ブログ

すべてのコレクション

高純度粉末の製造方法

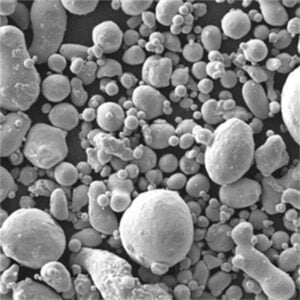

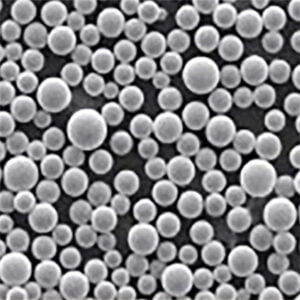

材料が比類のない精度で作られ、その構造が非常に純粋で、画期的な用途を解き放つ世界を想像してみてください。これが高純度パウダーの領域であり、さまざまな産業で性能の限界を押し広げるミクロの驚異である。しかし、この小さな巨人はどのようにして生まれるのだろうか?さあ、潜ってみよう

選択的電子ビーム溶解

複雑な金属物体を、比類のない精度と最も困難な材料でさえ扱う能力で、一層一層作り上げることを想像してみてください。これが選択的電子ビーム溶解(SEBM)の魔法です。この革新的な3Dプリンティング技術は、金属部品の設計と製造の方法を変えようとしています。選択的電子ビーム溶解とは

マルテンサイト系ステンレス鋼

マルテンサイト系ステンレス鋼:名前はスーパーヒーロー映画に出てくるような響きだが、この驚異的な素材は現実世界で大きな威力を発揮する。錆や腐食に強いだけでなく、信じられないほどの強度にまで硬化できる金属を想像してみてほしい。それがマルテンサイト系ステンレス鋼の魔法だ。

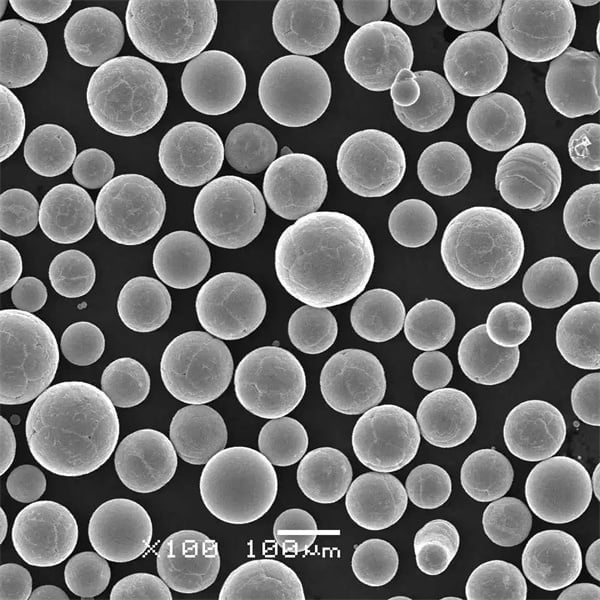

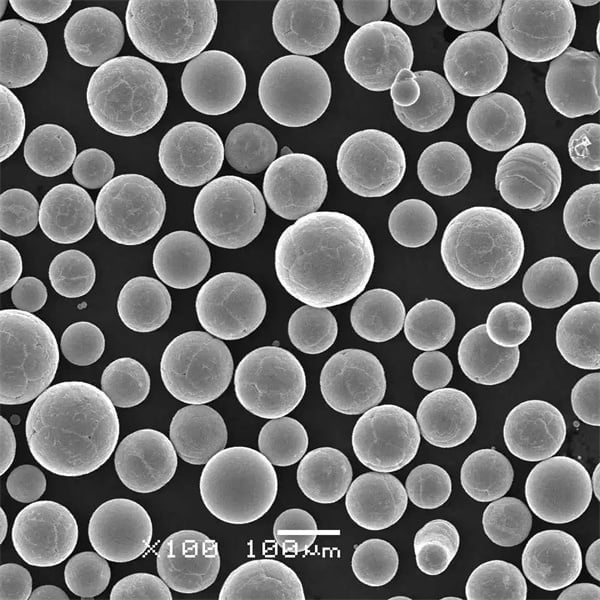

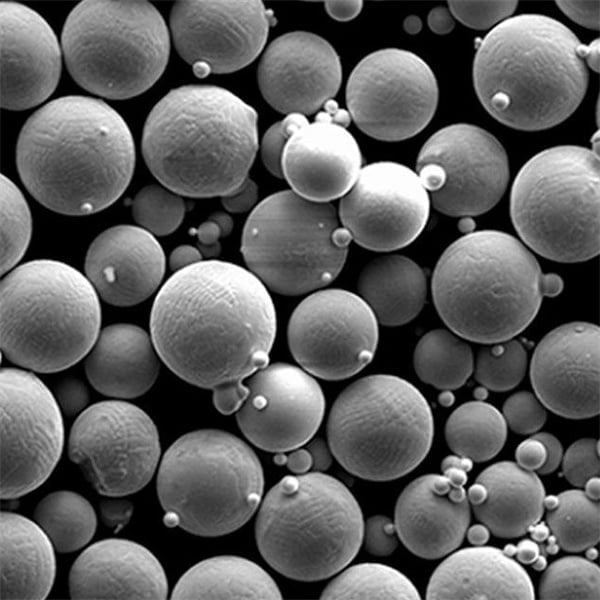

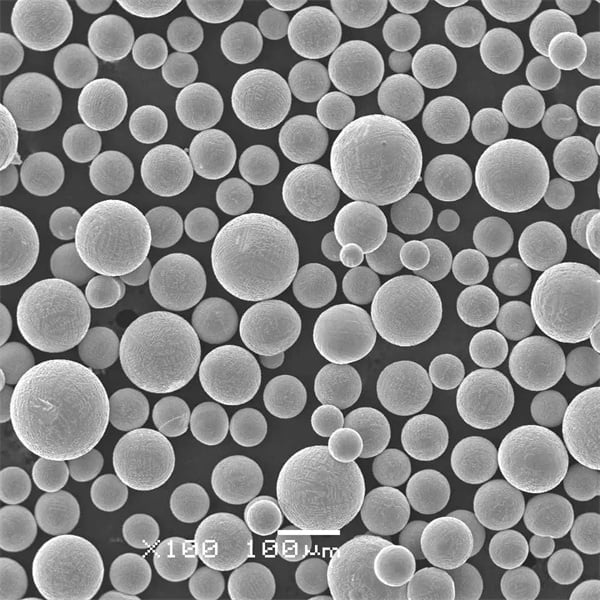

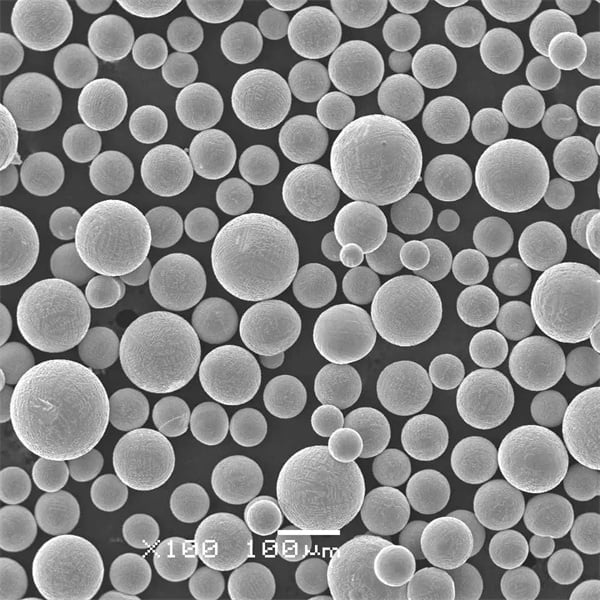

回転霧化

Rotary atomization, a technological marvel lurking beneath the seemingly mundane act of spraying, is a cornerstone of various industries. Imagine transforming a stream of liquid into a fine mist of tiny droplets – that’s the magic of rotary atomization. But this technology goes beyond mere aesthetics; it unlocks a world of possibilities, from creating high-performance

耐火合金の紹介

Refractory alloys are fascinating materials that play a critical role in numerous high-temperature applications. They are designed to withstand extreme environments, such as those found in aerospace, nuclear reactors, and advanced manufacturing processes. This comprehensive guide will delve into the world of refractory alloys, discussing their types, properties, applications, and much more. Overview of Refractory

反応性合金の紹介

Types of Reactive Alloys Here, we present specific metal powder models of reactive alloys, detailing their compositions, properties, and characteristics. Alloy Model Composition Properties Characteristics Ti-6Al-4V Titanium, Aluminum, Vanadium High strength-to-weight ratio, corrosion-resistant Widely used in aerospace and biomedical implants NiTi (Nitinol) Nickel, Titanium Shape memory, superelasticity Used in medical devices and actuators Al-Mg (Magnalium)

鋼滴の急速凝固

Overview Rapid solidification is a cutting-edge technology in the field of metallurgy, particularly for the production of steel droplets. This process involves the ultra-quick cooling of molten steel to form fine microstructures that enhance the material’s properties. In this article, we’ll dive deep into the specifics of rapid solidification, the types of steel powders produced,

高純度粉末の製造方法

Imagine a world where materials are crafted with unparalleled precision, their structure so pure it unlocks groundbreaking applications. This is the realm of high-purity powders, microscopic marvels that push the boundaries of performance across diverse industries. But how do these tiny titans come to be? Buckle up, because we’re diving deep into the fascinating processes

選択的電子ビーム溶解

Imagine crafting complex metal objects layer by layer, with unparalleled precision and the ability to handle even the most challenging materials. That’s the magic of Selective Electron Beam Melting (SEBM), a revolutionary 3D printing technology that’s transforming the way we design and manufacture metal components. What is selective electron beam melting? selective electron beam melting

マルテンサイト系ステンレス鋼

Martensitic stainless steel: the name might sound like something out of a superhero movie, but this wonder material packs a serious punch in the real world. Imagine a metal that’s not only resistant to rust and corrosion but can also be hardened to incredible strength – that’s the magic of martensitic stainless steel. In this

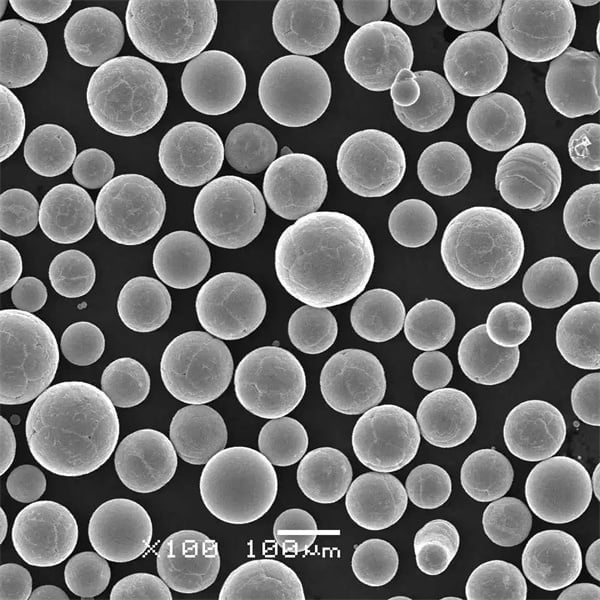

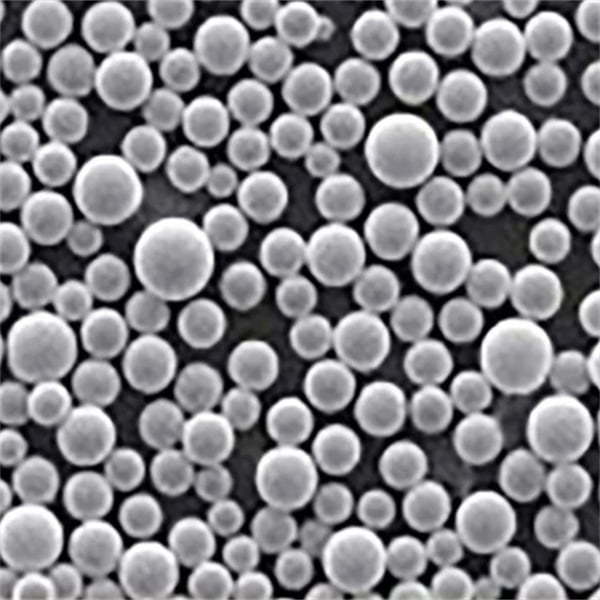

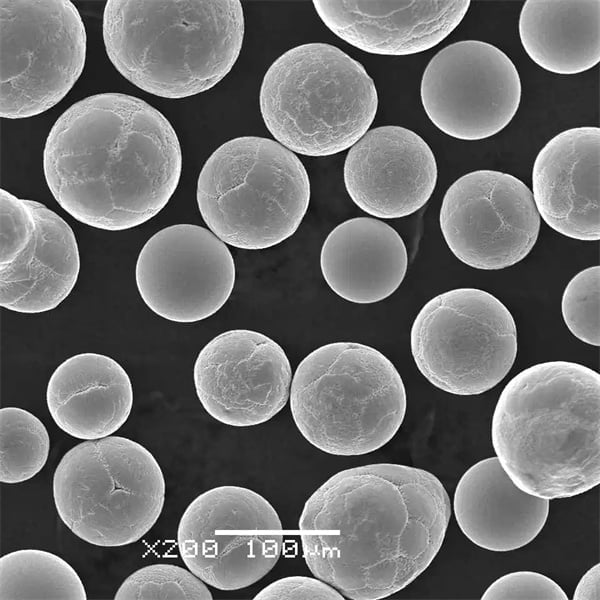

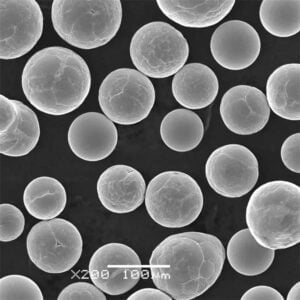

プラサム霧化

Imagine a sculptor, not wielding a chisel and hammer, but wielding a high-tech torch that breaks down molten metal into perfectly spherical particles. That’s the essence of plasam atomization, a transformative technology that’s revolutionizing the way we create advanced materials. What is plasam atomization? Plasma atomization utilizes the intense heat and power of plasma, a

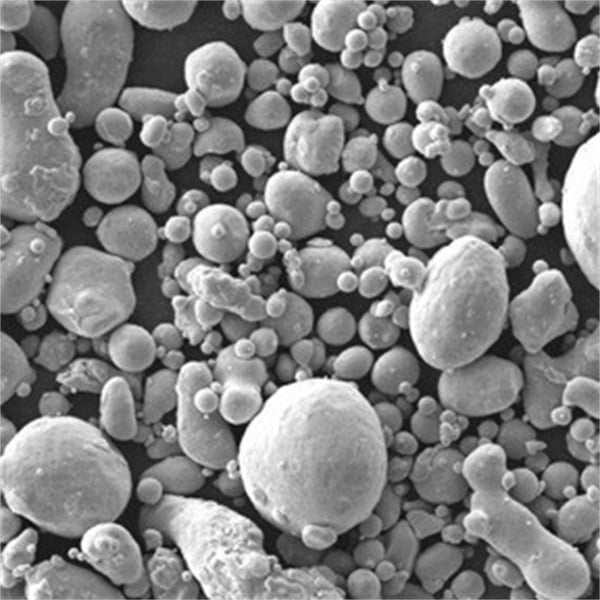

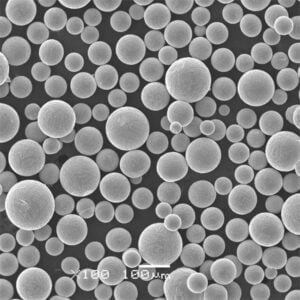

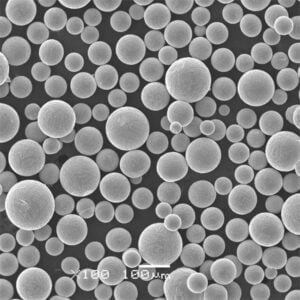

霧化プロセス

Imagine a sculptor, meticulously chipping away at a massive block of stone, transforming it into a delicate figurine. The atomization process operates on a similar principle, but instead of chisels and stone, it utilizes high-powered jets to break down molten metals or liquids into minuscule, highly-functional particles. This article delves deep into the fascinating world

高周波誘導溶解

Imagine a furnace that heats metal not with flames or burning fuel, but with the invisible power of electricity. This isn’t science fiction; it’s the reality of high frequency induction melting, a revolutionary technology transforming the way we melt metals, particularly metal powders. What is High Frequency Induction Melting? High frequency induction melting (HFIM) utilizes

製品

売れ筋商品

3Dプリンティングと積層造形用金属粉末