Imagine a world where complex metal parts can be conjured from thin air, with intricate designs and lightweight properties that were once impossible. This is the reality of aluminum alloy 3D printed metal powder, a revolutionary technology that’s transforming the metal manufacturing landscape.

This article delves deep into the world of aluminum alloy 3D printing metal powder, exploring its advantages, applications, different powder types, and addressing some frequently asked questions. So, buckle up and get ready to explore the exciting world of metal printing!

The Advantages of Aluminum alloy 3D printed metal powder

Aluminum alloys are some of the most versatile and widely used metals globally. But traditional manufacturing processes often come with limitations. 3D printing metal powder disrupts the game by offering a plethora of advantages:

- Design Freedom: Unleash your creativity! Unlike traditional methods restricted by subtractive manufacturing (removing material), 3D printing allows for complex geometries, internal channels, and intricate lattice structures. Imagine creating lightweight yet incredibly strong components – a game-changer for aerospace and automotive industries.

- Lightweighting: Aluminum is already known for its lightness, but 3D printing takes it a step further. By creating parts with internal lattices and optimized designs, you can significantly reduce weight while maintaining strength – a crucial aspect for fuel efficiency in airplanes and cars.

- Rapid Prototyping: Gone are the days of lengthy and expensive prototyping processes. 3D printing allows for quick and cost-effective creation of prototypes, accelerating the design iteration cycle and speeding up product development.

- Reduced Waste: Traditional manufacturing often generates significant scrap metal. 3D printing, on the other hand, uses a highly targeted approach, minimizing waste and making it a more sustainable option.

- Mass Customization: Imagine producing small batches of customized parts on-demand. 3D printing allows for this flexibility, catering to niche applications or personalized products without the need for large production runs.

Applications of Aluminum Alloy 3D Printing Metal Powder

The applications of aluminum alloy 3D printed metal powder are vast and constantly expanding. Here are some key areas where this technology is making waves:

- Aerospace: The relentless pursuit of lightweight and high-strength materials makes aluminum alloy 3D printing a perfect fit for the aerospace industry. Complex brackets, structural components, and even heat exchangers can be printed, leading to lighter aircraft with improved fuel efficiency.

- Automotive: Similar to aerospace, the automotive industry is embracing 3D printing for weight reduction and design innovation. Think custom components for high-performance cars, lightweight yet sturdy parts for electric vehicles, and even intricate designs for internal combustion engine components.

- Medical Implants: The ability to create customized implants with biocompatible aluminum alloys is revolutionizing the medical field. Imagine creating personalized prosthetic limbs, intricate joint replacements, or even custom cranial implants that perfectly match a patient’s anatomy.

- Consumer Goods: 3D printing is finding its way into consumer products too. Think of lightweight camera components, custom-designed bicycle frames, or even intricate jewelry pieces created on-demand. The possibilities are truly endless!

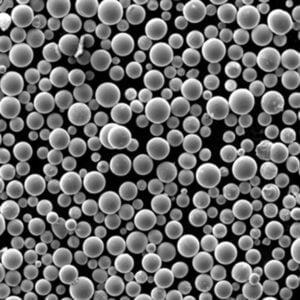

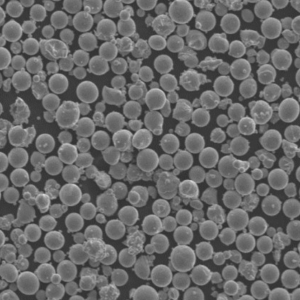

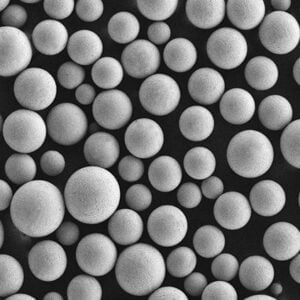

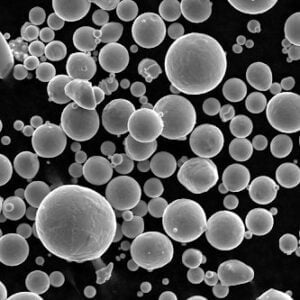

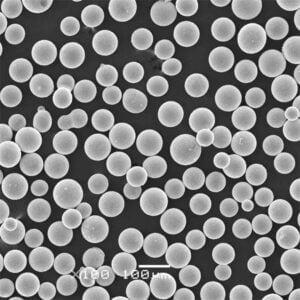

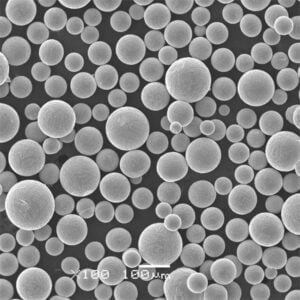

Types of Aluminum alloy 3D printed metal powder

The magic behind aluminum alloy 3D printing lies in the metal powder itself. But not all powders are created equal. Here’s a breakdown of some commonly used types:

| Aluminum Alloy | Key Characteristics | Applications |

|---|---|---|

| AlSi10Mg | Excellent castability, good strength, and weldability. | Widely used for general-purpose applications, automotive components, and structural parts. |

| AlSi7Mg | Similar to AlSi10Mg but with slightly lower silicon content, offering good castability and machinability. | Suitable for applications requiring good surface finish and machinability alongside good strength. |

| Scalmalloy | A high-strength aluminum alloy with excellent fatigue resistance. | Ideal for aerospace applications where lightweight and high-strength components are crucial. |

| Maraging Aluminum | Offers exceptional strength-to-weight ratio and high-temperature performance. | Used for demanding applications in aerospace and defense industries where high strength and temperature resistance are paramount. |

Beyond the table: These are just a few examples, and the development of new aluminum alloy powders for 3D printing is an ongoing process. The choice of powder depends on the specific application’s requirements for strength, weight, heat resistance, and other factors.