ブログ

すべてのコレクション

ガスアトマイズプレアロイ球状Ti-6Al-4V

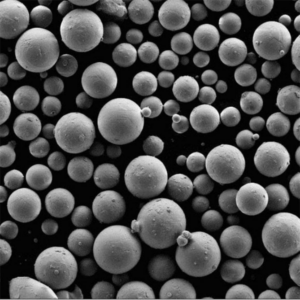

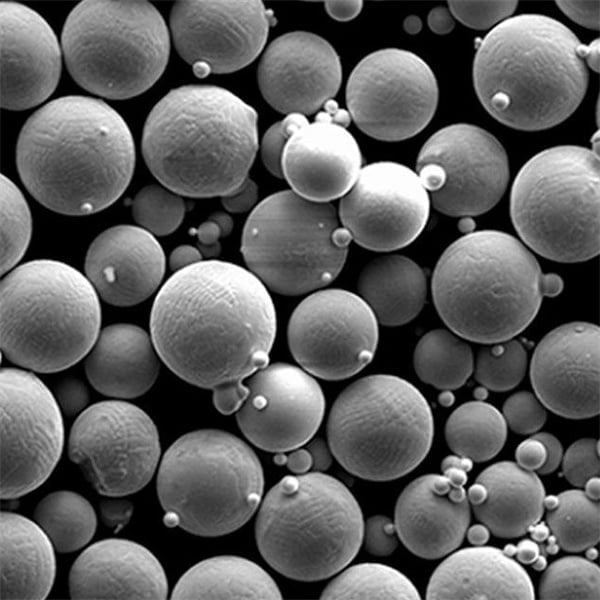

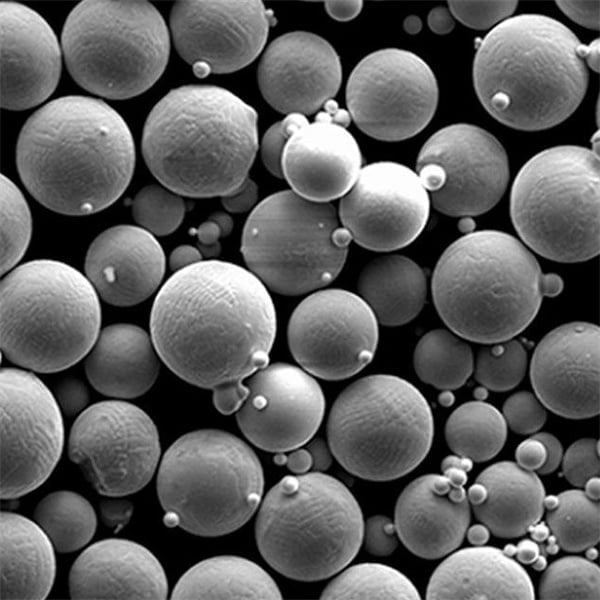

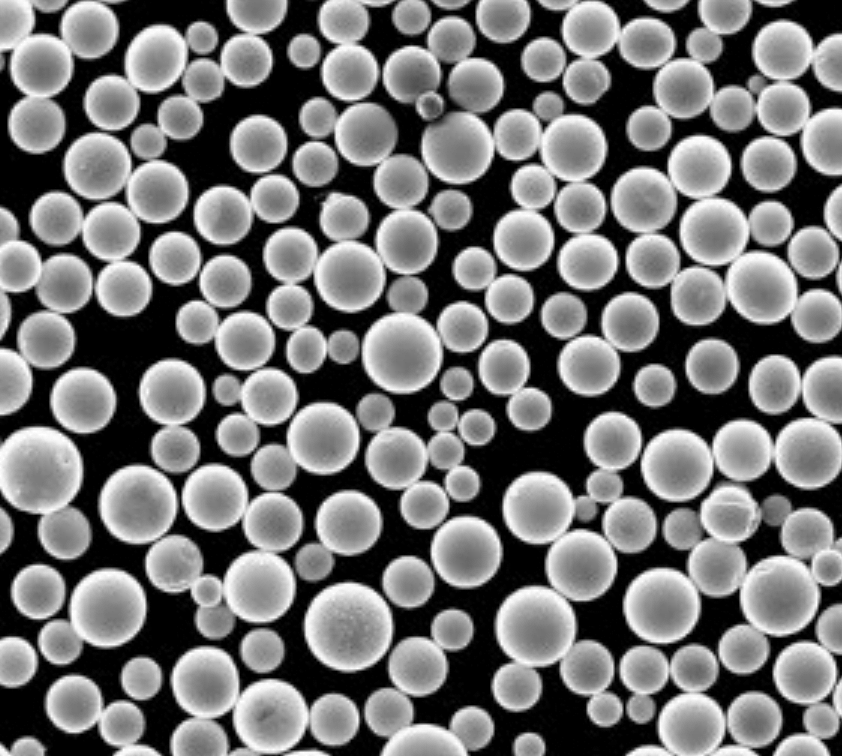

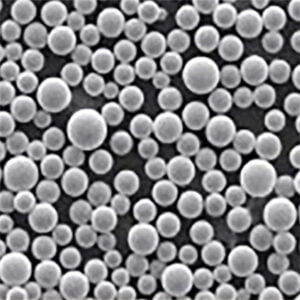

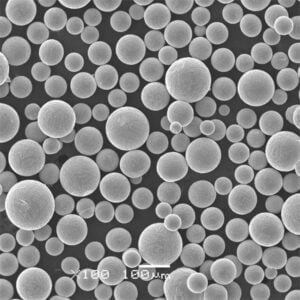

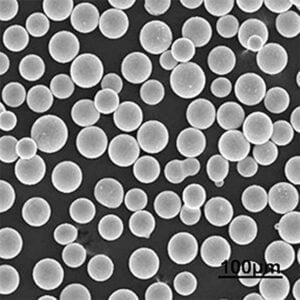

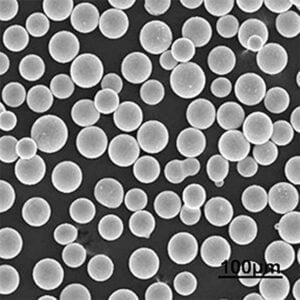

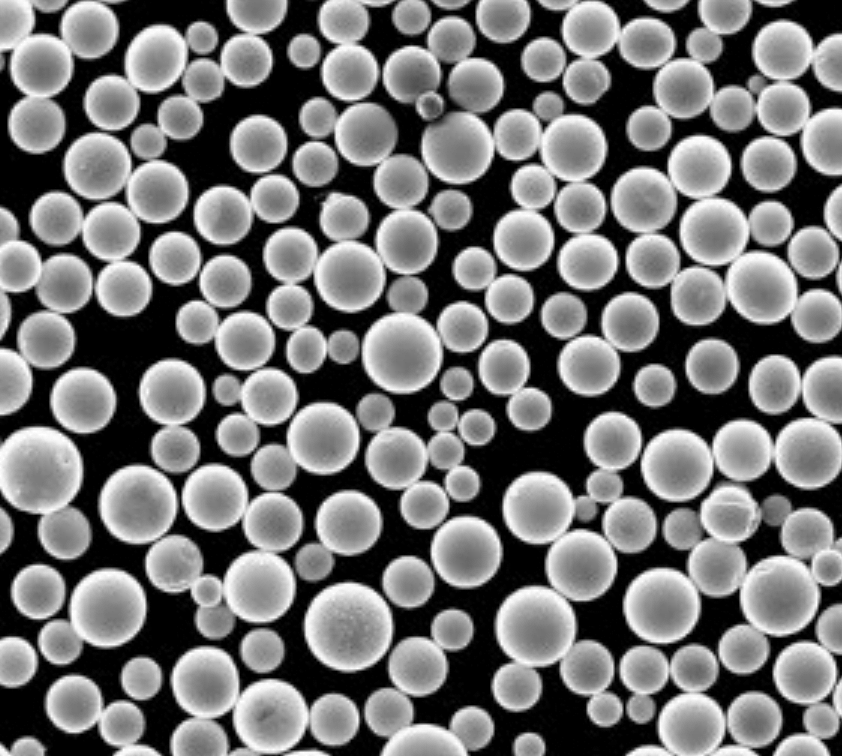

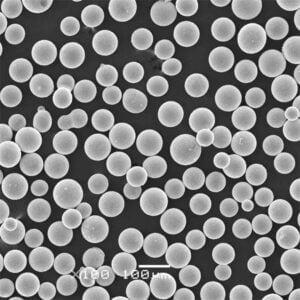

鋼鉄のように強く、羽のように軽い素材を想像してみてください。優れた生体適合性を誇る金属は、人体とシームレスに一体化するインプラントに最適です。これはSFではありません。ガスアトマイズされた球状合金Ti-6Al-4V粉末の現実です。

球状ガスアトマイズ合金粉末

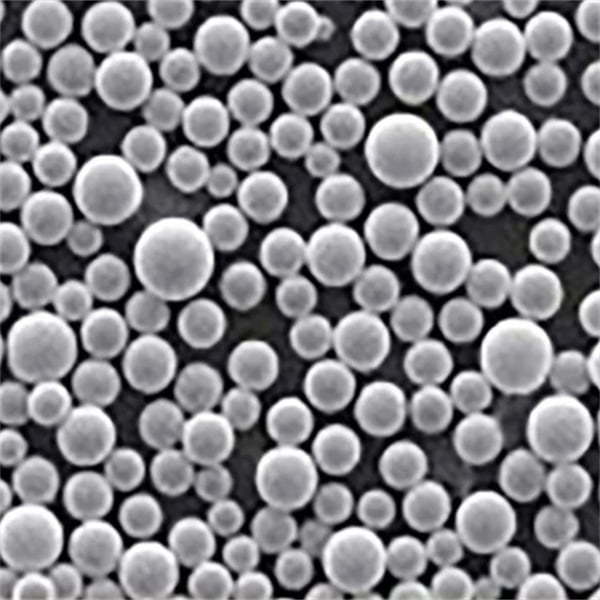

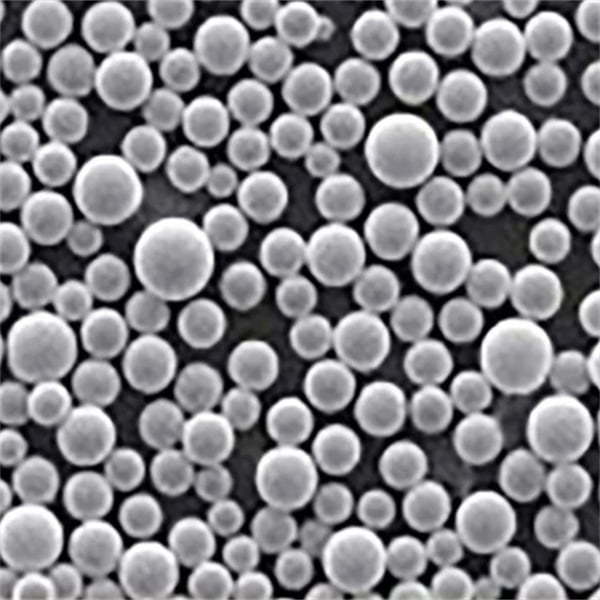

Imagine a world where complex metal parts are crafted not by subtractive processes like machining, but by building them layer by layer. This is the magic of additive manufacturing, also known as 3D printing. But at the heart of this revolution lies a crucial ingredient: spherical gas atomized alloy powder.

プラズマ霧化

Imagine having the ability to transform solid metal into a cloud of perfectly spherical particles, each one microscopic yet immensely powerful. That’s the magic of plasma atomization, a revolutionary technology that’s reshaping the world of metal powders. But what exactly is it, and how does it work? Buckle up, because

PBFテクニック用パウダー

Imagine building intricate metal structures layer by layer, not with rivets and welds, but with lasers and precise manipulation of metal powder. That’s the magic of Powder Bed Fusion (PBF), a revolutionary 3D printing technique that’s transforming the manufacturing landscape. But at the heart of this technology lies a crucial

粉体製造装置ガイド

Imagine a world where complex metal parts are built not through subtractive manufacturing (cutting away material), but by meticulously crafting and shaping tiny metal particles. This fantastical scenario is the very foundation of metal additive manufacturing, also known as 3D printing. But before these metal marvels can take form, they

PREP-ared パウダー

The world of materials science is brimming with fascinating innovations, and PREP-prepared powders are a prime example. But what exactly are they, and why are they causing a stir in various industries? Buckle up, because we’re about to embark on a comprehensive exploration of these metallic marvels, unraveling their secrets

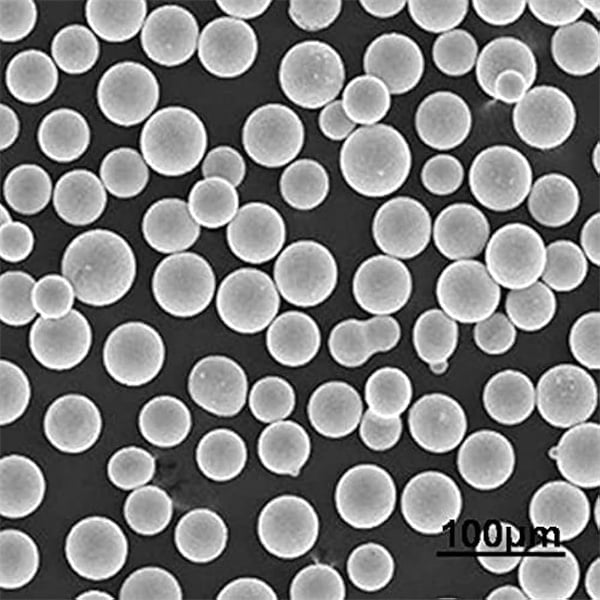

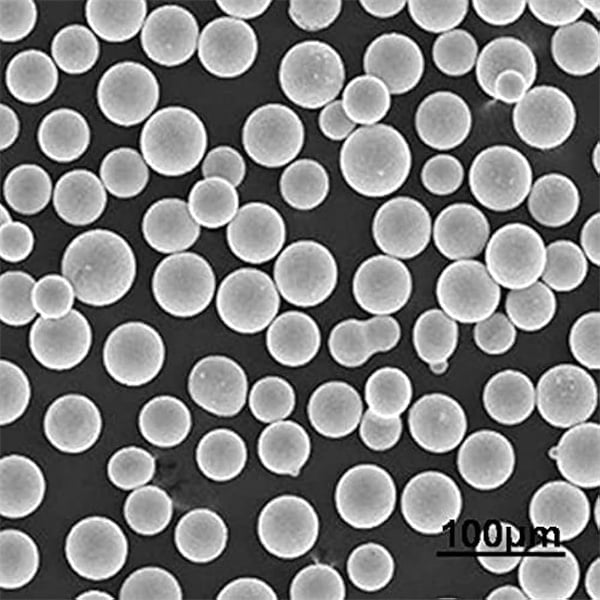

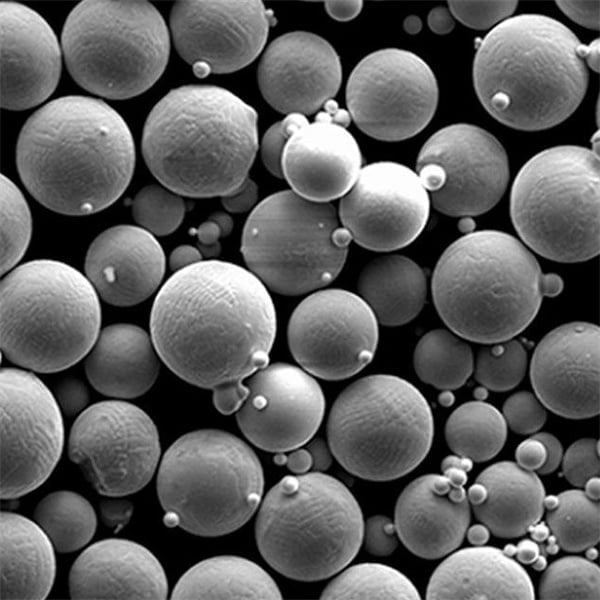

より少ない衛星粒子パウダー

Imagine building intricate objects layer by layer, with each layer a precise deposit of metal powder. This is the magic of Additive Manufacturing (AM), also known as 3D printing. But what if these tiny metal particles, instead of forming a smooth surface, clump together, creating imperfections? This is where the

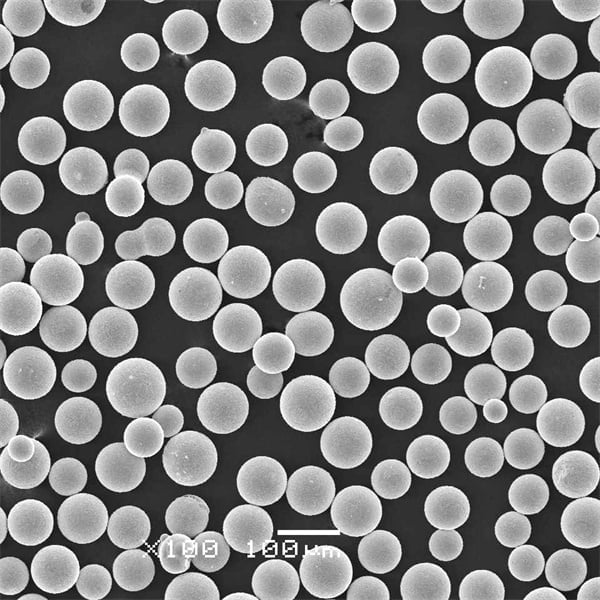

マイナーガス封入孔の粉末

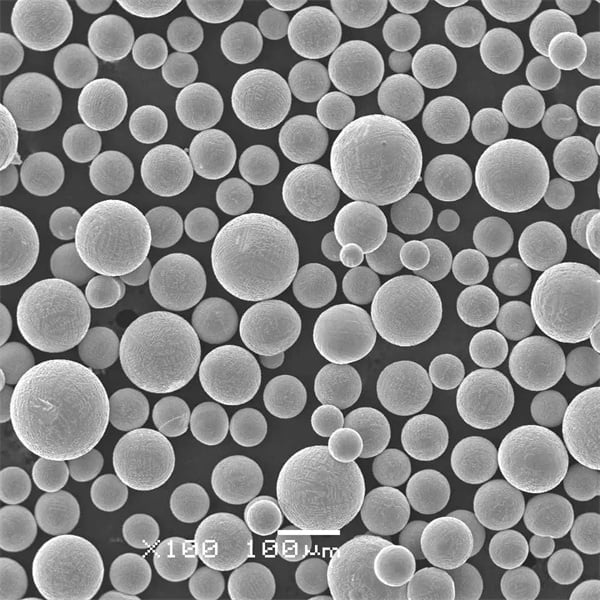

研磨したばかりの木の表面の滑らかで完璧な質感に感心したことはありませんか?その望ましい滑らかさは、ガストラップポアパウダーを使用することで金属部品でも実現できます。しかし、これらのパウダーとは一体何で、どのように魔法の力を発揮するのでしょうか?ガストラップポアパウダーを理解する金属を想像してみてください。

チタンワイヤー

Imagine a material that’s incredibly strong, yet remarkably lightweight. A metal that defies corrosion and tolerates extreme temperatures. That’s the magic of titanium wire. This seemingly unassuming strand packs a powerful punch, finding its way into countless applications across various industries. But before we delve into the world of titanium wire, let’s establish a foundation.

ガスアトマイズプレアロイ球状Ti-6Al-4V

Imagine a material that’s strong as steel, yet light as a feather. A metal that boasts exceptional biocompatibility, making it the perfect choice for implants that seamlessly integrate with the human body. This isn’t science fiction; it’s the reality of gas atomized prealloyed spherical Ti-6Al-4V powder. In the world of metal additive manufacturing (AM), also

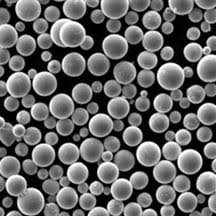

球状ガスアトマイズ合金粉末

Imagine a world where complex metal parts are crafted not by subtractive processes like machining, but by building them layer by layer. This is the magic of additive manufacturing, also known as 3D printing. But at the heart of this revolution lies a crucial ingredient: spherical gas atomized alloy powder. In this comprehensive guide, we’ll

プラズマ霧化

Imagine having the ability to transform solid metal into a cloud of perfectly spherical particles, each one microscopic yet immensely powerful. That’s the magic of plasma atomization, a revolutionary technology that’s reshaping the world of metal powders. But what exactly is it, and how does it work? Buckle up, because we’re about to delve into

PBFテクニック用パウダー

Imagine building intricate metal structures layer by layer, not with rivets and welds, but with lasers and precise manipulation of metal powder. That’s the magic of Powder Bed Fusion (PBF), a revolutionary 3D printing technique that’s transforming the manufacturing landscape. But at the heart of this technology lies a crucial ingredient: the powder itself. In

粉体製造装置ガイド

Imagine a world where complex metal parts are built not through subtractive manufacturing (cutting away material), but by meticulously crafting and shaping tiny metal particles. This fantastical scenario is the very foundation of metal additive manufacturing, also known as 3D printing. But before these metal marvels can take form, they need a crucial starting point:

PREP-ared パウダー

The world of materials science is brimming with fascinating innovations, and PREP-prepared powders are a prime example. But what exactly are they, and why are they causing a stir in various industries? Buckle up, because we’re about to embark on a comprehensive exploration of these metallic marvels, unraveling their secrets and diving into their diverse

より少ない衛星粒子パウダー

Imagine building intricate objects layer by layer, with each layer a precise deposit of metal powder. This is the magic of Additive Manufacturing (AM), also known as 3D printing. But what if these tiny metal particles, instead of forming a smooth surface, clump together, creating imperfections? This is where the concept of “satellite particles” comes

マイナーガス封入孔の粉末

Have you ever admired a freshly sanded wooden surface, its texture smooth and flawless? That desirable smoothness can also be achieved in metal components using minor gas-trapped pore powders. But what exactly are these powders, and how do they work their magic? Understanding Minor Gas-Trapped Pore Powders Imagine a metal component riddled with tiny imperfections

高純度粉末の調製

Imagine a world where materials are crafted with unparalleled precision, where tiny particles hold the key to groundbreaking advancements. This is the realm of high-purity powders, and their preparation is a fascinating dance of science and meticulous engineering. In this comprehensive guide, we’ll delve into the captivating world of high-purity powders. We’ll explore the common

製品

売れ筋商品

3Dプリンティングと積層造形用金属粉末