carbon content improves corrosion resistance

仕様

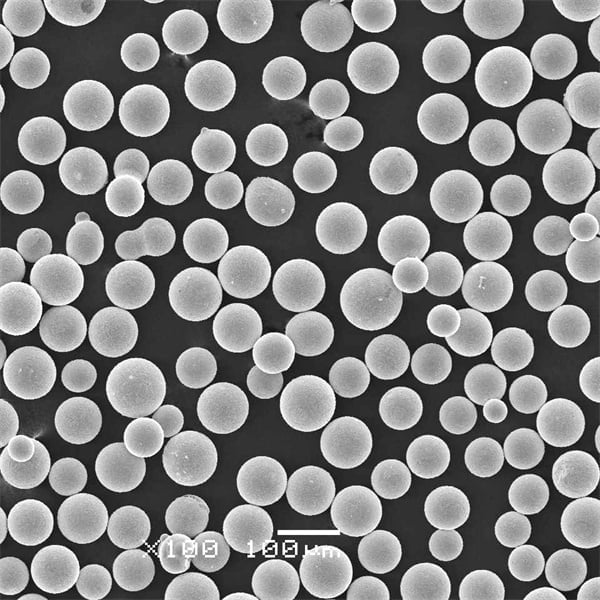

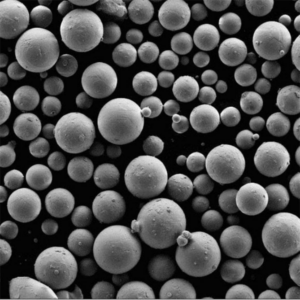

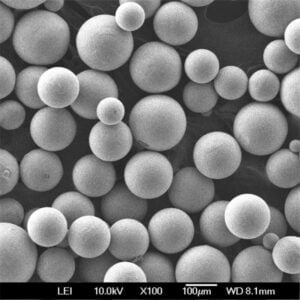

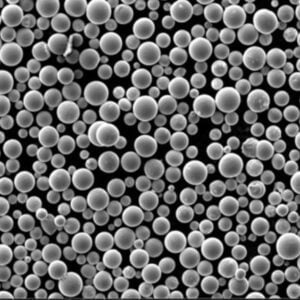

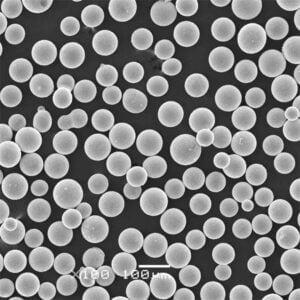

Nickel Alloy C276 powder is available in various size ranges depending on the application and manufacturing process to be used. Some typical size specifications include:

Typical Size Specifications of Nickel Alloy C276 Powder

| 粒子径 | 15-45 μm |

| 見かけ密度 | ~2.5 g/cm3 |

| 流量 | ~25 s/50g |

| サイズ分布 | D10: 20 μm; D50: 35 μm; D90: 40 μm |

Larger powder sizes may be available up to 140 mesh size (~100 μm). Smaller powder is also produced down to nano powder size (~50 nm) for advanced applications.

Various national and international specifications apply to Nickel Alloy C276 powder based on composition, condition and testing:

- AMS 5874 – Wrought Nickel Alloy C276 for General Purposes

- ASME SB-574 – Wrought Nickel Alloy C276 for Pressure Vessels

- ASTM B575 – Standard Specification for Low-Carbon Nickel Alloy Plate, Sheet, and Strip

- ISO 15156/NACE MR0175/MR0103 – Petroleum and natural gas industries

サプライヤーと価格

Some leading global suppliers of Nickel Alloy C276 powder include:

Key Suppliers of Nickel Alloy C276 Powder

| サプライヤー | 所在地 |

|---|---|

| サンドビック | スウェーデン |

| プラクセア | アメリカ |

| カーペンター・テクノロジー | アメリカ |

| ホーガナス | スウェーデン |

| LPWテクノロジー | 英国 |

| TLSテクニーク | ドイツ |

Nickel Alloy C276 powder is more expensive than nickel-based superalloys due to the high molybdenum content. Cost also depends significantly on order volume and particle size distribution. Some approximate powder pricing is:

- Small volumes (<100 kg) – $100-150 per kg

- Large volumes (>1,000 kg) – $50-90 per kg

How to Choose Nickel Alloy C276 Powder

There are a few key factors to consider when selecting Nickel Alloy C276 powder:

Key Selection Criteria for Nickel Alloy C276 Powder

| パラメータ | 詳細 |

|---|---|

| 製造工程 | Match powder size and shape to requirements of additive or other process |

| Part Properties | Strength, corrosion resistance, high temperature resistance needs |

| Operating Conditions | Temperature, pressure, media to confirm adequate performance |

| 業界標準 | Compliance for applications in oil & gas, chemical, food processing etc |

| 部品形状 | Complexity, surface finish, precision requirements |

| 試験と認証 | Confirm composition, lack of contamination, lot test reports |

| 価格 | Balance performance needs with budget constraints |

It is critical to start by understanding the application, operating conditions and properties needed. The manufacturing process determines suitable powder characteristics like particle size distribution, morphology and flowability. Chemical composition should be confirmed with the supplier’s certificate of analysis. Sample testing can validate key properties before full-scale production.

アプリケーションとユースケース

Nickel Alloy C276 finds widespread use in demanding heat and corrosion environments across various industries:

Industries and Applications for Nickel Alloy C276 Powder

| 産業 | Components and Parts |

|---|---|

| 石油・ガス | Wellhead valves, subsea flowlines, connectors, offshore rigs |

| 石油化学 | Heat exchangers, condensers, process vessels |

| マリン | Shafts, propellers, fasteners, exhaust components |

| 公害防止 | Scrubber internals, fans, ducts, stacks |

| 食品加工 | Tanks, pipework, valves, nuts/bolts |

具体的な応用例としては、以下のようなものがある:

- Oil platforms – Seawater lift pumps, piping systems, wellhead Christmas trees, subsea components like connectors, flowlines, jumpers etc.

- Petrochemical plants – Heat exchanger tubing, condenser tubes, process vessels and tanks, pipes and valves carrying corrosive media

- Marine vessels – Components like propeller shafts, water-cooled exhaust manifolds, corrosion-resistant fasteners

- Desalination – Intake screens, high pressure pump components and plungers, reverse osmosis membrane housings

- Pollution control systems – FGD and SCR system internals like fans, ducts, stacks, scrubber liners exposed to acidic gases or seawater

- Food/beverage processing – Pipework, process vessels and tanks, nuts/bolts, valves carrying acidic foods

Some typical components manufactured in Nickel Alloy C276 powder include:

Typical Components Using Nickel Alloy C276 Powder

| コンポーネント | Descriptions |

|---|---|

| パンプス | Centrifugal, positive displacement pumps for corrosive liquids |

| Impellers | For process handling highly acidic or saline solutions |

| バルブ | Gate, ball, butterfly, globe valves in piping systems |

| ノズル | Spray nozzles for pollution control scrubbers |

| Reaction Vessels | For chemical synthesis reactors under high temperature and pressure |

| Heat Exchanger Tubes | Straight tubes or complex serpentine geometries |

| Pipe Fittings | Elbows, tees, reducers conveying various corrosive media |

Nickel Alloy C276 Powder vs Alternatives

Nickel Alloy C276 is compared below with key alternative nickel and stainless-steel alloys:

Comparison of Nickel Alloy C276 Powder with Alternatives

| 合金 | 耐食性 | 耐熱温度 | コスト | 製作 |

|---|---|---|---|---|

| Nickel Alloy C276 | 極めて高い | Excellent to 1100°C | 高い | Good machinability/weldability |

| Alloy C22 | 非常に良い | Very Good to ~1200°C | 高い | Weldable |

| アロイ625 | 高い | 1000℃まで良好 | ミディアム | 簡単な加工 |

| 316/316L Stainless Steel | 中程度 | Fair up to 300°C | 低い | Most readily fabricated |

| Duplex Stainless | 素晴らしい | Limited to 250°C | 低い | More difficult fabrication |

Nickel Alloy C276 provides the best corrosion resistance across a wide range of aggressive environments compared to alternatives. It can reliably perform at high operating temperatures exceeding 1000°C. These benefits do come at a higher cost due to its specialized composition rich in strategic alloys. However, its ease of fabrication using standard methods provides a cost advantage over other more complex, proprietary alloys.

Limitations of Nickel Alloy C276

Despite its high performance, Nickel Alloy C276 does have some limitations to consider:

Limitations of Nickel Alloy C276 Powder

| 制限 | 説明 |

|---|---|

| コスト | More expensive than stainless steels due to nickel and molybdenum content |

| 製作 | Heavier sections over 50mm can show lower corrosion resistance |

| セクションの厚さ | Maximum recommended section is 25mm for optimum performance |

| Thermal Processing | Special control of heating/cooling cycles needed to avoid impairing properties |

Thinner sections up to 25mm maintain consistently high corrosion resistance throughout. Care must also be taken to properly solution treat and quench finished parts to achieve full corrosion resistance without precipitation of deleterious phases. Overall though, Nickel Alloy C276 is engineered to be quite forgiving to fabricate relative to other highly alloyed materials.

よくあるご質問

FAQ about Nickel Alloy C276 Powder

| 質問 | 答え |

|---|---|

| What industries use Nickel Alloy C276? | Petrochemical, oil & gas, marine applications, chemical processing, pollution control, desalination |

| Why is C276 better than stainless steel? | Far higher corrosion resistance, performs well at much higher temperatures |

| What is Nickel Alloy C276 used for? | Pipes, valves, pumps, heat exchangers, fasteners – wetted parts in contact with aggressive chemicals/fluids |

| What is the corrosion resistance of C276? | Extremely high resistance to pitting, crevice corrosion, stress corrosion cracking across range of acids, chlorides etc |

| Can you weld Nickel Alloy C276? | Yes, C276 offers excellent weldability using a range of welding processes |

| What alloy is similar to C276? | Alloy C22 offers comparable corrosion resistance but lower fabricability |

| Is Hastelloy C276 expensive? | Yes, it costs more than stainless steel due to nickel/molybdenum but offers superior performance |

| Is Nickel Alloy C276 compatible with seawater? | Yes, it has excellent resistance to saline environments making it ideal for marine applications |

結論

Nickel Alloy C276 powder provides outstanding corrosion and temperature resistance coupled with good fabrication characteristics. This makes it an excellent choice for manufacturing critical parts and components exposed to aggressive operating environments across oil & gas, chemical processing and other industries. It does come at a premium cost but offers long, reliable service life with lower maintenance demands compared to other alloys. With additive manufacturing, it enables high complexity parts with properties equaling or exceeding tradition manufacturing. For extreme chemical corrosion or high temperatures approaching 1100°C, Nickel Alloy C276 is an ideal alloy system.