概要 ニオブ合金粉末

ニオブ合金粉末とは、ニオブを主成分とする合金の粉末冶金形態を指す。コロンビウムとしても知られるニオブは、記号Nb、原子番号41の耐火性遷移金属である。融点が高く、高温での強度が高く、耐食性に優れている。

ニオブ合金は、ジェットエンジン、ロケット、ガスタービン、原子炉、熱交換器などの耐熱性を必要とする用途に、ニオブのこれらの望ましい特性を活用します。合金元素の添加により、純ニオブよりも高温強度、耐クリープ性、耐酸化性などが強化されたニオブ合金が生まれます。

一般的に使用されるニオブ合金には、Nb-Ti合金、Nb-Zr合金、Nb-Mo合金、Nb-Hf合金などがある。合金粉末は粉末冶金技術を使って特注の部品形状に圧縮することができます。これにより、複雑な形状を正味の形状に近い形で形成することができ、材料の無駄を最小限に抑えることができます。使用される方法には、プレス焼結、金属射出成形、熱間静水圧プレス、積層造形などがある。

世界のニオブ合金粉末市場は20xx年に$xx万と推定され、20xx年には$xx万に達すると予測され、予測期間中のCAGRはxx%で成長する。主な促進要因は、航空宇宙エンジンでの使用増加、石油・ガス産業での採用拡大、医療機器での使用拡大である。

ニオブ合金粉末の種類

| 合金 | エレメント | 主要物件 | 一般的な用途 |

|---|---|---|---|

| ニオブチタン(Nb-Ti) | ニオブ+チタン | 耐食性、低温および高温での強度 | 原子炉、熱交換器、超伝導マグネット |

| ニオブ・モリブデン(Nb-Mo) | ニオブ+モリブデン | 高温強度、耐クリープ性 | 航空機エンジン、ロケット・サブアセンブリ |

| ニオブ-ジルコニウム(Nb-Zr) | ニオブ+ジルコニウム | 良好な耐酸化性、適度な延性 | 工業用発熱体、ガラス加工機器 |

| ニオブ-ハフニウム(Nb-Hf) | ニオブ+ハフニウム | 優れた高温特性 | ロケットノズル、タービンブレード、核燃料被覆管 |

ニオブ合金粉末の特性

| プロパティ | 説明 | Benefit in Applications |

|---|---|---|

| 高融点 | Niobium alloys boast exceptional melting points, typically exceeding 2400°C. This property makes them ideal for applications exposed to extreme temperatures, such as jet engine components, rocket nozzles, and furnace liners. | Enables components to maintain structural integrity and resist melting even under intense heat, ensuring safe and reliable operation in high-temperature environments. |

| Superior High-Temperature Strength | Niobium alloys retain remarkable strength at elevated temperatures. Unlike many materials that weaken considerably as they heat up, niobium alloys exhibit minimal degradation in strength, making them crucial for hot sections of engines and other high-temperature machinery. | Allows components to withstand significant mechanical loads at high temperatures, preventing failures and extending service life in demanding applications. |

| Favorable Strength-to-Weight Ratio | Compared to other high-temperature materials, niobium alloys offer a superior balance between strength and weight. This translates to lighter components without compromising performance, a critical factor in aerospace and other weight-sensitive industries. | Reduces overall weight of components, leading to improved fuel efficiency in aircraft and increased payload capacity in rockets. |

| 優れた耐酸化性 | Niobium alloys demonstrate exceptional resistance to oxidation, a process where a material reacts with oxygen at high temperatures, forming a brittle and non-protective layer. This resistance allows components to maintain their integrity and functionality in environments with high oxygen content. | Protects components from degradation and premature failure due to oxidation, ensuring longer service life and reliable performance. |

| アロイ化によって調整可能な特性 | The properties of niobium alloys can be significantly modified by incorporating various alloying elements. Strategic additions can enhance specific characteristics like strength, ductility, or creep resistance, allowing for the creation of customized alloys for specific applications. | Provides engineers with a wider range of material options to meet the specific needs of demanding applications. |

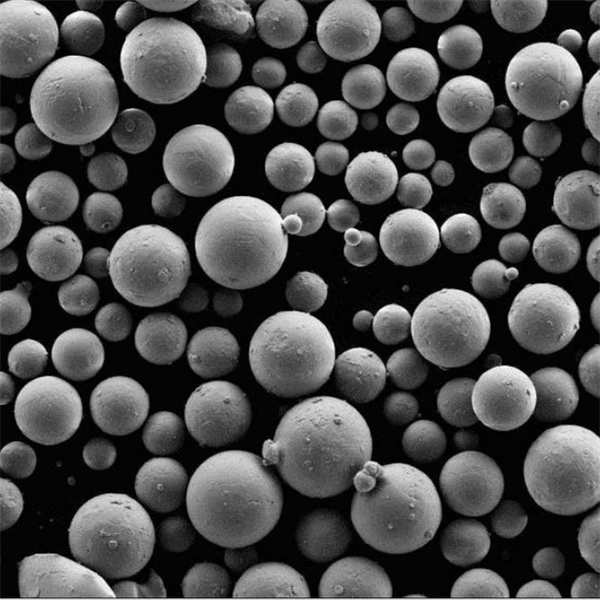

| 粉体の特徴 | Niobium alloy powders are available in various particle sizes, morphologies (shapes), and flowabilities. These characteristics significantly impact the additive manufacturing (AM) process and the final properties of the printed parts. | Allows for optimization of the AM process for specific applications and control over the microstructure and mechanical properties of the final component. |

| 生体適合性 | Certain niobium alloys exhibit good biocompatibility, meaning they are well-tolerated by the human body. This property makes them suitable for biomedical applications like implants and surgical devices. | Offers potential for the development of implants that integrate well with bone tissue, reducing the risk of rejection and improving patient outcomes. |

| Superconductivity at Cryogenic Temperatures | Some niobium alloys exhibit superconductivity, a phenomenon where electrical resistance vanishes entirely at extremely low temperatures. This property makes them crucial for superconducting magnets used in medical imaging (MRI machines) and scientific research. | Enables the creation of powerful magnets with minimal energy loss, contributing to advancements in medical diagnostics and scientific discovery. |

ニオブ合金粉末の特徴

| 特徴 | 説明 | Benefit in Applications |

|---|---|---|

| High Strength & Ductility | Niobium alloys powder offers exceptional strength-to-weight ratio. Even after deformation, the material retains its ability to absorb stress without breaking. | This allows for the creation of lightweight components in aerospace (e.g., aircraft turbine blades) and automotive sectors (e.g., high-performance engine parts) that can withstand significant mechanical loads. |

| Superior Heat Resistance | Niobium boasts a very high melting point, and its alloys maintain exceptional strength at elevated temperatures. | This makes niobium alloys powder ideal for applications exposed to extreme heat, such as jet engine components, nuclear reactors, and high-temperature furnace parts. They can retain their structural integrity and resist deformation even under harsh thermal conditions. |

| Enhanced Corrosion Resistance | Niobium forms a strong, protective oxide layer when exposed to air, offering excellent resistance to corrosion across various environments. | This characteristic makes niobium alloys powder valuable for applications in marine environments (e.g., ship hulls, offshore oil rigs) and chemical processing plants where components are exposed to corrosive substances. |

| オーダーメイド物件 | By adjusting the composition of the alloy powder and the manufacturing process, properties like strength, ductility, and workability can be fine-tuned for specific applications. | This versatility allows engineers to create custom-designed components with the optimal combination of properties required for their specific function. |

| Excellent Biocompatibility | Certain niobium alloys exhibit exceptional biocompatibility, meaning they are well-tolerated by the human body. | This characteristic makes niobium alloys powder a promising material for medical implants, such as bone screws, dental prosthetics, and heart valves. The biocompatibility minimizes the risk of rejection and ensures long-term functionality of the implant. |

| Superconductivity (at Cryogenic Temperatures) | Some niobium alloys demonstrate superconductivity, the ability to conduct electricity with zero resistance, at extremely low temperatures. | This property has significant applications in the field of medical imaging (MRI machines) and scientific research involving high-powered magnets. |

| 積層造形の互換性 | Niobium alloy powders are well-suited for additive manufacturing techniques like 3D printing. The powdered form allows for precise layering and creation of complex geometries. | This compatibility opens doors for the production of intricate, high-performance components with minimal material waste. It allows for lighter and more efficient designs in various industries. |

| Fine Particle Size & Distribution | Niobium alloy powders can be manufactured with a controlled particle size and distribution. This characteristic influences flowability, packing density, and printability in additive manufacturing. | Precise control over particle size allows for optimized powder behavior during the manufacturing process, leading to the creation of high-quality, consistent end products. |

| 酸化ポテンシャル | Niobium readily forms an oxide layer when exposed to air or moisture. While this layer offers corrosion resistance, it can affect the electrical conductivity and surface properties of the material. | Careful storage and handling are crucial to minimize oxidation and ensure the desired properties of the niobium alloy powder are preserved. In some applications, surface treatments may be necessary to control the oxide layer formation. |

の応用 ニオブ合金粉末

| 産業 | 申し込み | レバレッジ物件 | メリット |

|---|---|---|---|

| 航空宇宙 | Aircraft Engine Components (Turbine Blades, Discs) Rocket Engine Nozzles Airframe Structures |

High Strength-to-Weight Ratio, Excellent High-Temperature Performance, Oxidation Resistance | Enables significant weight reduction in critical components, improving fuel efficiency and range. Offers exceptional resistance to extreme temperatures and exhaust gas pressures. Provides superior structural integrity under demanding flight loads. |

| エレクトロニクス | High-Performance Capacitors (Tantalum Electrolytic Capacitors) Superconducting Magnets (Medical Imaging Equipment, Particle Accelerators) |

High Electrical Conductivity, Superconductivity at Low Temperatures | Delivers exceptional capacitance and long lifespans in electronic devices. Allows for the creation of powerful magnets with minimal energy loss, vital for medical imaging and scientific research. |

| エネルギー | Heat Exchangers in Nuclear Reactors | High Strength, Corrosion Resistance, Neutron Transparency | Maintains structural integrity under high pressure and temperature within reactors. Excellent resistance to corrosion from coolants and nuclear byproducts. Allows for efficient neutron passage, crucial for nuclear fission reactions. |

| 化学処理 | Reactors for Aggressive Chemical Environments | Corrosion Resistance, High Melting Point | Enables the safe and efficient handling of highly corrosive chemicals at elevated temperatures. |

| バイオメディカル | Prosthetic Implants (Knee, Hip Replacements) | Biocompatibility, Strength, Corrosion Resistance | Offers excellent compatibility with human tissue, minimizing rejection risks. Provides exceptional strength and durability for long-lasting implant performance. Resists corrosion from bodily fluids, ensuring implant longevity. |

| 切削工具 | High-Speed Machining Tools | High Hardness, Wear Resistance, Heat Resistance | Enables high cutting speeds and extended tool life, improving machining efficiency. Offers superior resistance to wear and tear during demanding machining operations. Maintains cutting edge integrity at elevated temperatures. |

仕様と規格

ニオブ合金粉末は、様々な用途の要求をターゲットとした様々な仕様で入手可能です:

| プロパティ | 説明 | Standards (Reference) |

|---|---|---|

| 化学組成 | Niobium (Nb) content with specific weight percentages of alloying elements (e.g., Titanium (Ti), Tantalum (Ta)) | ASTM International ASTM B883 [ASTM B883], MPIF Standard 35 [MPIF 35] |

| 純度 | Minimum weight percentage of Niobium (Nb) in the powder, typically exceeding 99% | ASTM International ASTM B883 [ASTM B883], MPIF Standard 35 [MPIF 35] |

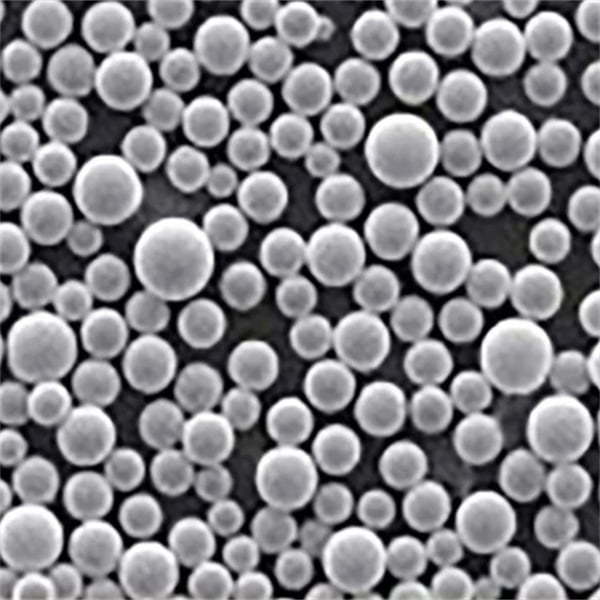

| 粒度分布 | Range and/or average particle size in micrometers (μm) or mesh size. Can be categorized as coarse, medium, or fine powders | ASTM International ASTM B883 [ASTM B883], MPIF Standard 35 [MPIF 35] |

| 粒子の形態学 | Shape of the powder particles, such as spherical, angular, or irregular | No specific standard, typically vendor specification |

| 見かけ密度 | Density of the powder in its loosely packed state (g/cm³). Influences powder handling and flowability | ASTM International ASTM B212 [ASTM B212], MPIF Standard 42 [MPIF 42] |

| タップ密度 | Density of the powder after a standardized tapping routine (g/cm³). Provides a higher value than apparent density and indicates packing efficiency | ASTM International ASTM B212 [ASTM B212], MPIF Standard 42 [MPIF 42] |

| 流動性 | Ease with which the powder flows under gravity. Measured using standardized tests or by vendor specifications | ASTM International ASTM B213 [ASTM B213], MPIF Standard 15 [MPIF 15] |

| 酸素含有量 | Weight percentage of oxygen (O₂) present in the powder. Affects the mechanical properties of final products | ASTM International ASTM E1019 [ASTM E1019] |

| 窒素含有量 | Weight percentage of nitrogen (N₂) present in the powder. High nitrogen content can be detrimental to some applications | ASTM International ASTM E1019 [ASTM E1019] |

| Interstitial Impurities | Weight percentages of other elements like Carbon (C), Iron (Fe), or other metallic impurities | ASTM International ASTM E1019 [ASTM E1019] |

サプライヤーと価格

ニオブ合金粉末の世界的な大手サプライヤーには以下のようなものがある:

| サプライヤー | 商品説明 | 純度 | 粒子径 | Price (per kg) | Minimum Order | アプリケーション |

|---|---|---|---|---|---|---|

| MSE Supplies | MSE PRO 99.5% Niobium (Nb) Micron Powder | 99.5% Nb | 3 microns | $579.95 | 1 kg | High-temperature parts, alloys, spray coating, filters, and corrosion-resistant applications |

| アトランティック・エクイップメント・エンジニア | Niobium Metal Powder (irregular or spherical shaped) | 99.8% Nb | 1~5ミクロン | Request Quote | 100 grams | Strengthening alloys, superconductivity |

| Goodfellow | ニオブ粉 | 99.85% Nb | Up to 45 microns | $1,067.96 – $1,443.19 | 10 grams | Superalloys, welding products, superconducting magnets, improving strength and corrosion resistance in steel and nickel alloys |

| スタンフォード アドバンスト マテリアルズ | NB0067 Niobium Powder | Not specified | Not specified | Request Quote | Not specified | Additives for alloys, welding rods, and refractory materials |

| ChemDirect | Nb-598 Technical Grade Niobium Powder | ≥ 98% Nb | Not specified | $564.40 (100mg) | 100 milligrams | Superalloys, nuclear reactors, aerospace, and chemical processing |

| シグマ・アルドリッチ | Niobium-Tin Alloy (Nb75Sn25) Powder | Not specified | Not specified | $578.00 | Not specified | Superconductors |

の長所と短所 ニオブ合金粉末

| 特徴 | 長所 | 短所 |

|---|---|---|

| 強度と耐久性 | Unmatched tensile strength and resistance to deformation at high temperatures Ideal for components enduring extreme stress, like jet engine parts and superconductor housings |

Can be more challenging to machine compared to some other alloys |

| 高温性能 | Retains structural integrity even under extreme heat Enables applications in high-performance environments like aerospace and nuclear energy |

May require specialized manufacturing techniques to handle the powder’s properties |

| 耐食性 | Excellent resistance to a wide range of corrosive agents Extends the lifespan of components in harsh environments like chemical processing plants and marine applications |

Corrosion resistance can vary depending on the specific alloy composition |

| 生体適合性 | Non-toxic and compatible with human tissue Well-suited for medical implants like bone screws, joint replacements, and dental fixtures |

Limited selection of biocompatible niobium alloy powders compared to other implant materials |

| 積層造形の互換性 | Powder form makes it ideal for advanced manufacturing processes like 3D printing Allows for complex geometries and lightweight designs |

Powder characteristics can impact printability, requiring careful selection and process optimization |

| 軽量化 | Lower density than many other high-performance alloys Contributes to lighter weight components in applications like aircraft and spacecraft |

Strength-to-weight ratio may not always be the most favorable compared to certain alternatives |

| 空室状況 | Niobium is a relatively abundant element Less susceptible to supply chain disruptions compared to some rarer materials |

Processing niobium powder into usable alloys can be more energy-intensive than some other materials |

よくあるご質問

Q: ニオブ合金粉末は何に使われるのですか?

A: ニオブ合金粉末は、優れた耐熱性、1000℃までの高温での強度、耐酸化性、耐腐食性などが要求される航空宇宙、エネルギー、自動車、医療、化学工業用途の高性能部品の製造に使用されます。

Q: ニオブ合金粉末はどのようにして作られるのですか?

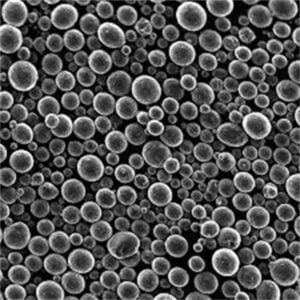

A: ガスアトマイズ法により製造され、溶融したニオブ合金混合物の流れは、アルゴンまたは窒素ガスの噴流によって微細な液滴に分解され、ミクロンサイズの粉末粒子に凝固します。この粉末は、回転電極法またはプラズマ回転電極法でも製造できる。

Q: ニオブ合金粉末の加工にはどのような技術が使われていますか?

A: 主要な粉末加工ルートは、プレス・焼結、金属射出成形、熱間静水圧プレス、そしてレーザー粉末床溶融、バインダージェッティング、指向性エネルギー堆積などの付加製造法である。これらの技術により、複雑でニアネットシェイプのニオブ部品を製造することができる。

Q: ニオブと合金になる必須元素は何ですか?

A: 最も一般的な合金添加物は、チタン、モリブデン、ジルコニウム、ハフニウム、タングステン、タンタルなどです。これらの元素は、ニオブ基合金の強度、耐クリープ性、耐酸化性、加工性などの特性を向上させます。最適な組成は用途によって異なる。

Q: ニオブ合金粉末はどのような規格に適合していますか?

A: 主な規格には、ニオブ合金の化学的限界に関するSAE AMS 5815、ニオブ金属の仕様に関するASTM B393、機械的特性、物理的特性、加工性特性に関するISO 15371、保護処理と品質試験に関するMIL-STD-2207、品質管理(ISO 9001)と環境責任(ISO 14001)に関する国際規格などがあります。