ブログ

すべてのコレクション

アルミニウム合金7050粉末

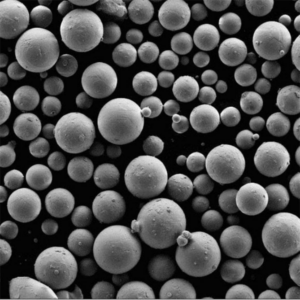

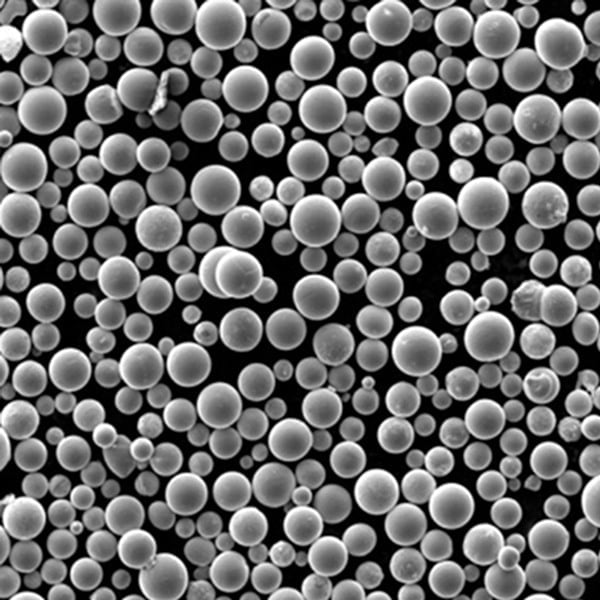

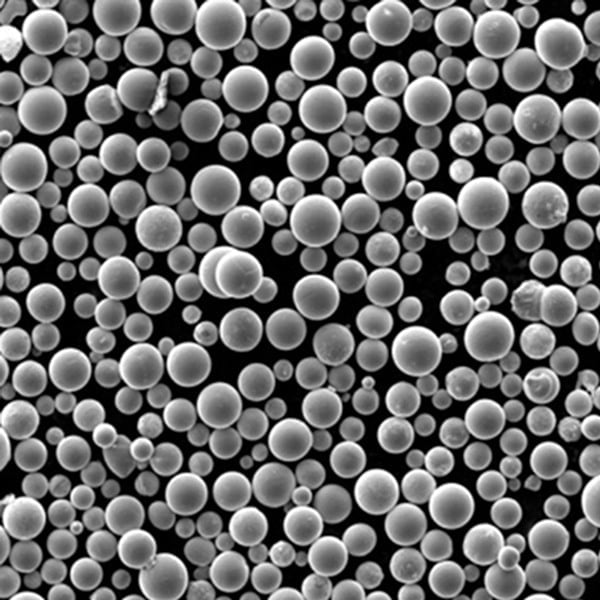

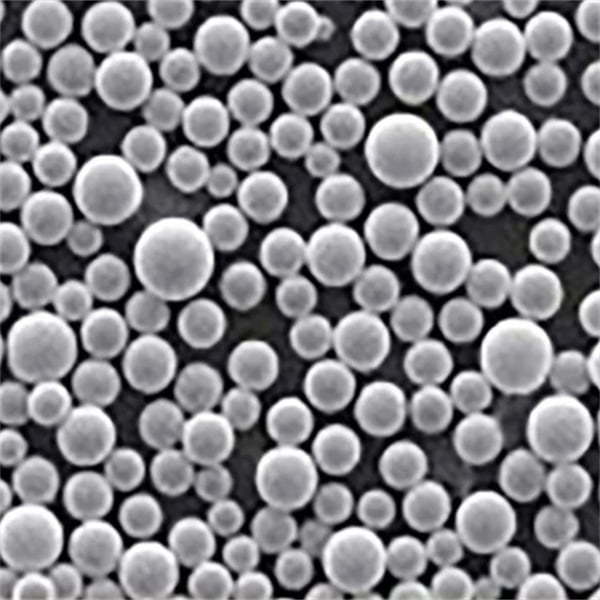

aluminium alloy 7050 powder is a high-strength aerospace alloy also available in powder form for additive manufacturing and other powder metallurgy applications. With zinc and magnesium as primary alloyants, this 7xxx series alloy demonstrates superior mechanical properties ideal for critical structural components. Overview of aluminium alloy 7050 powder Property Description

高密度タングステン粉

高密度タングステン粉末は、タングステンの固有密度が金に匹敵するほど非常に高いため、あらゆる金属粉末の中で最大の密度を有しています。タングステン粉末は、金属粉末の中で最も密度が高く、その密度は金にも匹敵します。タングステン粉末の概要 密度

ニッケルアルミナイドパウダー

ニッケルアルミナイド粉末の概要 ニッケルアルミナイド粉末は、ニッケル(Ni)とアルミニウム(Al)原子が約1:1の割合で結合した金属間化合物である。高強度、高硬度、高温での耐食性、耐酸化性に優れ、密度が低く、耐摩耗性に優れています。ニッケルアルミナイド

モリブデン・チタン粉末

モリブデン・チタン粉末の概要 モリブデン・チタン粉末とは、アトマイズ法により製造される各元素の金属微粒子を指す。高い強度、硬度、耐熱性を示します。粉末は単独で、または高性能合金の製造のためのブレンドとして使用されます。粒度分布が制御されているため、複雑なニアネットシェイプが可能です。

インコネル625パウダー

インコネル625粉末は、優れた強度、耐食性、1000℃までの高温性能で知られるニッケル-クロム-モリブデン合金粉末を指します。この特性の組み合わせにより、インコネル625は、航空宇宙部品から化学処理装置まで、要求の厳しい用途に対応する汎用性の高い超合金となっています。このガイドでは、さまざまなタイプのインコネル

積層造形銅

additive manufacturing copper demonstrate expanding use across additive manufacturing methods, enabling fabrication of highly conductive parts with useful mechanical performance. As one of few metal options across powder bed fusion, binder jetting and directed energy deposition processes, understanding key powder attributes promises growth in applications. Overview of additive manufacturing copper Additive manufacturing using copper promises:

アルミニウム合金7050粉末

aluminium alloy 7050 powder is a high-strength aerospace alloy also available in powder form for additive manufacturing and other powder metallurgy applications. With zinc and magnesium as primary alloyants, this 7xxx series alloy demonstrates superior mechanical properties ideal for critical structural components. Overview of aluminium alloy 7050 powder Property Description Alloy AA7050 UNS Number A97050

高密度タングステン粉

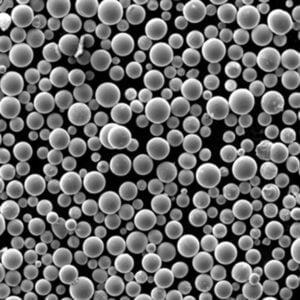

High density tungsten powder possesses the greatest density among all metallic powders owing to tungsten’s extraordinarily high intrinsic density approaching that of gold. This unique attribute allows advanced design of compact, weight-efficient components across diverse sectors harnessing heavy powder pressing and sintering methodologies. Overview of tungsten powder With a density of 19.3 g/cm3 in solid

ニッケルアルミナイドパウダー

Overview of nickel aluminide powder Nickel aluminide powder is an intermetallic compound composed of nickel (Ni) and aluminum (Al) atoms in an approximate ratio of 1:1. It is characterized by high strength and hardness, excellent corrosion and oxidation resistance at high temperatures, low density, and good wear resistance. Nickel aluminide powders are produced by gas

金属噴霧システム

Metal atomization is a manufacturing process where metal is turned into powder form by breaking up molten metal into tiny droplets. This powder can then be used to manufacture parts through methods like metal injection molding, hot isostatic pressing, additive manufacturing, and more. Metal atomization systems are the equipment used to carry out this process.

金属粉末噴霧化

Metal powder atomization is a critical technology for producing fine metallic powders with specialized characteristics. This guide covers the fundamentals, methods, applications and commercial landscape of metal powder atomization. What is Metal Powder Atomization? Metal powder atomization refers to industrial processes that turn molten metal alloys into fine liquid droplets, rapidly solidifying them into powder

ニッケル合金金属粉

Nickel alloys metal powders refer to powder metallurgy forms of various nickel alloy compositions. These powders can be used to manufacture nickel alloy parts and components through methods like metal injection molding, additive manufacturing, and powder pressing and sintering. Overview of Nickel Alloys Metal Powder Nickel alloy powders provide unique properties like high strength, corrosion

316 金属粉末

316 metal powder is a type of stainless steel powder composed primarily of iron, chromium, nickel, and molybdenum. It is widely used in various powder metallurgy, additive manufacturing, and metal injection molding applications due to its excellent corrosion resistance, good mechanical properties, and ability to be 3D printed or sintered into complex parts. Overview of

モリブデン・チタン粉末

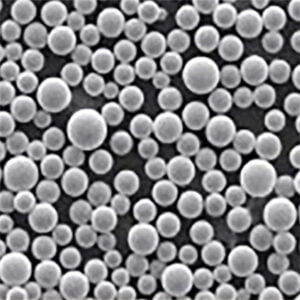

Overview of molybdenum titanium powders molybdenum titanium powders refer to fine metallic particles of each element produced through atomization processes. They display high strength, hardness and heat resistance. The powders are used individually or as blends for manufacturing high performance alloys. Their controlled particle size distribution allows complex near-net shape components to be built up

インコネル625パウダー

Inconel 625 powder refers to a nickel-chromium-molybdenum alloy powder known for excellent strength, corrosion resistance, and high temperature performance up to 1000°C. This combination of properties makes inconel 625 a versatile superalloy for demanding applications ranging from aerospace components to chemical processing equipment. This guide covers different types of inconel 625 powder including gas atomized

製品

売れ筋商品

3Dプリンティングと積層造形用金属粉末