ブログ

すべてのコレクション

球状チタン粉末の紹介

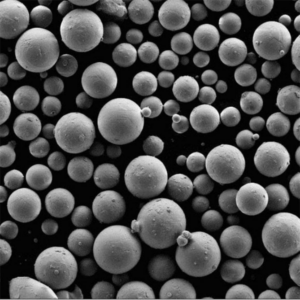

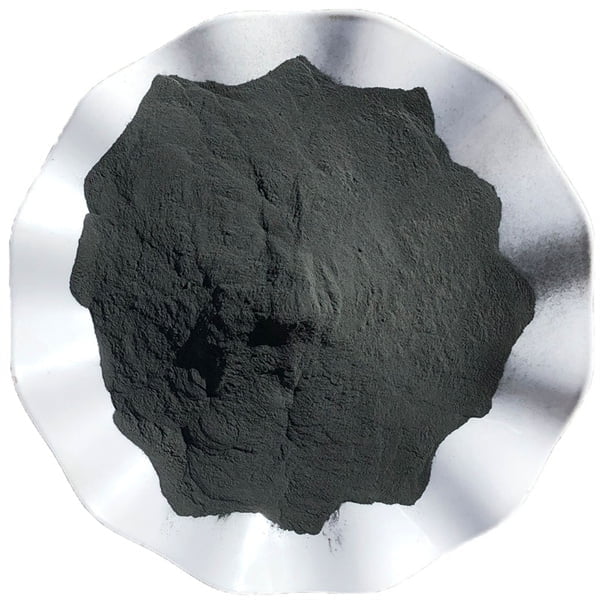

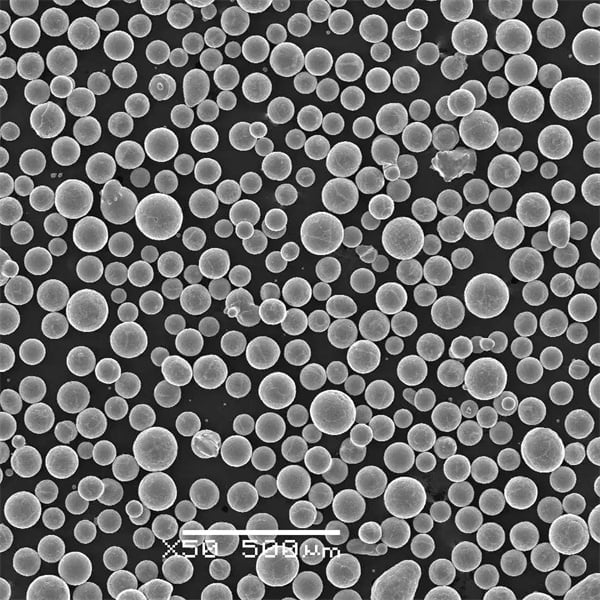

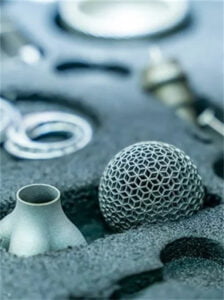

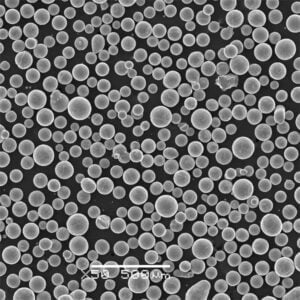

粒子径が制御された球状チタン粉末は、積層造形や粉末冶金プレスによる高強度で軽量なチタン金属部品の製造を可能にします。その高い強度対重量比、耐食性、生体適合性により、チタンは航空宇宙、医療、自動車、その他要求の厳しい用途において魅力的なエンジニアリング材料となっています。本ガイドは、組成、製造方法について説明しています、

積層造形用ステンレス鋼粉末

ステンレス鋼粉末は、従来の金属製造とは比較にならないアディティブ技術を用いた複雑形状の印刷を可能にします。このガイドでは、ステンレスパウダーの調達に役立つ合金の種類、粒子仕様、特性データ、価格に関する洞察と比較について説明します。ステンレスパウダー入門 ステンレスパウダーが提供する主な機能:一般的に使用される合金この

技術者のための耐火金属粉末ガイド

耐火性金属粉末は、他の材料にはない極めて耐熱性の高い合金の積層造形を可能にします。このガイドでは、耐火物粉末の組成、粒子仕様、特性データ、価格、および調達の意思決定に役立つ比較について説明します。耐火性金属粉末の紹介 耐火性粉末が提供する主な機能は以下の通りです:一般的に使用される合金本ガイド

アルミニウム合金粉末

アルミニウム合金粉末は、自動車、航空宇宙、産業用途において、強度、耐久性、耐食性に加え、軽量化を提供します。このガイドでは、一般的な組成、特性、製造方法、サイズ、サプライヤー、用途、および選択について説明します。 アルミニウム合金粉末の概要 粒径を制御した球状アルミニウム粉末は、以下を介して高性能の軽金属部品を可能にします。

金属合金粉末

Metal alloy powders enable manufacturing of high performance parts using powder metallurgy pressing and sintering or additive manufacturing methods across transportation, industrial, medical and energy industries. This guide covers various alloy options, powder production processes, key specifications, use cases, quality considerations and sourcing advisory. Types of metal alloy powders Common categories: Type Examples Key Properties

球状チタン粉末の紹介

spherical titanium powder with controlled particle sizes enables manufacturing of strong, lightweight titanium metal parts using additive manufacturing or powder metallurgy pressing. Its high strength-to-weight ratio, corrosion resistance and biocompatibility make titanium an attractive engineering material across aerospace, medical, automotive and other demanding applications. This guide covers compositions, production methods, specifications, uses, pricing and sourcing

積層造形用ステンレス鋼粉末

Stainless steel powders enable complex geometry printing using additive techniques unmatched by conventional metal manufacturing. This guide covers alloy variants, particle specifications, properties data, pricing insights and comparisons to inform stainless powder procurement. Introduction to Stainless Steel Powders Key capabilities offered by stainless steel powders: Common alloys used include: This guide provides considerations when selecting

技術者のための耐火金属粉末ガイド

Refractory metal powders enable additive manufacturing of extremely heat resistant alloys unmatched by other materials. This guide covers refractory powder compositions, particle specifications, properties data, pricing, and comparisons to inform procurement decisions. Introduction to Refractory Metal Powders Key capabilities offered by refractory powders include: Common alloys used are: This guide provides considerations when selecting refractory

超合金金属粉

superalloys metal powder enable additive manufacturing of high strength, heat resistant alloy components unmatched by conventional metals. This guide covers superalloy compositions, powder specifications, properties data, pricing insights and comparisons to inform powder metallurgy procurement decisions. Introduction to superalloys metal powder Key capabilities of superalloy powders: Common classification groups: This guide provides considerations when selecting

アルミニウム合金粉末

Aluminum alloy powders offer light weighting combined with strength, durability and corrosion resistance across automotive, aerospace and industrial applications. This guide covers common compositions, properties, manufacturing methods, sizes, suppliers, applications and selection. aluminum alloy powder Overview Spherical aluminum powders with controlled particle size enable high performance light metal components via PM, MIM and AM: Alloys

金属成形機

Metal molding machines produce precision net shape components from metallic powders via powder injection molding (PIM) for automotive, aerospace, medical and other demanding applications. This guide provides an overview of PIM equipment types, process steps, key specifications, leading manufacturers and comparative assessment. metal molding machine Overview Metal molding machines facilitate powder injection molding – a

ガス噴霧器

gas atomizer equipment produces fine spherical metal powders with controlled particle size distribution critical across metal AM, thermal spray, MIM and other powder metallurgy applications. This guide covers process principles, atomizer types, system components, operating parameters, manufacturers and comparative assessment. gas atomizer equipment Process Overview Gas atomization uses kinetic energy from high velocity gas jets

チタン金属粉

titanium metal powder metallurgy enables fabricating advanced lightweight structural parts combining high specific strength, corrosion resistance and biocompatibility. This guide covers titanium powder production methods, characteristics, alloying strategies, applications, specifications, pricing, and comparisons against alternative metals. It also includes research directions and expert recommendations on processing titanium powder for optimized properties. Overview Key attributes make

モリブデン金属粉

Molybdenum metal powder is a refractory material valued for its high temperature properties combining strength, thermal conductivity and corrosion resistance. This guide covers molybdenum powder manufacturing processes and characteristics plus molybdenum alloying and applications. It also details product specifications, pricing, suppliers, advantages versus alternatives along with expert recommendations for usage. Overview Essential properties of pure

製品

売れ筋商品

3Dプリンティングと積層造形用金属粉末