ブログ

すべてのコレクション

ガスアトマイズ金属粉

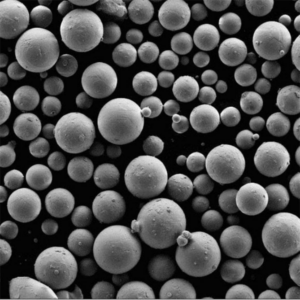

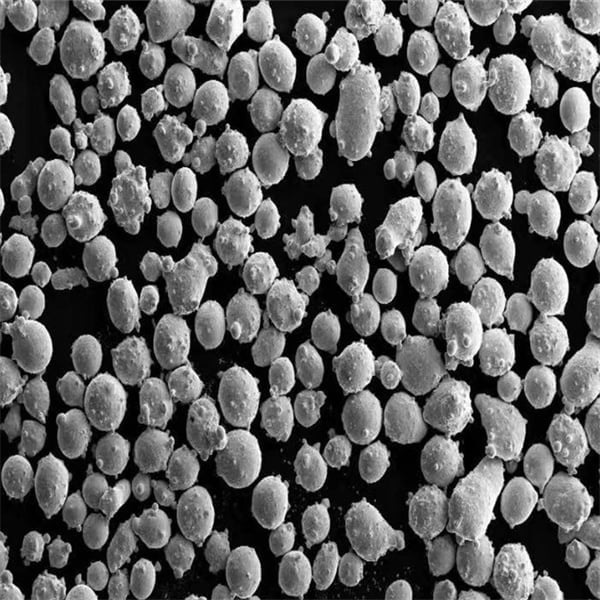

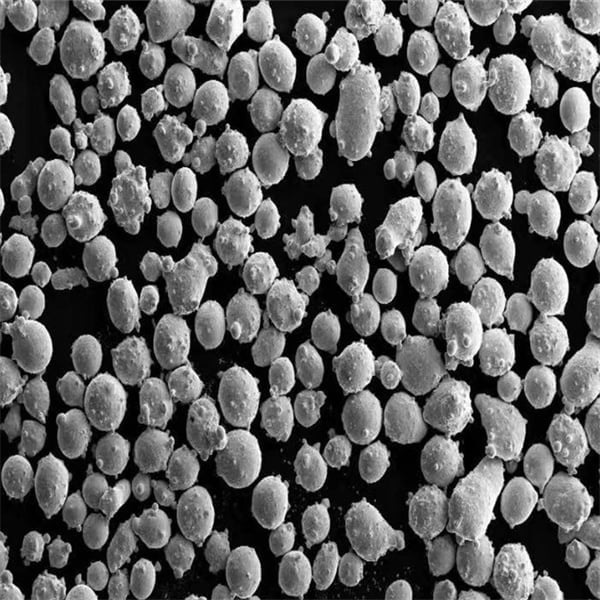

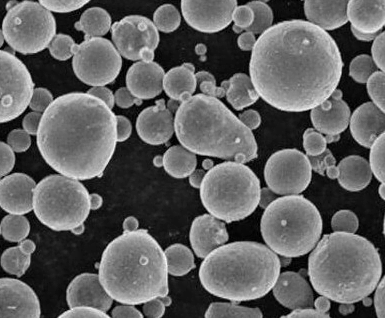

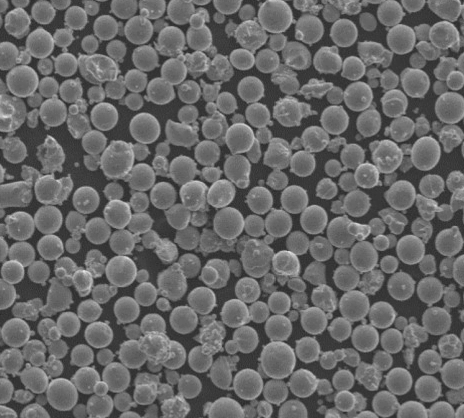

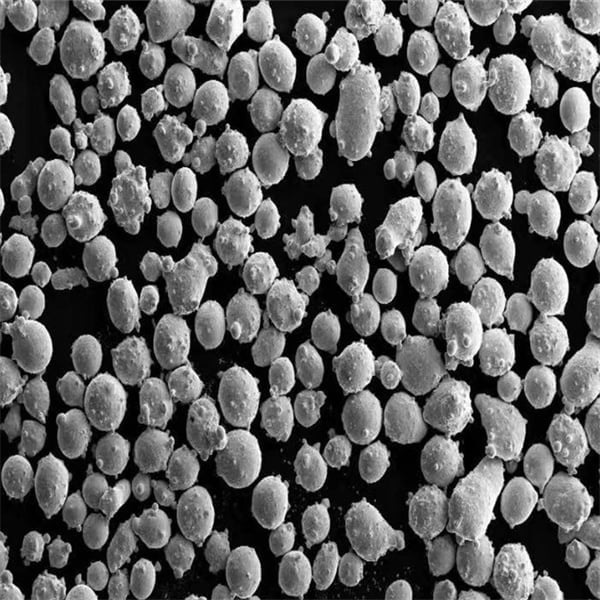

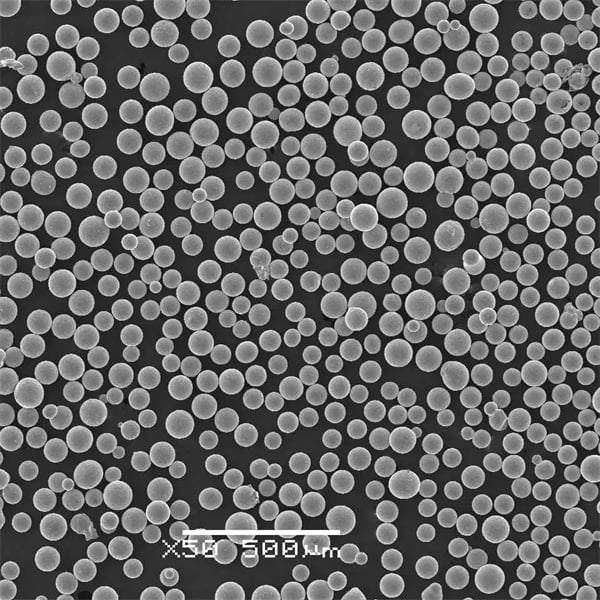

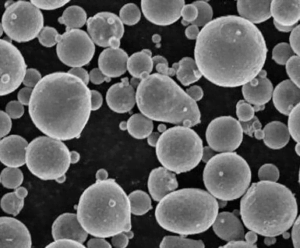

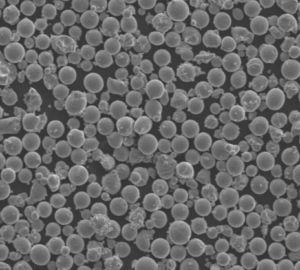

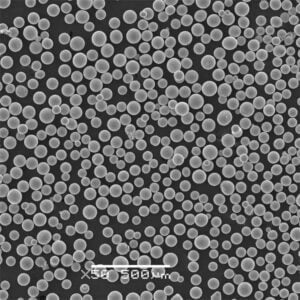

ガスアトマイズ金属粉末の概要 ガスアトマイズ金属粉末は、溶融合金原料を高速不活性ガスジェットで噴霧化することにより製造される金属微粒子材料である。これにより、積層造形、金属射出成形、その他の用途に理想的な球状形態が得られます。ガスアトマイズの特徴続きを読む

インコネル3Dプリント部品

インコネル3Dプリント部品の概要 インコネル3Dプリント部品は、積層造形(AM)法を使用してインコネル超合金粉末から製造された部品を指します。インコネル・グレードは、高強度と組み合わせた卓越した耐熱性と耐腐食性を提供し、航空宇宙、発電、およびその他の要求の厳しい用途に理想的に適しています。主な特性

チタン・アルミニウム合金

概要 チタンアルミニウム合金は、チタンとアルミニウムの混合物を含む金属材料のクラスです。軽量で強度が高く、高温での耐食性や耐酸化性に優れています。TiAl合金は、その特性から、航空宇宙および自動車用途の重要な高温構造材料とみなされている。

MIMアディティブ・マニュファクチャリング

mim additive manufacturingは、小型で複雑な金属部品を大量に生産する工業プロセスを指す。複合金属粉末原料を射出成形装置でグリーン状態の形状に成形し、脱バウンドさせた後、焼結して完全な密度を達成する。MIMは、ポリマー射出成形の幾何学的な柔軟性を利用する。

ガスアトマイズ金属粉

ガスアトマイズ金属粉末は、金属射出成形(MIM)、積層造形、プレス・焼結、溶射コーティング、粉末冶金などの用途向けに、微細な球状金属粉末を製造するための材料加工法を指します。ガスアトマイズでは、溶融金属合金を高圧不活性ガスで液滴に分解する。

タングステン金属粉

Overview of tungsten metal powder Tungsten metal powder refers to fine particulate material composed primarily of elemental tungsten for use in various industrial applications. Key properties include extremely high density, strength, hardness, and high temperature durability. Common applications of tungsten powder include: Tungsten is considered a critical raw material for its unique performance combined with

ガスアトマイズ金属粉

Overview of gas atomized metal powder Gas atomized metal powder refers to metallic particulate materials produced by atomizing molten alloy feedstock with high velocity inert gas jets. This imparts a spherical morphology ideal for additive manufacturing, metal injection molding, and other applications. Gas atomization features: Continue reading to learn about composition options, particle qualities, usage

インコネル3Dプリント部品

Overview of inconel 3d printed part Inconel 3D printed parts refer to components fabricated from Inconel superalloy powders using additive manufacturing (AM) methods. Inconel grades offer exceptional heat and corrosion resistance combined with high strength, making them ideally suited to aerospace, power generation, and other demanding applications. Key properties of Inconel 3D printed parts: Continue

高温鉄粉

Overview High temperature iron powders are specialized metallic powders made from iron-based alloys designed to operate at elevated temperatures exceeding 850°C without rapidly losing strength. Conventional iron and steel powders oxidize and deteriorate faster beyond this threshold. By carefully tailoring powder chemistry and processing treatments, high temperature strength and environmental resistance is enhanced. Key application

金属粉末製造

Overview Metal powders are fine metal particles used as feedstock for manufacturing techniques like additive manufacturing, metal injection molding, and powder metallurgy pressing and sintering. Producing advanced specialty metal powders with precise control of chemistry, particle size distribution, morphology, and microstructure is critical to properties of finished components. There are various methods used for large

チタン・アルミニウム合金

Overview Titanium Aluminum Alloys are a class of metallic materials that contain a mixture of titanium and aluminum. They are lightweight, have high strength, and excellent corrosion and oxidation resistance at high temperatures. TiAl alloys are considered an important high-temperature structural material for aerospace and automotive applications due to their unique combination of properties. Their

電子ビーム製造

Electron beam manufacturing refers to an additive manufacturing process that uses a focused beam of high-energy electrons to selectively melt and fuse metallic powder particles together layer-by-layer to directly fabricate complex 3D components. Also known as electron beam melting (EBM) or electron beam powder bed fusion, the process offers capabilities like build rate, material properties,

MIMアディティブ・マニュファクチャリング

mim additive manufacturing refers to an industrial process to produce small, complex metal parts at high volumes. A composite metal powder feedstock is molded into a green-state shape using injection molding equipment, debound, and then sintered to achieve full density. MIM leverages the geometric flexibility of polymer injection molding and green-forming with the performance capability

ガスアトマイズ金属粉

Gas atomization metal powder refers to a material processing method to produce fine spherical metal powders for applications like metal injection molding (MIM), additive manufacturing, pressing and sintering, thermal spray coatings, powder metallurgy, and more. In gas atomization, molten metal alloys are disintegrated into droplets using high pressure inert gas jets. The droplets rapidly solidify

SLM製造の理解

slm manufacturing is a powder bed fusion additive manufacturing process used across industries. This guide provides a comprehensive look at SLM – how it works, materials, applications, advantages/disadvantages, system suppliers, and more. Overview of Selective Laser Melting (SLM) slm manufacturing is an additive manufacturing process that uses a laser to selectively melt metal powder layer-by-layer

製品

売れ筋商品

3Dプリンティングと積層造形用金属粉末