金属3Dプリント用チタンTi-64

3dプリンティング用チタンTi-64 金属、略称Ti-64は、航空宇宙、医療、自動車、および一般的なエンジニアリングにわたる重要な積層造形用途に広く使用されている航空宇宙グレードのチタン合金です。このガイドでは、組成、機械的特性データ、AM処理の詳細、後処理、用途、コストを含むTi-64粉末冶金の技術的概要を提供します。

3dプリンティング用チタンTi-64 金属、略称Ti-64は、航空宇宙、医療、自動車、および一般的なエンジニアリングにわたる重要な積層造形用途に広く使用されている航空宇宙グレードのチタン合金です。このガイドでは、組成、機械的特性データ、AM処理の詳細、後処理、用途、コストを含むTi-64粉末冶金の技術的概要を提供します。

高い強度対重量比、温度性能、耐腐食性、耐久性を持つチタンは、重要な商業および産業用途のアディティブ・マニュファクチャリングにとって非常に優れた材料です。最新の粉末床融合アプローチによって促進される複雑な設計の自由と組み合わせることで、チタン粉末3dプリンティングは新たな可能性を解き放ちます。この概要ガイドでは、一般的な

卓越した強度対重量比、耐腐食性、生体適合性を持つチタンは、航空宇宙、医療、自動車、産業用途の積層造形において高く評価されている材料です。この概要では、様々なチタンアムパウダー、それらに対応する特性、後処理、主要なグローバルサプライヤー、および産業別の使用例について説明します。チタンamの概要

アルミニウムは、その高い強度対重量比、優れた耐食性、熱特性、機械的性能が評価され、積層造形でよく使用される金属材料です。積層造形アルミニウムの品質とプリンターの能力が向上するにつれて、航空宇宙、自動車、消費者製品、建築の各分野における新たな高価値用途が、複雑なアルミニウム部品製造の恩恵を受けることができます。

ニオブ金属粉末は近年、医療機器、エレクトロニクス、光学、航空宇宙、その他の先端分野での用途が拡大しています。このガイドでは、より優れた特性と性能を実現するために特別に設計された球状ニオブ粉末について詳しく見ていきます。組成、特性から製造方法、用途、サプライヤーに至るまで、すべてを調査します、

titanium ti-64 for 3d printing metal, abbreviated as Ti-64, is an aerospace grade titanium alloy widely used for critical additive manufacturing applications across aerospace, medical, automotive and general engineering. This guide provides a technical overview of Ti-64 powder metallurgy including composition, mechanical properties data, AM processing details, post-treatments, applications, cost analysis, product specifications, and comparisons

With its high strength-to-weight ratio, temperature performance, corrosion resistance and durability, titanium is an exceptional material for additive manufacturing across critical commercial and industrial applications. Paired with the complex design freedoms facilitated by modern powder bed fusion approaches, titanium powder 3d printing unlocks new potential. This overview guide explores common titanium alloys leveraged, corresponding mechanical

With exceptional strength-to-weight ratios, corrosion resistance, and biocompatibility, titanium is a highly valued material for additive manufacturing across aerospace, medical, automotive and industrial applications. This overview explores the different titanium am powders, their corresponding properties, post-processing treatments, leading global suppliers, and example use cases by industry. Overview of titanium am powders Key properties make titanium

Aluminum is a popular metal material choice for additive manufacturing, valued for its high strength-to-weight ratio, excellent corrosion resistance, thermal properties, and mechanical performance. As additive manufacturing aluminum quality and printer capabilities advance, new high-value applications across aerospace, automotive, consumer products and architecture can benefit from complex aluminum part production. This overview covers the advantages

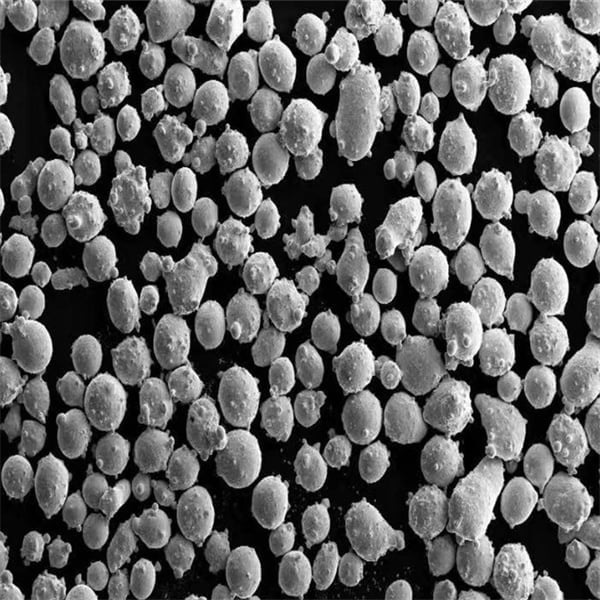

Overview of Additive Manufacturing Powders Additive manufacturing powders refer to metal alloy materials produced in powder form specifically for 3D printing techniques like selective laser melting (SLM), direct metal laser sintering (DMLS), electron beam melting (EBM), and binder jetting. The optimized particle size distributions, morphology, chemistry, and powder properties facilitate precise, layer-by-layer fusion into end-use

Niobium metal powder has found expanding uses across medical devices, electronics, optics, aerospace, and other advanced fields in recent years. This guide takes an in-depth look at spherical niobium powder specifically engineered to deliver enhanced properties and performance. We’ll survey everything from composition and characteristics to production methods, applications, suppliers, specifications, costs, and more surrounding

Additive manufacturing, also known as 3D printing, is revolutionizing production across industries. One of the key materials that makes this possible is metal powder. As additive manufacturing continues rapid growth, understanding metal powders is essential. When we think about metal 3D printing, it’s easy to focus on the mind-blowing printers. Yet none of it works

Overview of electron beam melting machine Electron beam melting (EBM) is an additive manufacturing technology used to fuse metal powders into fully dense parts layer-by-layer using a high power electron beam under vacuum conditions. EBM machines offer unmatched build speeds and mechanical properties unachievable with other metal 3D printing methods. Key attributes of EBM technology

Overview of Molybdenum Metal Powders Molybdenum powder is a refractory metal material produced from molybdenum metal, known for its extremely high melting point, strength at high temperatures, and resistance to wear and corrosion. Key properties make molybdenum powder an ideal choice for manufacturing parts and composites across industries like aerospace, defense, automotive, and power generation.

Overview of electron beam melting equipment Technology electron beam melting equipment is an additive manufacturing technology used to fuse metal powders together layer by layer utilizing a high-power electron beam in a vacuum environment. EBM equipment offers capabilities unmatched by other metal 3D printing methods in terms of build rate, part density, residual stress, and

3Dプリンティングと積層造形用金属粉末