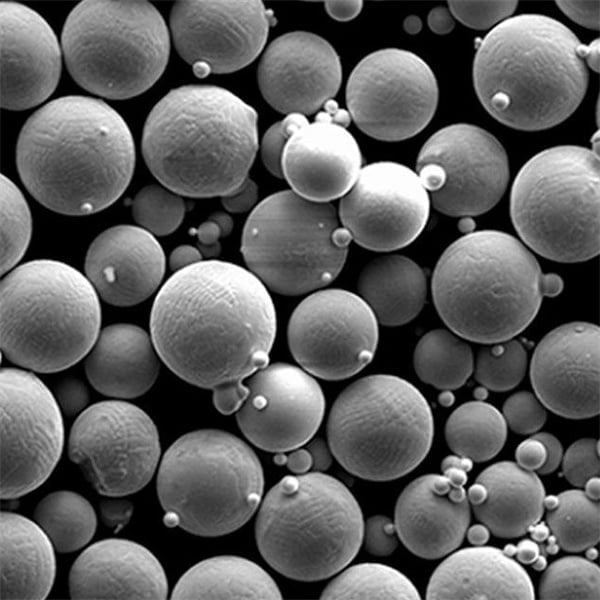

Ag18CuPパウダー

想像してみてください。あなたは重要な機械の一部を丹念に組み立てています。すべての部品がシームレスに組み合わされ、エラーの許容範囲がゼロである必要があります。しかし、このレベルの精度を達成することは、特に溶接やろう付けのような伝統的な接合方法では、悪夢となりかねません。そこでAg18CuPパウダーが活躍します。

想像してみてください。あなたは重要な機械の一部を丹念に組み立てています。すべての部品がシームレスに組み合わされ、エラーの許容範囲がゼロである必要があります。しかし、このレベルの精度を達成することは、特に溶接やろう付けのような伝統的な接合方法では、悪夢となりかねません。そこでAg18CuPパウダーが活躍します。

ティースプーン一杯のブラックホールに匹敵するほど高密度で、しかも砂のように細かい物質を想像してみてほしい。それこそが球状タングステン粉の魔法であり、航空宇宙から医療に至るまで、産業に革命をもたらしている驚異のエンジニアリングなのだ。しかし、この不思議な素材とはいったい何なのか?

Imagine you’re a manufacturer tasked with creating a super strong, heat-resistant component. You have a toolbox filled with various metal powders, but how do you seamlessly connect them? Enter BNi-2 powder, a superhero in the world of metal joining. Think of it as a superglue specifically designed for metals, and

Imagine building complex, high-strength components that are incredibly light. Imagine achieving this feat not through traditional manufacturing methods, but through a cutting-edge technology: 3D printing. This is the magic of AlSi7Mg powder, a metal powder alloy rapidly transforming the landscape of additive manufacturing. An Overview of AlSi7Mg Powder AlSi7Mg powder,

The year 2024 promises to be a pivotal year for powder metallurgy (PM), a manufacturing technique that utilizes metal powders to create complex, near-net-shape components. At the heart of this progress lies the power of the metal powders themselves. Just like the ingredients in a recipe, the specific type of

Additive manufacturing, also known as 3D printing, has revolutionized the way we design and produce complex parts. Selective laser melting (SLM) is a powerful 3D printing technique that uses a laser beam to selectively melt metal powder layer by layer, building a three-dimensional object from a digital blueprint. Choosing the

Additive manufacturing, also known as 3D printing, has revolutionized how we design and produce complex parts. Selective laser sintering (SLS) is a powerful 3D printing technique that uses a laser beam to selectively melt and fuse together metal powder particles, layer by layer, to build a three-dimensional object. The choice

Introduction to 6013 Metal Powder for MIM Metal injection molding (MIM) has revolutionized the manufacturing of complex, near-net-shape metal components. Imagine achieving intricate geometries and exceptional dimensional accuracy – all at a fraction of the cost and waste associated with traditional machining techniques. That’s the magic of MIM. But this

The world of metal manufacturing is vast and ever-evolving. But within this intricate landscape lies a process that thrives on precision and efficiency: Powder Metallurgy (PM). This technique involves transforming metal powders into intricate shapes through a series of steps like compaction and sintering. And when it comes to selecting

Have you ever dreamt of building complex metal parts with unmatched strength, resilience, and resistance to harsh environments? Well, stop dreaming and start exploring the wonders of HK30! This superhero material is taking the world of powder metallurgy by storm, offering a unique blend of properties that leave traditional alloys

Imagine this: you’re meticulously assembling a critical piece of machinery. Every component needs to fit together seamlessly, with zero tolerance for error. But achieving this level of precision can be a nightmare, especially with traditional joining methods like welding or brazing. Here’s where Ag18CuP powder swoops in, acting as your silver bullet for creating exceptionally

Imagine a material so dense it could rival a black hole in a teaspoon, yet so fine it flows like sand. That’s the magic of spherical tungsten powder, a marvel of engineering that’s revolutionizing industries from aerospace to medicine. But what exactly is this wonder material, and how does it achieve its unique properties? Buckle

Imagine you’re a manufacturer tasked with creating a super strong, heat-resistant component. You have a toolbox filled with various metal powders, but how do you seamlessly connect them? Enter BNi-2 powder, a superhero in the world of metal joining. Think of it as a superglue specifically designed for metals, and in spherical form, it offers

Imagine building complex, high-strength components that are incredibly light. Imagine achieving this feat not through traditional manufacturing methods, but through a cutting-edge technology: 3D printing. This is the magic of AlSi7Mg powder, a metal powder alloy rapidly transforming the landscape of additive manufacturing. An Overview of AlSi7Mg Powder AlSi7Mg powder, also known as Aluminum Silicon

The year 2024 promises to be a pivotal year for powder metallurgy (PM), a manufacturing technique that utilizes metal powders to create complex, near-net-shape components. At the heart of this progress lies the power of the metal powders themselves. Just like the ingredients in a recipe, the specific type of metal powder used significantly impacts

Additive manufacturing, also known as 3D printing, has revolutionized the way we design and produce complex parts. Selective laser melting (SLM) is a powerful 3D printing technique that uses a laser beam to selectively melt metal powder layer by layer, building a three-dimensional object from a digital blueprint. Choosing the right metal powder for SLM

Additive manufacturing, also known as 3D printing, has revolutionized how we design and produce complex parts. Selective laser sintering (SLS) is a powerful 3D printing technique that uses a laser beam to selectively melt and fuse together metal powder particles, layer by layer, to build a three-dimensional object. The choice of metal powder plays a

Introduction to 6013 Metal Powder for MIM Metal injection molding (MIM) has revolutionized the manufacturing of complex, near-net-shape metal components. Imagine achieving intricate geometries and exceptional dimensional accuracy – all at a fraction of the cost and waste associated with traditional machining techniques. That’s the magic of MIM. But this innovative process hinges on a

The world of metal manufacturing is vast and ever-evolving. But within this intricate landscape lies a process that thrives on precision and efficiency: Powder Metallurgy (PM). This technique involves transforming metal powders into intricate shapes through a series of steps like compaction and sintering. And when it comes to selecting the right metal powder for

Have you ever dreamt of building complex metal parts with unmatched strength, resilience, and resistance to harsh environments? Well, stop dreaming and start exploring the wonders of HK30! This superhero material is taking the world of powder metallurgy by storm, offering a unique blend of properties that leave traditional alloys in the dust. But what

3Dプリンティングと積層造形用金属粉末