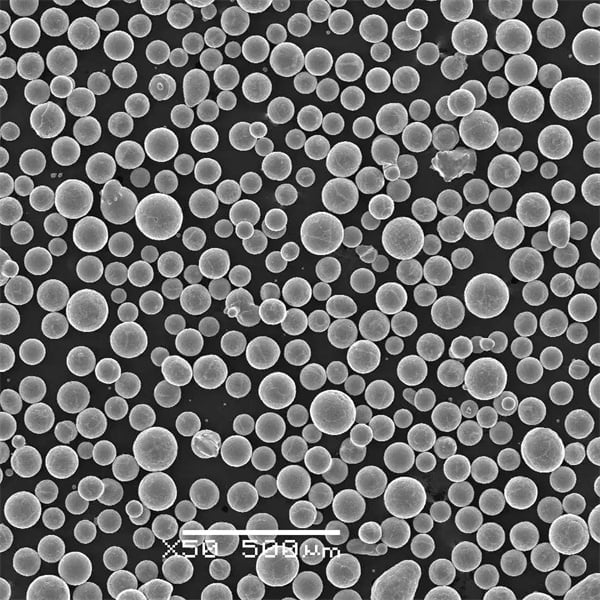

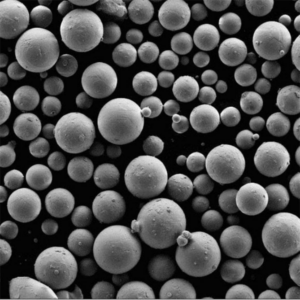

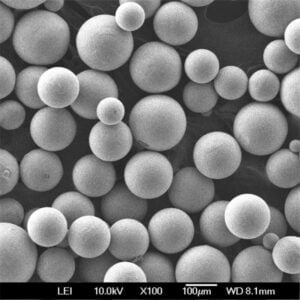

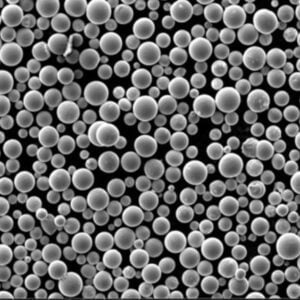

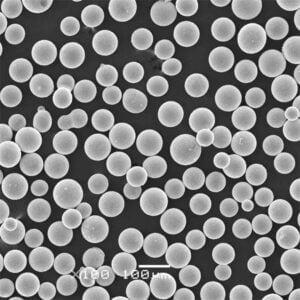

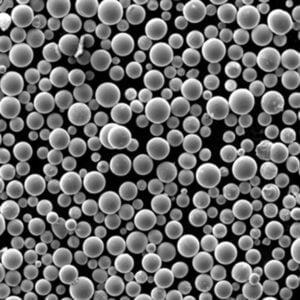

Poudre d'acier maraging 300

La poudre d'acier maraging 300 est une poudre d'acier allié contenant généralement environ 18% de nickel, 8,5% de cobalt, 3% de molybdène, 0,6% de titane et des traces d'aluminium. Il se caractérise par une résistance et une ténacité élevées, ainsi que par une bonne soudabilité.

Faible MOQ

Les quantités minimales de commande sont peu élevées, ce qui permet de répondre à différents besoins.

OEM ET ODM

Fournir des produits et des services de conception personnalisés pour répondre aux besoins uniques des clients.

Stock suffisant

Assurer un traitement rapide des commandes et fournir un service fiable et efficace.

Satisfaction des clients

Fournir des produits de haute qualité en mettant l'accent sur la satisfaction du client.

partager ce produit

Table des matières

La poudre d'acier maraging 300 est une poudre d'acier allié contenant généralement environ 18% de nickel, 8,5% de cobalt, 3% de molybdène, 0,6% de titane et des traces d'aluminium. Il se caractérise par une résistance et une ténacité élevées, ainsi que par une bonne soudabilité.

Vue d'ensemble

Maraging steel 300 powder has the following key characteristics:

- Ultrahigh strength grade of maraging steel in powder form

- Achieves strength levels of 300 ksi (2068 MPa) and higher

- Retains good fracture toughness compared to other high strength alloys

- Composition allows heat treatment to produce optimal strength

- Powder metallurgy process enables complex part production

- Used in aerospace, tooling, and other critical applications

Propriétés principales :

- Very high yield and tensile strength

- Bonne résistance à la rupture

- Excellente stabilité dimensionnelle

- Ease of machining prior to aging treatment

- Good weldability in aged condition

- Resistant to stress corrosion cracking

Composition

The nominal composition of maraging steel 300 powder is:

| Élément | Poids % |

|---|---|

| Nickel | 17 – 19% |

| Cobalt | 7 – 9% |

| Molybdène | 2.75 – 3.25% |

| Titane | 0.6 – 0.8% |

| Aluminium | 0.05 – 0.15% |

| Manganèse | 0 – 0.1% |

| Silicium | 0 – 0.1% |

| Soufre | 0 – 0.01% |

| Phosphore | 0 – 0.01% |

| Carbone | 0 – 0.03% |

| Le fer | Équilibre |

The key alloying elements like nickel, cobalt and molybdenum provide the matrix strengthening needed to reach ultrahigh strength levels. Titanium is a crucial addition for grain size control. Aluminum enhances the aging process.

Propriétés

The properties obtained after appropriate heat treatment of maraging steel 300 powder are:

| Propriété | Valeur |

|---|---|

| Mécanique | |

| Limite d'élasticité | 276 – 317 ksi (1900 – 2200 MPa) |

| Résistance à la traction | 303 – 330 ksi (2100 – 2275 MPa) |

| Élongation | 8 – 15% |

| Réduction de la surface | 25 – 70% |

| Dureté | 48 - 52 HRC |

| Physique | |

| Densité | 0.282 – 0.287 lb/in3 (7.8 – 7.9 g/cm3) |

The ultrahigh strength levels are achieved through solid solution strengthening and heat treatment to enable precipitate hardening. It also retains comparatively good fracture toughness. These properties make it well suited to critical components in aerospace and other demanding industries.

Traitement thermique

The heat treatment process typically involves:

- Solution Treatment: Heating at 1100°F (593°C) for 1 hour then air cool/oil quench. Produces softened state for easy machining.

- Aging Treatment: Heat 450 – 1200°F (230 – 650°C) for 1 – 6 hours then air cool to room temperature. Enables precipitation hardening to achieve full high strength.

Aging at lower temperatures results in higher tensile strength but lower elongation values. The heat treatment can be modified as per required mechanical properties.

Applications

Typical applications of maraging steel 300 powder include:

- Aérospatiale et composants d'aéronefs

- Military equipment

- Enveloppes de moteurs-fusées

- Aubes de turbine

- Outillage industriel

- Pressure vessels

- Bielles

- Engrenages

- Cams

- Fasteners and springs

It allows reliable performance under high dynamic stresses at lighter weights compared to other aerospace materials. Components include critical structural parts, engine and transmission elements. The powder metallurgy approach facilitates fabrication of complex or irregular shapes.

Fournisseurs et prix

Some of the major suppliers of maraging steel 300 powder include:

| Fournisseur | Désignation du produit | Fourchette de prix |

|---|---|---|

| Sandvik Osprey | MARAGE 300 | $45 - $55 par kg |

| Additif pour charpentier | MARAGE 300 | $50 – $60 per kg |

| Praxair | MAR 300 | $48 – $58 per kg |

| Erasteel | M300 | $46 – $56 per kg |

Pricing can vary between $45 – $60 per kg based on order volume, additional processing, delivery schedules, and regional factors. Generally sold in small lots for additive manufacturing uses. Large quantity pricing may be negotiated with suppliers.

Normes

There are currently no formal specifications for the composition and properties of maraging steel 300 powder since it is designed primarily for additive manufacturing rather than conventional casting/forging.

However suppliers conform to established standards for wrought maraging 300 grade in terms of composition limits and achieving the intended strength levels through adequate heat treatment. Testing standards are also matched.

Comparaison avec les alternatives

Vs. Maraging Steel 250 Grade:

- Maraging 300 has 12-15% higher strength

- Maraging 250 is slightly tougher

- Maraging 300 is more expensive

Vs. Stainless Steels:

- 5-7 times higher strength than precipitation hardened stainless steels

- Better fracture toughness than most stainless grades

- Plus cher que les aciers inoxydables

Vs. Carpentry Tool Steels:

- 2-3 times higher strength than cold work tool steels

- Much better toughness especially in larger sections

- More dimensionally stable during heat treatment

- Difficult to grind or polish compared to tool steels

Limites

- Expensive alloy powder

- Requires controlled heat treatment

- Section size is limited for critical applications

- Not easily welded or joined after aging treatment

- Low oxidation and corrosion resistance

Amélioration de la résistance à la corrosion can be achieved by adding 1-3% chromium to produce maraging stainless types.

FAQ

Q : À quoi sert l'acier maraging ?

A: Maraging steels offer very high strength coupled with good fracture toughness, making them suitable for critical static and dynamic load bearing components in aerospace, defense, motorsports, tooling, and other demanding industries.

Q: Why is maraging steel so strong?

A: Maraging steels are ultrahigh strength because of precipitation hardening through heat treatment of an alloy composition containing key elements like nickel, cobalt, molybdenum and titanium. This facilitates a transformation in the molecular structure to make it extremely hard and resistant to dislocation movement.

Q: What is powder metallurgy maraging steel?

A: It refers to producing components from maraging steel powder using additive manufacturing methods like laser powder bed fusion, binder jetting or directed energy deposition. This enables more freedom of design compared to conventional forging and machining. It results in equivalent or better properties after heat treatment.

Q: Is maraging steel brittle?

A: No, unlike other ultrahigh strength steels, maraging grades retain comparatively good fracture toughness and resistance to crack propagation. However section size is limited for critical applications. With optimal aging treatment they offer a good balance of strength, ductility and impact toughness.

Q: Can you weld maraging steel?

A: Maraging steels in the annealed/solutionized state can be welded using conventional or solid-state methods. But welding in the hardened condition is more difficult requiring specialized procedures. Joined components may need re-solutionizing and re-aging heat treatments to restore properties.

Obtenir le dernier prix

À propos de Met3DP

Catégorie de produits

HOT SALE

CONTACTEZ-NOUS

Vous avez des questions ? Envoyez-nous un message dès maintenant ! Nous répondrons à votre demande avec toute une équipe dès réception de votre message.