Additive Manufacturing Copper

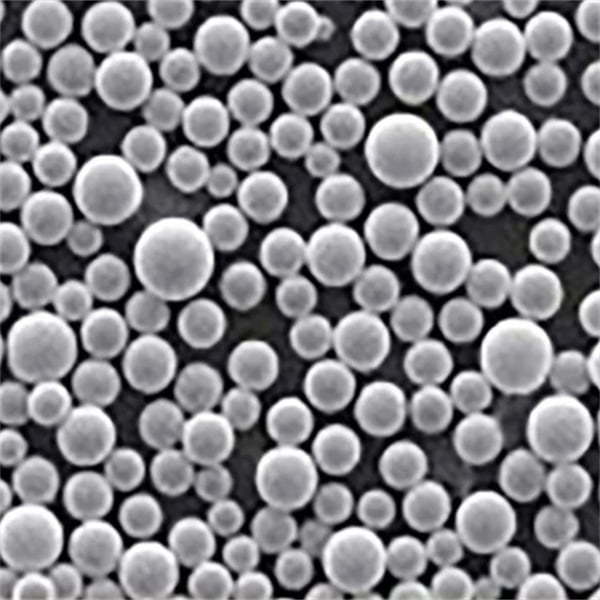

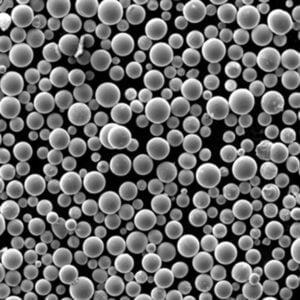

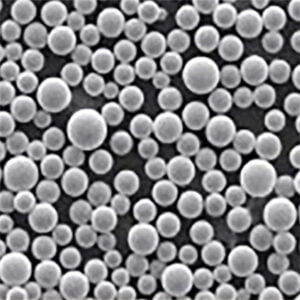

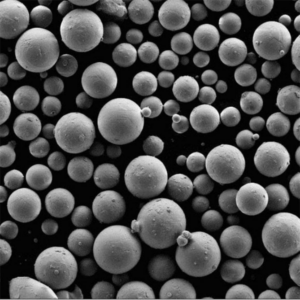

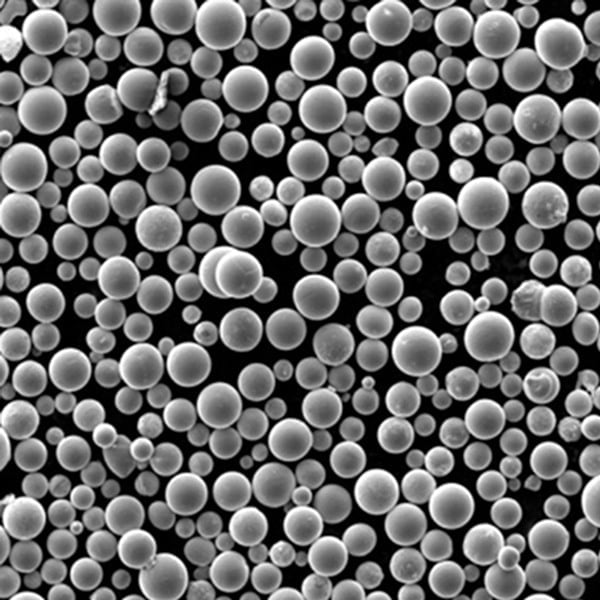

additive manufacturing copper demonstrate expanding use across additive manufacturing methods, enabling fabrication of highly conductive parts with useful mechanical performance. As one of few metal options across powder bed fusion, binder jetting and directed energy deposition processes, understanding key powder attributes promises growth in applications. Overview of additive manufacturing copper