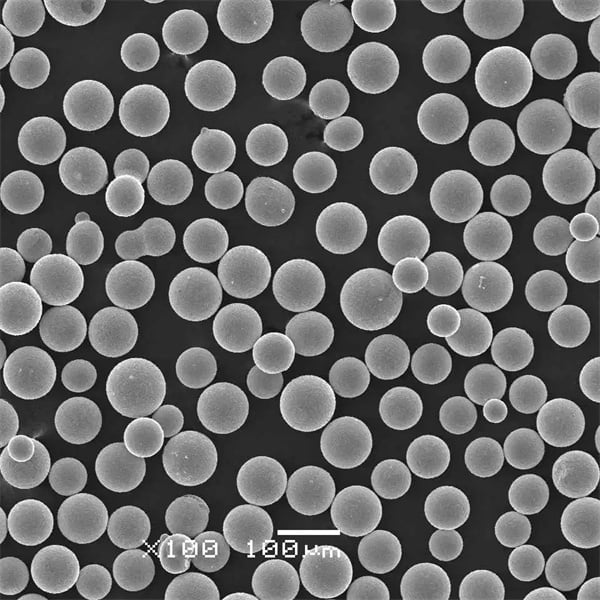

MIMメタルパウダー

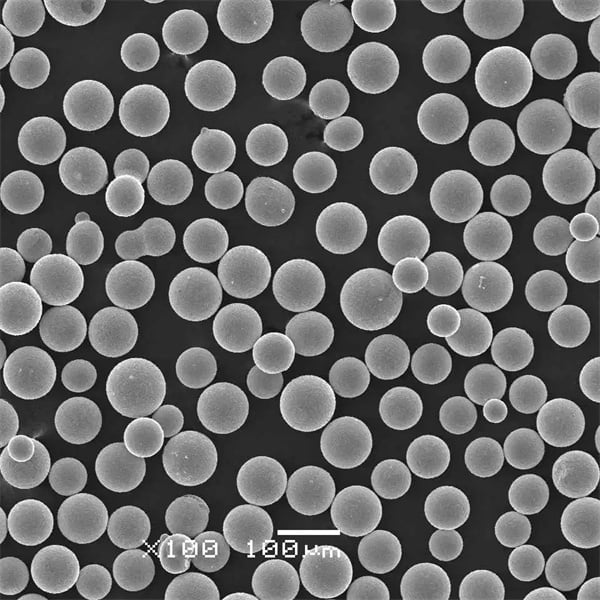

金属粉末射出成形(MIM)は、複雑で高精度の金属部品を大量に生産する能力で人気を集めている製造プロセスである。その中核となるMIMプロセスでは、微細な金属粉末粒子とバインダー材料を混合した原料を利用する。金型に注入すると

金属粉末射出成形(MIM)は、複雑で高精度の金属部品を大量に生産する能力で人気を集めている製造プロセスである。その中核となるMIMプロセスでは、微細な金属粉末粒子とバインダー材料を混合した原料を利用する。金型に注入すると

チタンアルミナイドはチタンとアルミニウムからなる軽量で高強度の金属間合金の一種です。本ガイドブックは、製造方法、組成、主な特徴とパラメーター、サプライヤーと価格、産業にわたる多様な最終用途、FAQなど、粉末状のチタンアルミナイドに関するリファレンスとして役立ちます。概要

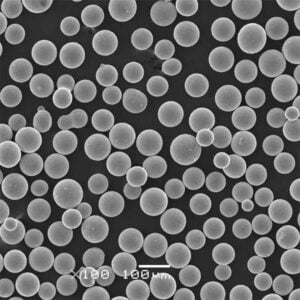

アディティブ・マニュファクチャリング(AM)としても知られる3Dプリンティングは、特殊な粉末を利用して、連続的な積層法で3次元部品を造形します。本ガイドは、3Dプリンティング用パウダーの種類、特徴、仕様、製造方法、主要サプライヤーと価格、各業界における用途、代替品との比較、FAQなど、3Dプリンティング用パウダーの詳細なリファレンスとなっています。

タングステン粉末は、その高い密度、強度、熱安定性により、いくつかの業界全体で重要な材料です。右のタングステン粉末のサプライヤーを選択すると、適切なグレード、品質、およびアプリケーションのサポートを得るために不可欠です。タングステンパウダーの用途 表1:タングステンパウダーの主な用途 産業用途

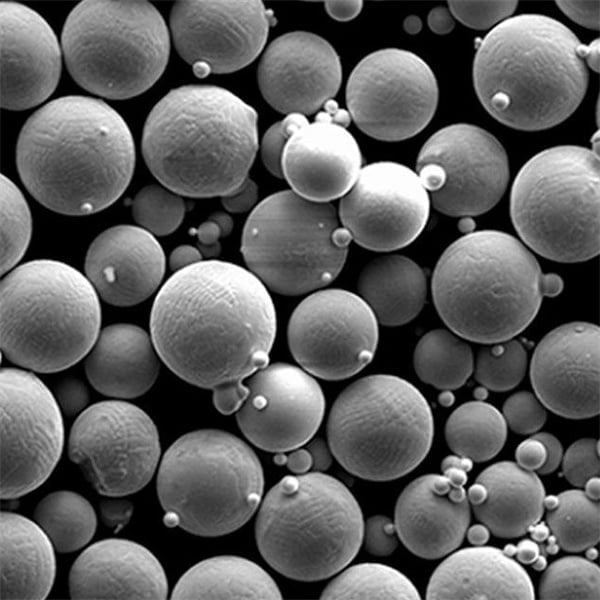

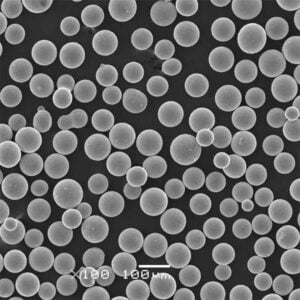

アトマイズパウダーは、アトマイズ法(溶融金属を微細な液滴にして固化させ、粉末粒子とする方法)によって製造される金属または合金粉末の一種です。この粉末製造方法では、粒子径、形状、組成などの粉末特性を精密に制御することができます。アトマイズ粉末は

Metal injection molding, or MIM metal powder, is a manufacturing process gaining popularity for its ability to produce complex, high-precision metal parts in high volumes. At its core, the MIM process utilizes a feedstock consisting of fine metal powder particles mixed with a binder material. When injected into a mold, this feedstock allows intricate shapes

Metal alloy powders refer to particulate blends of two or more metal elements used across manufacturing, additive techniques and research applications. This guide serves as an in-depth reference on metal alloy powders – exploring types, production methods, key properties, specifications, suppliers, pricing, applications, comparisons and more. Overview of Metal Alloy Powders Characteristic Description Composition Metal

Titanium aluminide refers to a class of lightweight, high strength intermetallic alloys composed of titanium and aluminum. This guide serves as a reference on titanium aluminide in powder format – exploring manufacturing methods, compositions, key traits and parameters, suppliers and pricing, diverse end-use applications across industries, FAQs and more. Overview of Titanium Aluminide Powder Titanium

3D printing, also known as additive manufacturing (AM), utilizes specialized powders to construct three-dimensional components in successive layering methods. This guide serves an in-depth reference on powders for 3D printing – exploring types, traits, specifications, manufacturing methods, key suppliers & pricing, applications across industries, comparisons to alternatives, FAQs and more. Overview of 3D Printing Powders

HIP technology or Hot Isostatic Pressing is an advanced manufacturing process to eliminate porosity, increase density, and improve mechanical properties of parts produced via additive manufacturing, casting, powder metallurgy and other techniques. HIP technology Process Table 1: Summary of The Hot Isostatic Pressing Process Parameters Details Principle High temperature + High isostatic gas/liquid pressure to

Gas atomization is a specialized manufacturing process to produce fine metallic powders with precise composition and consistent particle sizes. The powders find application across automotive, aerospace, medical, and industrial sectors. Overview of gas atomized powder Table 1: Summary of the Gas Atomization Process Parameter Details Raw Materials Metals like titanium, aluminum, steels, nickel alloys in

Tungsten powder is a key material across several industries due to its high density, strength, and thermal stability. Choosing the right tungsten powder supplier is vital to get the appropriate grade, quality and support for your application. Applications of Tungsten Powder Table 1: Major Applications of Tungsten Powder Industry Applications Defense Penetrators, radiation shielding Automotive

Atomized powder is a type of metal or alloy powder made by atomization, a process where molten metal is turned into fine droplets that solidify into powder particles. This powder production method allows for precise control over powder characteristics like particle size, shape, and composition. Atomized powders have become an important material across industries like

HIP or hot isostatic pressing uses heat and pressure to consolidate biocompatible metal powders into complex shapes suitable for hip replacement implants needing a balance of strength, longevity and bone integration ability. This guide covers key alloy types, production methods, characteristics, applications, specifications and comparisons of HIP metal powders for hip implants. Overview of HIP

Metal alloy powders refer to fine particulate blends of metal elements that when consolidated create high performance components exploiting customized mechanical, thermal, electrical and corrosion properties unavailable in single metal forms. This guide details composition, production methods, characteristics, applications, specifications and comparisons for widely used nickel, aluminum, steel and titanium alloy powders. Overview of Metal

3Dプリンティングと積層造形用金属粉末