AlSi10Mg is a popular aluminum alloy used in metal 3D printing, offering a good combination of mechanical properties, weight, corrosion resistance and printability. This article provides a comprehensive overview of AlSi10Mg including its composition, properties, print parameters, applications, suppliers and more to inform your metal AM decisions.

Overview of AlSi10Mg Alloy

AlSi10Mg is an aluminum casting alloy with excellent strength, weldability and corrosion resistance. With a low density compared to steels, it enables lighter weight finished parts. The addition of silicon and magnesium results in good flow characteristics, making AlSi10Mg a widely used alloy in various metal 3D printing processes.

Key properties and characteristics:

- Aluminum alloy with 10% silicon, 0.3% magnesium

- Low density – 2.68 g/cm3

- Good strength and hardness

- Excellent corrosion resistance

- Good weldability and machinability

- Widely available, relatively low cost

- Requires heat treatment to optimal mechanical properties

Metal 3D printing processes: Selective laser melting (SLM), Electron beam melting (EBM), Direct metal laser sintering (DMLS)

Applications: Aerospace, automotive, motorsports, industrial components, healthcare

Standards: AMS 4150, AlSi10Mg(Fe)

Mechanical Properties of AlSi10Mg Parts

AlSi10Mg is precipitation hardened to achieve optimal strength and hardness through heat treatment. Exact property values vary based on build parameters, orientation and post-processing.

AlSi10Mg Mechanical Properties

| Property | As-Built | Heat Treated |

|---|---|---|

| Ultimate Tensile Strength | ~300 MPa | ~420 MPa |

| Yield Strength (Rp 0.2% offset) | ~160 MPa | ~290 MPa |

| Elongation at Break | ~8% | 3-5% |

| Hardness | ~80 HBW | ~130 HBW |

Factors influencing properties: Build orientation, layer thickness, laser parameters, heat treatment, machining

Heat treatment: Solution heat treatment followed by aging treatment

Key advantages: Higher strength-to-weight ratio than steel, good corrosion resistance

Printing AlSi10Mg for Metal 3D Printing

AlSi10Mg requires optimized printing parameters tailored to the metal 3D printing process used to achieve fully dense parts with good mechanicals.

Printing AlSi10Mg: Process Comparison

| SLM | EBM | DMLS | |

|---|---|---|---|

| Build chamber | Inert argon | Vacuum | Inert argon |

| Heat source | Fiber laser | Electron beam | Ytterbium laser |

| Beam deflection | Galvo scanner | Magnetic coils | Galvo scanner |

| Layer thickness (μm) | 20 – 100 | 50 – 200 | 20 – 100 |

| Typical scanning speed (m/s) | Up to 10 | Up to 10 | Up to 7 |

| Beam focus (μm) ≤100 | ≥200 | ≤100 | |

| **Min feature size (mm)**≤1 | ≥2 | ≤1 | |

| Surface finish (Ra) | 8 – 15 μm | 15 – 25 μm | 8 – 15 μm |

Key printing guidelines:

- Maintain consistent heat input between layers

- Use support structures for overhangs >45°

- Orient parts to reduce residuals stress

- Apply uniform layer thickness and hatch spacing

Post-Processing: Heat treatment, Hot Isostatic Pressing (HIP), machining, grinding, polishing

AlSi10Mg Applications in 3D Printing

The lightweight, strong and corrosion-resistant AlSi10Mg alloy sees wide use aerospace, automotive, industrial and healthcare sectors.

| Industry | Applications | Benefits |

|---|---|---|

| Aerospace | Structural brackets, airframe components, heat exchangers | ● Lightweighting ● Good strength at elevated temps ● Corrosion resistance |

| Automotive | Lightweight chassis, powertrain parts, custom trims | ● Lightweighting ● High strength-to-weight |

| Industrial | Lightweight structures, manifolds, heat sinks | ● Corrosion resistance ● Thermal conductivity ● Cost-effectiveness |

| Healthcare | Custom orthopedic implants, surgical instruments | ● Biocompatible ● Lightweight ● Higher accuracy |

- AlSi10Mg enables lightweight structures not manufacturable by conventional methods

- Ability to consolidate parts and optimize topology unlocks performance gains

- Customized low volume production viable with 3D printing compared to casting processes

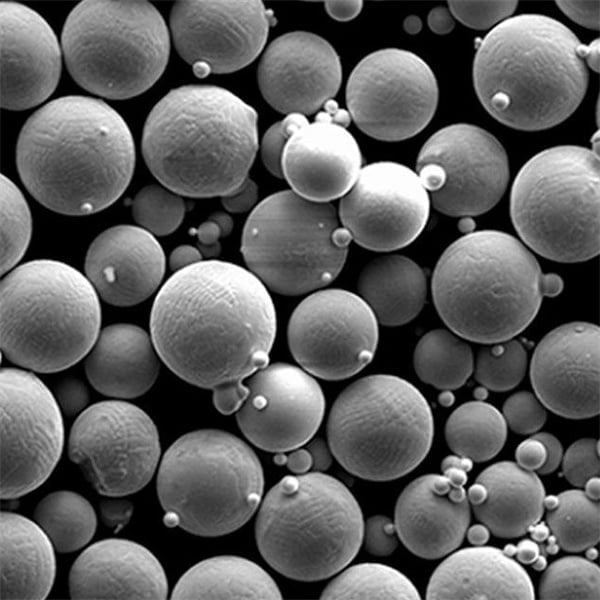

Where to Buy AlSi10Mg Powder for Additive Manufacturing

High purity AlSi10Mg powder tailored for AM processes is available from leading metal powder suppliers:

AlSi10Mg Powder Suppliers

| Supplier | Product Designation | Powder Morphology |

|---|---|---|

| Met3DP | AlSi10Mg | Spherical |

| Sandvik Osprey | Osprey AlSi10Mg | Spherical |

| Carpenter Additive | AlSi10Mg | Atomized |

| AP&C | AlSi10Mg Performance | Spherical |

| SLM Solutions | AlSi10Mg | Spherical |

- Price range $100-150 USD/kg

- Buy from reputable suppliers providing full composition and particle size distribution data

- Use fine powder (~25-45 μm) with good flowability and high density

Key powder attributes:

- Sphericity >85% optimal, Flowability >25s/50g using Hall flowmeter funnel

AlSi10Mg Powder Price Per Kilogram

The price of AlSi10Mg powder for metal 3D printing depends on factors like:

- Powder quality and sphericity

- Purchase quantity

- Supplier brand

Typical price range: $100 – $150 per kg

Bulk orders >500 kg offer maximum cost savings. Small R&D quantities <5 kg are sold at premium prices.

AlSi10Mg Price Per Kg – Comparison

| Supplier | Powder Type | Price Per Kg |

|---|---|---|

| Met3DP | AlSi10Mg | $120 |

| Sandvik Osprey | AlSi10Mg Osprey | $130 |

| Carpenter Additive | Gas atomized | $150 |

| SLM Solutions | AlSi10Mg Eiger | $130 |

- Prices indicative for 1 kg

- Custom alloys and tighter sieving available at higher price points

- Asia-Pacific prices approx. 20% lower

Cost Saving Tips:

- Compare prices across several leading suppliers

- Purchase higher volumes for quantity discounts up to 40% lower rate per kg

- Consider using lower grade powders for prototyping before final application

So shop competitive bids and discuss optimal powder specification and budgets with AM experts when buying AlSi10Mg for your metal 3D printing needs.

Design Guidelines and Limitations of AlSi10Mg Parts

Consider the alloys properties and AM process constraints when designing AlSi10Mg parts:

AlSi10Mg Design Rules

| Feature | Rule of Thumb | Reason |

|---|---|---|

| Wall thickness | 1-2 mm | Limit porosity, achievable surface finish |

| Overhang angles | > 45° unsupported | Prevent deformation, improve precision |

| Holes/cylinders | >Vertical, >Ø 5 mm | Prevent inaccuracies in horizontal holes |

| Fine features | >0.5-1 mm | Limited by AM process resolution |

| Tolerances | ± 0.2% or ±150 μm | Account for shrinkage, thermal stresses |

- Minimize large overhangs, unsupported geometries

- Include structural supports to prevent warpage, preserve tolerances

- Orient to reduce residual stresses due to thermal gradients

Post-Machining

- Heat treatment reduces machinability

- Finish machining commonly required for precision holes, fits

Limitations vs Cast Parts:

- Higher cost for small volumes <100 units

- Maximum part size constrained by printer dimensions

Frequently Asked Questions on AlSi10Mg Alloy

Q: Is AlSi10Mg readily weldable?

A: Yes, AlSi10Mg can be welded using welding processes like TIG welding. Use 4043 aluminum filler alloy. It has excellent weldability compared to higher strength 2xxx and 7xxx aluminum alloys.

Q: Can you sand/polish AlSi10Mg parts?

A: AlSi10Mg printed parts can be sanded, machined, grinded and mechanically or chemically polished to achieve smooth surface finishes. Post-processing is easier before solution heat treatment and aging when the alloy is softer.

Q: Is AlSi10Mg biocompatible for medical implants?

A: Yes, once the right post-processing is done AlSi10Mg conforms to ASTM F3001 for graded implant materials. Ensure density >99.5% and proper cell growth testing before use.

Q: Does AlSi10Mg require heat treating?

A: Solution heat treatment (540°C) followed by aging (150-170°C) is strongly recommended to get optimal mechanical properties and hardness from precipitation hardening.

Q: What precision and surface finish is achievable with AlSi10Mg parts?

A: Dimensional accuracy up to ±100 μm is possible for AlSi10Mg AM parts. As-built surface roughness ranges 8-15 μm (Ra) after medium quality finish machining, improving to <1 μm for precision CNC machining.