ブログ

すべてのコレクション

ステンレススチール・パウダー

ステンレス鋼粉末は、様々な産業で使用される汎用性の高い素材です。この包括的なガイドでは、ステンレス鋼粉の様々な側面について詳細な情報を提供し、この素材を理解するのに役立ちます。ステンレスパウダーの概要 ステンレスパウダーは、ステンレス鋼を粉砕して作られます。

7075アルミニウム合金パウダー

7075アルミ合金パウダーの概要 7075アルミ合金パウダーは、優れた機械的特性と耐食性を持つ、強力で軽量な粉末冶金材料です。亜鉛を主合金元素として含み、マグネシウム、銅も含むため、多くの鋼に匹敵する非常に高い強度を有します。7075アルミ合金

チタン粉末の3Dプリンティング

チタンパウダーの3Dプリントの概要 チタンは、航空宇宙、自動車、医療、その他の要求の厳しい用途のための複雑な形状を3Dプリントするのに理想的な、強く、軽量で、耐腐食性の金属です。チタンパウダーは、選択的粉末溶融技術のような粉末床溶融技術を使用して、優れた機械的特性を持つフル密度の金属パーツをプリントするために使用することができます。

アルミニウム合金の3Dプリント

3d printing aluminum alloys offer several beneficial characteristics like high strength-to-weight ratio, excellent thermal conductivity, and corrosion resistance that make them suitable materials for 3D printing applications across automotive, aerospace, consumer goods, and other industries. Selective laser melting (SLM) and direct metal laser sintering (DMLS) are the primary 3D printing

3dプリンティングパウダー 供給者

3dプリンティングパウダーサプライヤーの概要 3dプリンティングパウダーは、アディティブ・マニュファクチャリング(積層造形)とも呼ばれ、原材料としてパウダーを使用し、層ごとにコンポーネントを構築する。粉末は、熱、レーザー、結合剤を使用して融合または結合され、3次元の物体が作成されます。アディティブ・マニュファクチャリングで使用される技術はいくつかある。

モリブデンパウダー

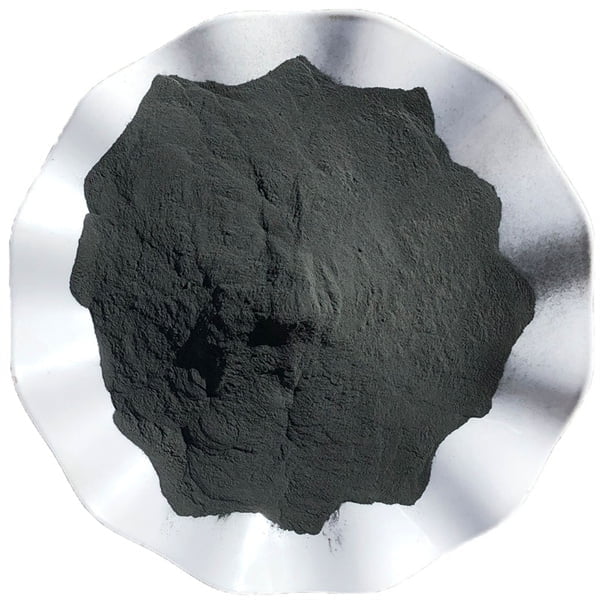

Molybdenum powder is a gray powder made by reducing molybdenum oxide under hydrogen atmosphere. It has unique properties like high melting point, strength, hardness, wear resistance, and ability to withstand extreme temperatures that make it suitable for applications like metallurgy, machinery manufacturing, electronics, and aerospace components. Overview of Molybdenum Powder Molybdenum powder has following key

高純度金属粉

High purity metal powders refer to metallic powders with extremely low levels of impurities, often 99.9% pure or higher. They are utilized across a wide range of advanced applications where contamination-free materials are critical for performance and reliability. Overview of High Purity Metal Powders High purity metal powders possess unique properties that make them indispensable

ステンレススチール・パウダー

Stainless steel powder is a versatile material with applications across many industries. This comprehensive guide provides detailed information on various aspects of stainless steel powder to help you understand this material. Overview of Stainless Steel Powder Stainless steel powder is made from stainless steel that has been crushed into a fine powder form. It exhibits

金属粉末の紹介

Metal powders are fine metal particles used in various manufacturing processes to create metal parts and products. This article provides an in-depth guide on metal powders covering their key properties, production methods, applications, suppliers, costs, and more. Overview of Metal Powders Metal powders are composed of fine particles of metal materials that can be used

7075アルミニウム合金パウダー

Overview of 7075 aluminium alloy powder 7075 aluminium alloy powder is a strong, lightweight powder metallurgy material with excellent mechanical properties and corrosion resistance. It contains zinc as the primary alloying element along with magnesium and copper which give it very high strength comparable to many steels. 7075 aluminium alloy powder can be used to

チタン粉末の3Dプリンティング

Overview of 3d printing titanium powder Titanium is a strong, lightweight, corrosion-resistant metal that is ideal for 3D printing complex geometries for aerospace, automotive, medical, and other demanding applications. Titanium powder can be used to print full-density metal parts with excellent mechanical properties using powder bed fusion technologies like selective laser melting (SLM) and electron

eBM製造プロセス

Electron Beam Melting (EBM) is an additive manufacturing process that uses an electron beam to selectively melt metal powder layer-by-layer to build up fully dense parts. ebm manufacturing process offers capabilities beyond conventional manufacturing methods for producing complex, high-performance metal parts. Overview of ebm manufacturing process EBM works similarly to other powder bed fusion techniques.

金属霧化 メーカー

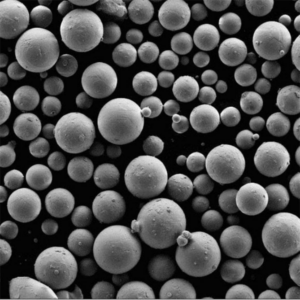

Overview of Metal Atomization Metal atomization is a process where molten metal is broken into fine droplets using gas or liquid that is forced at high velocity. The droplets rapidly solidify into powder with a spherical or round morphology ideal for additive manufacturing or metal injection molding. Atomization produces consistent powder sizes ranging from 10

アルミニウム合金の3Dプリント

3d printing aluminum alloys offer several beneficial characteristics like high strength-to-weight ratio, excellent thermal conductivity, and corrosion resistance that make them suitable materials for 3D printing applications across automotive, aerospace, consumer goods, and other industries. Selective laser melting (SLM) and direct metal laser sintering (DMLS) are the primary 3D printing processes used for aluminum alloy

3dプリンティングパウダー 供給者

Overview of 3d printing powders suppliers 3d printing powders, also known as additive manufacturing, uses powders as the raw material to construct components layer by layer. The powders are fused or bound together using heat, laser, or binding agents to create three dimensional objects. There are several technologies used in 3D printing like Selective Laser

製品

売れ筋商品

3Dプリンティングと積層造形用金属粉末