Imagine a world where complex aircraft components can be built layer by layer, on-demand, with minimal waste. This isn’t science fiction; it’s the reality of Directed Energy Deposition (DED), a cutting-edge additive manufacturing (AM) technology rapidly transforming the aerospace industry.

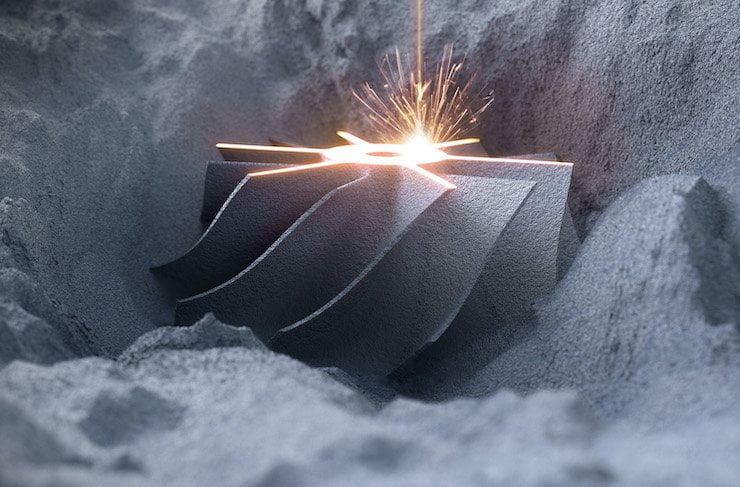

DED, also known as Laser Engineered Net Shaping (LENS), utilizes a focused energy source, like a laser or electron beam, to melt and deposit metallic powder, meticulously building a three-dimensional object. Think of it like a high-tech 3D printer for metal, offering unparalleled design freedom and customization for aerospace applications.

But how exactly is DED taking the aerospace industry by storm? Buckle up, as we delve into the fascinating world of DED applications, explore the diverse metal powders used, and answer some burning questions about this revolutionary technology.

DED: A Game Changer for Aerospace Manufacturing

Traditionally, aerospace components were crafted through conventional methods like casting, forging, and machining. These processes often result in significant material waste and limitations in design complexity. DED disrupts this paradigm by offering a multitude of advantages:

- Lightweighting: DED allows for the creation of intricate, hollow structures, significantly reducing weight – a critical factor for fuel efficiency and payload capacity in aircraft.

- Design Freedom: Unconstrained by traditional manufacturing limitations, DED enables the creation of complex geometries with internal channels and lattices, optimizing performance and weight distribution.

- Rapid Prototyping: DED allows for rapid fabrication of prototypes, accelerating the design and development cycle for new aerospace components.

- On-Demand Manufacturing: DED facilitates the creation of spare parts at the point of need, reducing dependence on pre-manufactured components and minimizing downtime.

- Material Efficiency: DED utilizes a near-net-shape approach, minimizing material waste compared to traditional methods.

- Repair and Restoration: DED can be used to repair damaged components, extending their lifespan and reducing the need for expensive replacements.

These benefits translate to a range of exciting applications in the aerospace field:

- Manufacturing Aircraft Engine Components: DED is making waves in the production of complex engine components like turbine blades, combustors, and heat exchangers. DED allows for the creation of components with advanced internal cooling channels, enhancing efficiency and performance.

- DED for Aircraft Fuselage and Other Structural Components: DED’s ability to create lightweight, high-strength structures makes it ideal for manufacturing aircraft fuselage sections, landing gear components, and other structural elements.

- Customization and Repair: DED empowers on-demand customization of aircraft parts, allowing for modifications to meet specific mission requirements. Additionally, DED can be used for in-situ repair of damaged components, reducing maintenance downtime and costs.

Metal Powders: The Building Blocks of DED Success

The success of DED hinges on the specific metal powders used. These powders, with precisely controlled size and morphology (shape), play a crucial role in the quality and performance of the final product. Here’s a peek at some of the most common metal powders employed in aerospace DED applications:

| **Metal Powder | Description | Properties |

|---|---|---|

| Inconel 625 | A versatile nickel-chromium-based superalloy known for its exceptional high-temperature strength, oxidation resistance, and good weldability. | Offers excellent mechanical properties at elevated temperatures, making it ideal for turbine blades, combustors, and other hot-section components. |

| Titanium 6Al-4V | A high-strength, low-weight titanium alloy widely used in the aerospace industry. | Provides a good balance of strength, ductility, and weight savings, making it suitable for airframe components, landing gear parts, and engine mounts. |